Maintenance

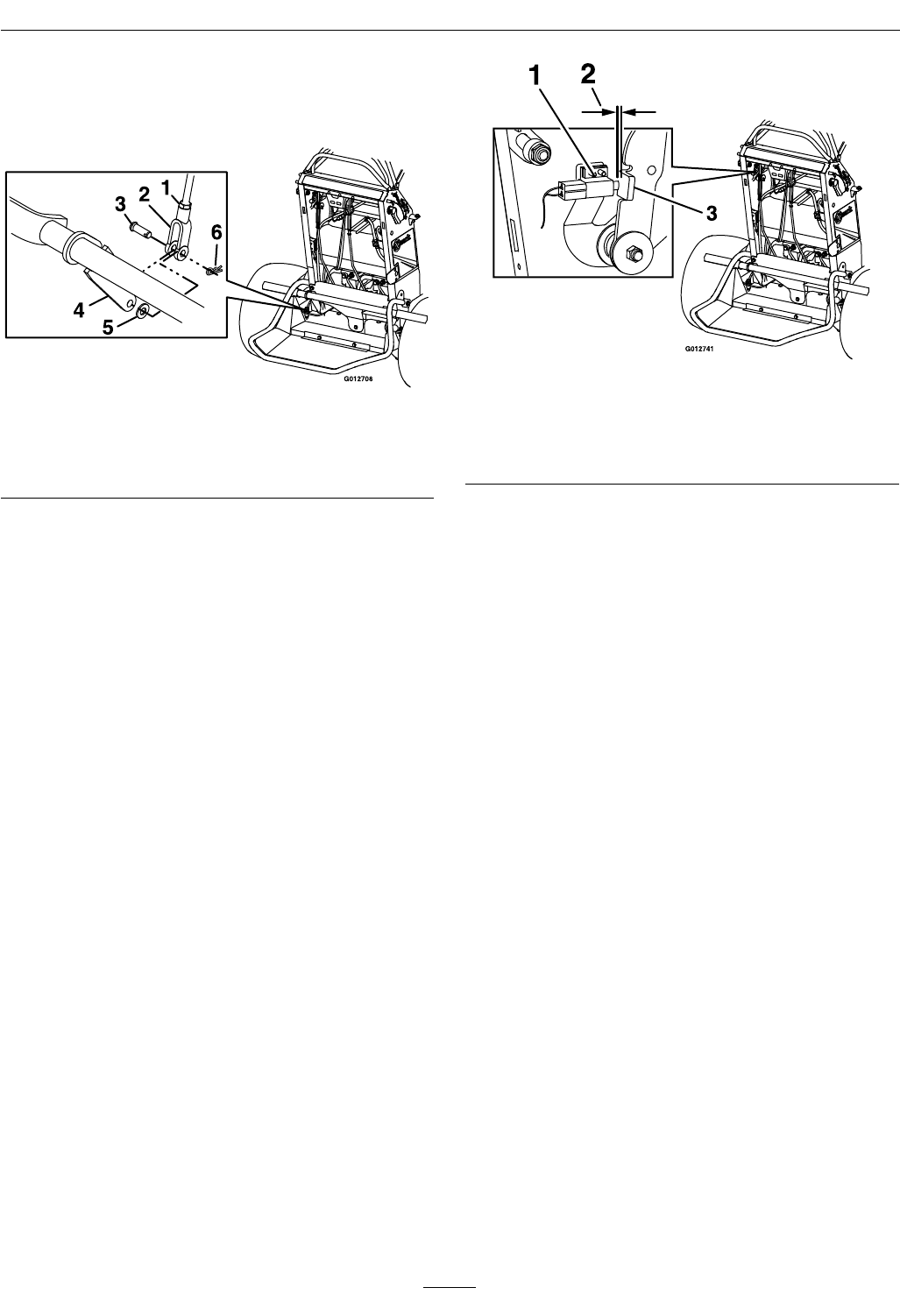

4. To adjust the brake, remove the hairpin, washer,

and clevis pin from the lower brake lever and yoke

as shown in Figure 28.

Figure 28

1. Jam nut 4. Lower brake lever

2. Yoke 5. Washer

3. Clevis pin

6. Hairpin

5. Loosen the jam nut.

6. Rotate the yoke. To tighten the brake, rotate the

yoke up. To loosen the brake, rotate the yoke

down.

Note: The brake rod should be threaded into

both yokes the same distance.

7. Secure the yoke to lower brake lever with the

hairpin, washer, and clevis pin.

8. Tighten the jam nut.

9. Check the brake operation again.

10. After the brake is adjusted, the lever switch needs

to be checked.

11. Check the gap between the brake lever and the

switch as shown in Figure 29. The gap needs to

be an 1/8 inch (3mm) with the brake engaged.

Figure 29

1. Switch

3. Brake lever

2. 1/8 inch (3mm) gap

needed between switch

and brake lever

12. If needed, loosen the screws holding the switch

and adjust the switch.

Electric Clutch Adjustment

Service Interval: Every 100 hours

The clutch is adjustable to ensure proper engagement

and proper braking.

1. Stop engine, wait for all moving parts to stop,

and remove key. Engage parking brake. Allow

the machine to cool completely before starting

these instructions.

2. Insert a 0.015–0.021 inch (0.381–0.533 mm)

feeler gauge through one inspection slot in the

side of the assembly. Make sure it is between the

armature and the rotor friction surfaces.

3. The gap should be at least 0.015 (0.381 mm) and

not more than 0.021 (0.533 mm). If adjustment is

needed, then set at 0.015 (0.381 mm) for each of

the three adjustment slot positions.

4. Tighten the lock nuts until there is slight binding

on the feeler gauge but it can be moved easily

within the air gap (see Figure 30).

38