141-072011 - 201/203 Series Page 17 of 23

3.5. Valve:

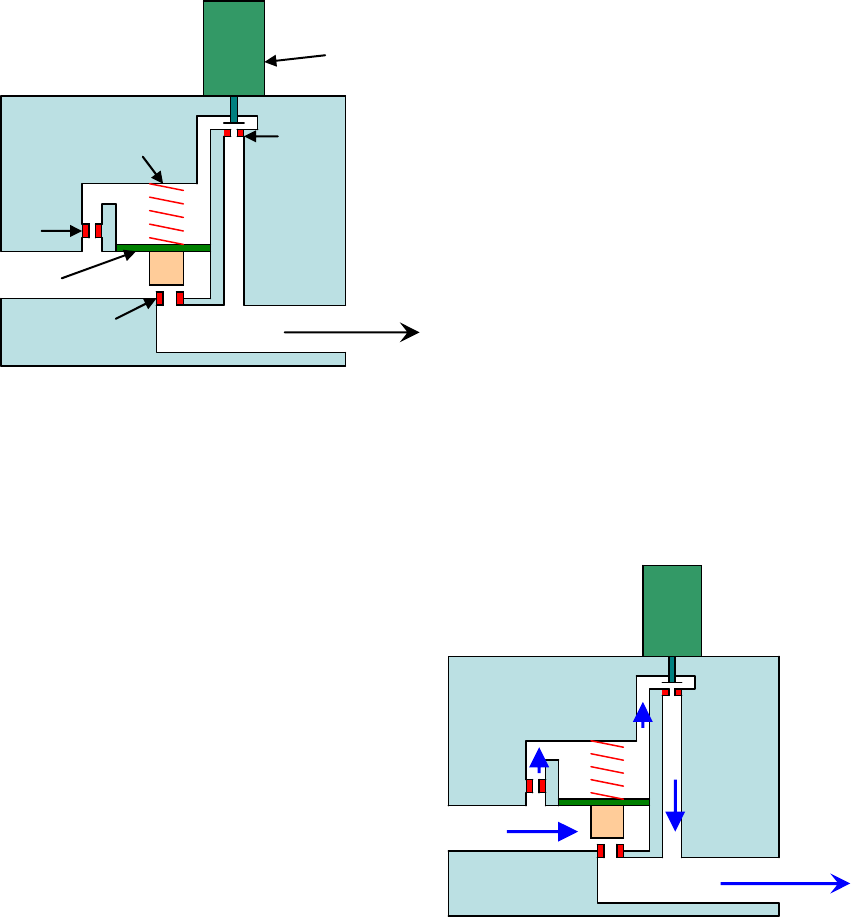

A solenoid valve is used as a pilot valve to control a much larger pneumatic diaphragm valve. The

pilot valve is an “automatic metering solenoid” valve. While most solenoids operate in either the

fully open or fully closed state, the automatic metering solenoid valve is designed to control flow (see

Figure 3.5). A spring, connected to the plunger assembly, holds a magnetic plunger tightly against

an orifice to shut off flow. The magnetic plunger is surrounded by an electrical coil, which when

energized with electrical current lifts the plunger off the orifice and allows flow to pass between the

orifice and the plunger seat. Controlling the current through the coil controls the distance between

the orifice and the plunger seat, thus effectively controlling the flow through the valve.

The main valve used in the HFC-203/207 is

a pilot operated pneumatic valve. The main

pneumatic valve uses a diaphragm to control

the height of the main seat above the orifice.

The diaphragm position is controlled by

balancing competing forces from the main

spring and the pressure difference between

the valve upstream pressure and the pressure

in the bonnet chamber.

The bonnet pressure is controlled by the

solenoid operated pilot valve. When

pressure is first applied and the pilot valve is

closed, system pressure P

u

is much higher

than the bonnet pressure P

b

. P

u

will push up

the diaphragm against P

b

and the main flow

will initiate. Flow through the restriction of the bleed screw Q

b

will also initiate. Since Q

b

is flowing

into the bonnet chamber and the pilot flow Q

p

is shut off this will pressurize the bonnet chamber and

P

b

will rise. When the force due to the pressure difference across the diaphragm is balanced by the

closing force from the main spring, the main valve will close.

In order to open the valve, power is

applied to the solenoid. The generated

magnetic field attracts the plunger toward

the pole against spring force. Flow

initiates through the pilot valve Q

p

. When

the pilot flow exceeds the bleed screw flow

the pressure in the bonnet chamber will

start to drop.

When the force due to the pressure

difference across the diaphragm exceeds

the closing spring force then the

diaphragm will start to lift. As the

diaphragm moves up it will open the main

valve and allow flow through the main

orifice.

The control loop maintains sufficient power to the solenoid to keep the pilot valve flow equal to the

bleed screw flow when the bonnet pressure is at the right level to hold the diaphragm high enough

that the desired flow passes through the main valve.

Solenoid

Pilot

Bleed

Screw

Main

Orifice

Main

Spring

Diaphragm

Pilot

Flow Q

p

P

d

Bleed

Flow Q

b

P

u

P

b

Main Flow Q

m

(F