April 1, 2006 10 Lit. No. B64090, Rev. 00

TORQUE SPECIFICATIONS

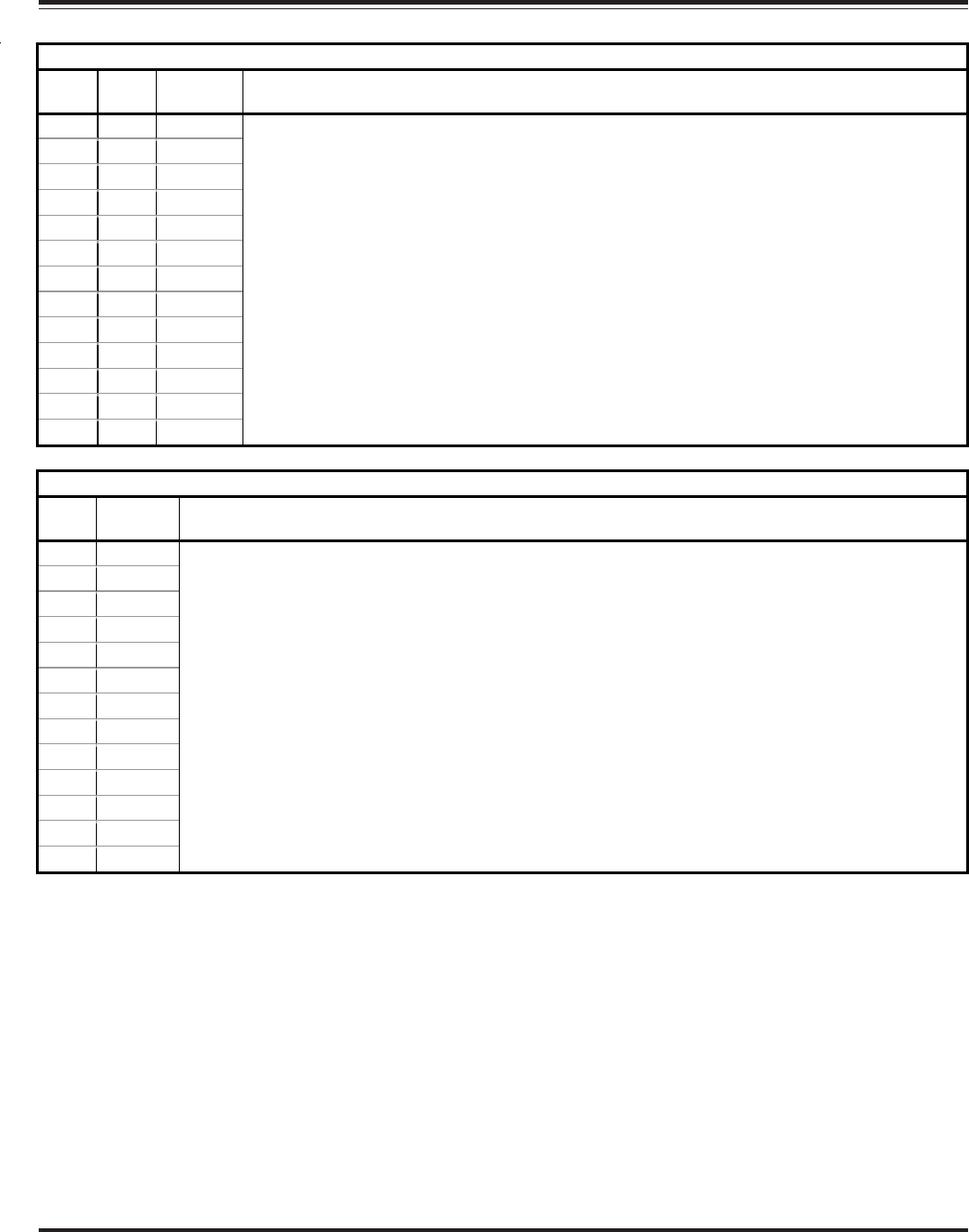

37° JIC Flare Torque Values

Turns Size

Ft-lbs

min.max

Assembly Steps

N/A -02 6-7

N/A -03 8-9

2 -04 11-12

2 -05 14-15

1-1/2 -06 18-20

1-1/2 -08 36-39

1-1/2 -10 57-63

1-1/4 -12 79-88

1 -14 94-103

1 -16 108-113

1 -20 127-133

1 -24 158-167

1 -32 245-258

1. Make sure the tubing and threads are clean.

2. Lubricate the threads with 10W hydraulic oil.

3. Hand tighten the nut/sleeve to approx. 30 in-lbs.

4. Make alignment marks on the nut and fitting.

5. Tighten to turn or torque specification.

6. When fully tightened, make a 2

nd

set of alignment marks at the fully tighten positioned.

NOTE: Torque values specified are for threads lubricated with 10W hydraulic oil.

Over tightening will reduce the clamping force resulting in loss of seal and reduction of flow.

O-Ring Boss Torque Values

Size

Ft-lbs

min.max

Assembly Steps

-02 6-7

-03 8-10

-04 13-15

-05 17-21

-06 22-25

-08 40-43

-10 43-57

-12 68-75

-14 90-99

-16 112-123

-20 146-200

-24 154-215

-32 218-290

1. Verify the port, o-ring, sealing surfaces and threads are clean and free of damage.

2. Lubricate the threads and the o-ring with 10W hydraulic oil.

3. For an adjustable O.R.B., completely back off the lock nut and washer.

4. Hand tighten the fitting until it contacts the port spotface. Point the elbow or tee in the desired direction

and hold.

5. Torque to specification.

NOTE: Torque values specified are for threads lubricated with 10W hydraulic oil.