11. Inspect the air induction system for loose fitting, damaged or missing

components and repair as necessary.

SERVICING YOUR WHEELS AND TIRES

Wheel assembly

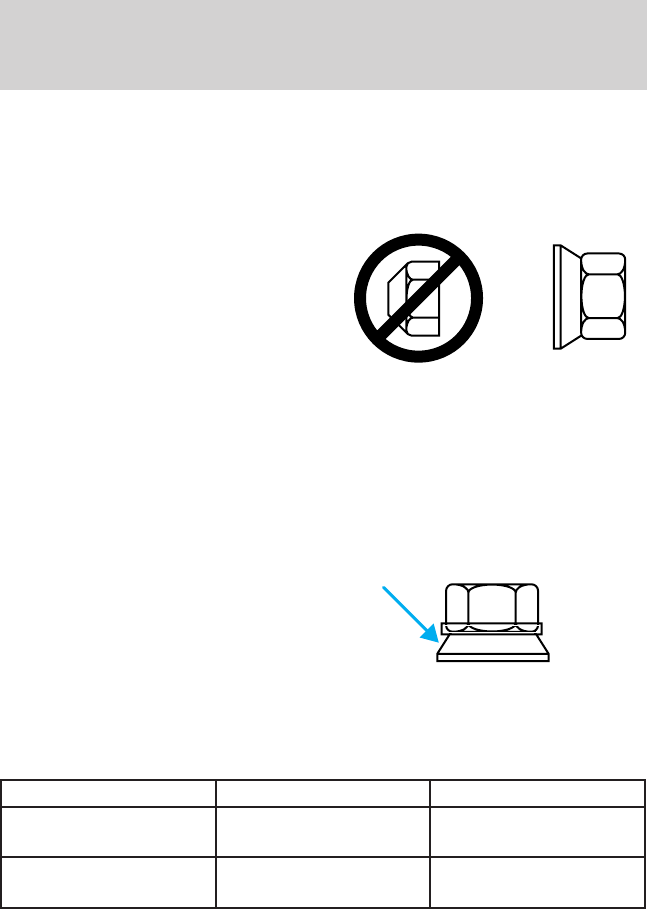

Your vehicle is fitted with hub

piloted wheels and two-element

swiveling lug nuts (20 & 22 mm).

Do not use taper type wheels or ball

seat wheel nuts.

• Do not paint the mating face of the hub/drum.

• Do not paint the two-element swiveling lug nuts or wheel stud.

• Do not allow an excessive thickness of paint to build between the disc

wheel mounting surfaces.

• Do not install disc wheels where the paint has not fully cured.

• At wheel changes, ensure mounting faces are clean and free of rust,

dirt and excess paint.

If fasteners are needed, use only Ford recommended replacement parts.

• To maintain the desired

torque/tension relation between

nut body and flange, it is

necessary to use clean engine oil

meeting Ford specification

WSS-M2C153-G between nut body and flange. Lubricate the nut body

and flange any time a wheel is removed.

The M20 & M22 wheel nuts are right-hand threads. Refer to the

following chart for approved wheel lug nut torque.

Wheel type Bolt size Wheel nut torque

10-hole disc 285.75

mm bolt circle

M22 (22 by 1.5 mm) 610-677 Nm (450-500

lb-ft)

8-hole disc 19.5x6.75

mm bolt circle

M20 (20 by 1.5 mm) 610-677 Nm (450-500

lb-ft)

The disc wheel nuts on your vehicle were tightened before delivery.

Recheck torque of nuts at 160 km (100 miles) and 800 km (500 miles) of

new vehicle operation or any time a wheel is removed. Reset to

recommended torque levels.

Maintenance and Specifications

210