Maintenance

2. Carefully clean area around lter. It is important

that no dirt or contamination enter hydraulic

system.

3. Unscrew lter to remove and allow oil to drain

from reservoir.

Important: Before reinstalling new lter, ll

it with Exmark Premium Hydro oil and apply

a thin coat of oil on the surface of the rubber

seal.

Turn lter clockwise until rubber seal contacts the

lter adapter, then tighten the lter an additional

2/3 to 3/4 turn.

4. Fill reservoir as stated in Check Hydraulic Oil

Level.

Exmark Premium Hydro Oil is recommended.

Refer to the chart for an acceptable alternative:

Hydro Oil

Change Interval

Exmark Premium Hydro

Oil (Preferred)

500 Hours

Mobil 1 15W50

250 Hours

5. Loosen lter 1/2 turn and allow a small amount

of oil to leak from the oil lter (this allows air to

be purged from the oil lter and supply hose from

the hydraulic reservoir). Turn lter clockwise

until rubber seal contacts the lter adapter. Then

tighten the lter an additional 2/3 to 3/4 turn.

6. Raise the rear of machine up and support with

jack stands (or equivalent support) just high

enough to allow drive wheels to turn freely.

CAUTION

Raising the mower deck for service or

maintenance relying solely on mechanical

or hydraulic jacks could be dangerous. The

mechanical or hydraulic jacks may not be

enough support or may malfunction allowing

the unit to fall, which could cause injury.

Do Not rely solely on mechanical or hydraulic

jacks for support. Use adequate jack stands

or equivalent support.

7. If either drive wheel does not rotate, one or both

of the charge pumps (located on the top of the

main pump as shown in Figure 21) may have lost

their “prime”. Refer to Hydraulic System Air

Purge section.

Note: Do Not change hydraulic system oil (except

for what can be drained when changing lter), unless

it is felt the oil has been contaminated or been

extremely hot.

Changing oil unnecessarily could damage hydraulic

system by introducing contaminates into the system.

Hydraulic System Air Purge

Service Interval: As required

Air must be purged from the hydraulic system

when any hydraulic components, including oil

lter, are removed or any of the hydraulic lines are

disconnected.

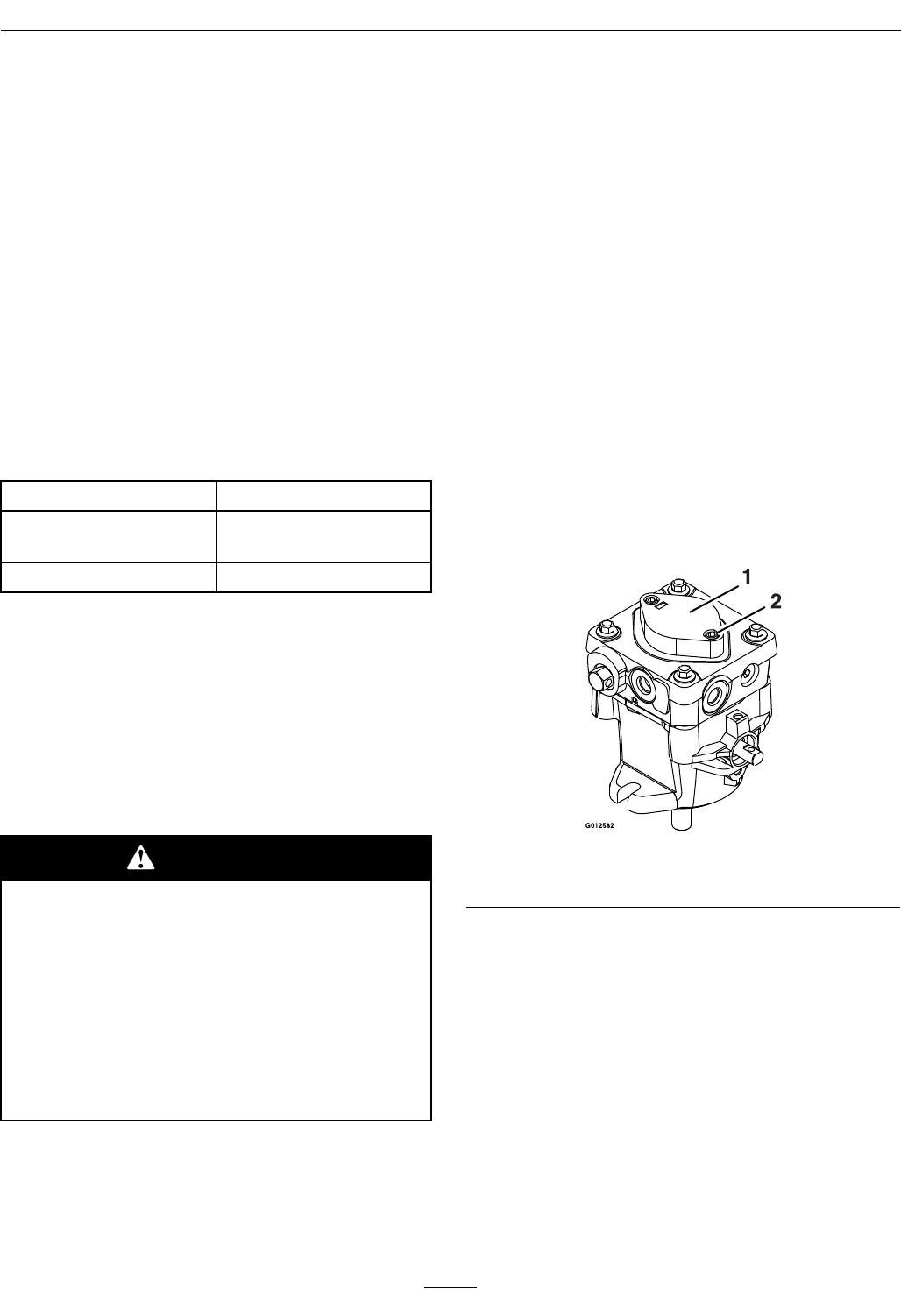

The critical area for purging air from the hydraulic

system is between the oil reservoir and each

charge pump located on the top of each variable

displacement pump (Figure 21). Air in other parts of

the hydraulic system will be purged through normal

operation once the charge pump is “primed”.

Figure 21

1. Charge pump cap 2. Loosen 1 1/2 turns only

1. Stop engine and wait for all moving parts to stop.

Raise the rear of the machine up onto jack stands

high enough to raise the drive wheels off the

ground.

2. Check oil level as stated in Check Hydraulic Oil

Level section.

3. Start engine and move throttle control ahead to

full throttle position. Move RH motion control

lever inward (together) and move both levers

forward with equal pressure.

If either drive wheel does not rotate, it is possible

to assist the purging of the charge pump by

carefully rotating the tire in the forward position.

33