141-072011 - 201/203 Series Page 13 of 23

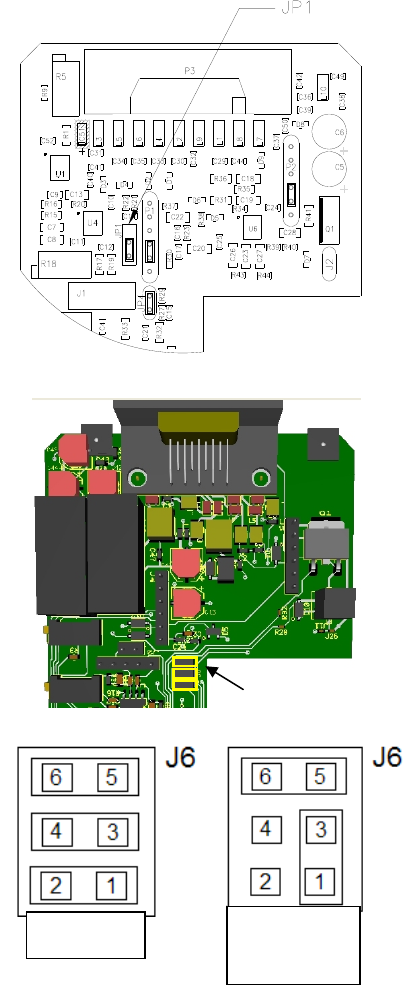

2.6.7. Operation with an external sensor. (Fig. 2.2)

In some instances, it might be desirable to use an external sensor to provide process information to

the control circuitry in the flow controller. For example, you might want to control the pressure in a

vacuum system by adjusting the rate at which the system is backfilled with a gas. The new,

enhanced HFC series of flow controllers have provision for accepting a 0 - 5VDC (or 0 - 10 VDC)

output from an external sensor at pin 13 of the DA-15 (±15 Volt), Pin 1 of the DE-9 (24 Volt)

connector. To activate this feature, the cover of the HFC must be removed to gain access to the

electronics card and move a jumper.

For the 15 Volts units JP1 is a three pin jumper block located just below the “D” connector. In the

normal operating mode, the jumper covers the bottom two pins. To select “External Sensor”, move

the jumper to the upper two pins. This swaps the flow input to the controller circuit from the flow

meter output to pin 13 of the “DA-15” connector.

For the 24 Volt units JP6 is a six pin jumper block located

just to the right of the sensor connector. Pin 1 is in the

lower right corner. There are three jumpers installed

horizontally. The bottom jumper ties the flow output to

the valve control circuit and the middle jumper ties Pin 1

of the DE-9 connector to reference voltage circuit.

Remove both of the lower two jumpers and reinstall one

jumper vertically between the outside two pins (pins 1 &

3). This will tie Pin 1 of the DE-9 connector to the valve

control circuit and allow the controller to maintain the

external process variable equal to the desired setpoint.

The 5 Volt reference is not available in this configuration.

2.6.8. Response to Command Changes

The response of the control circuit to changes to the

command signal is set at the factory for fast, stable response.

If excessive overshoot is present, the response can be slowed

removing the jumper labeled “JP4,” located in the center of

PC-828 for the 15 Volt units or by removing the top jumper

of JP6 for the 24 Volt boards (located to the right of the

sensor connector.

The fastest response to command changes is obtained when

JP4/(JP6) is covered by the jumper. This setup allows large

overshoot and undershoot swings in the actual flow rate while

the control circuit is establishing control at the new command

point. A slower response to command changes is obtained

when JP4/JP6 is not covered by a jumper. This setup results

in no overshoot or undershoot in the actual flow rate as the

controller circuit establishes control at the new command

point. This jumper does not affect the system gain and

will not dampen out oscillations.

To adjust the response, you need a means of producing a

step change in the command voltage from 10% of full

scale to 100% of full scale. Follow the steps outlined

below:

1) Cover the pins of JP4/JP6 with a jumper. (see fig. 2.2 & fig 2.3)

2) Set the command voltage to 10% of full scale. Allow the flow to stabilize.

Fi

g

2.2

JP6

Fig 2.3

Normal

External

Variable