ME(H4DOTC)-37

MECHANICAL

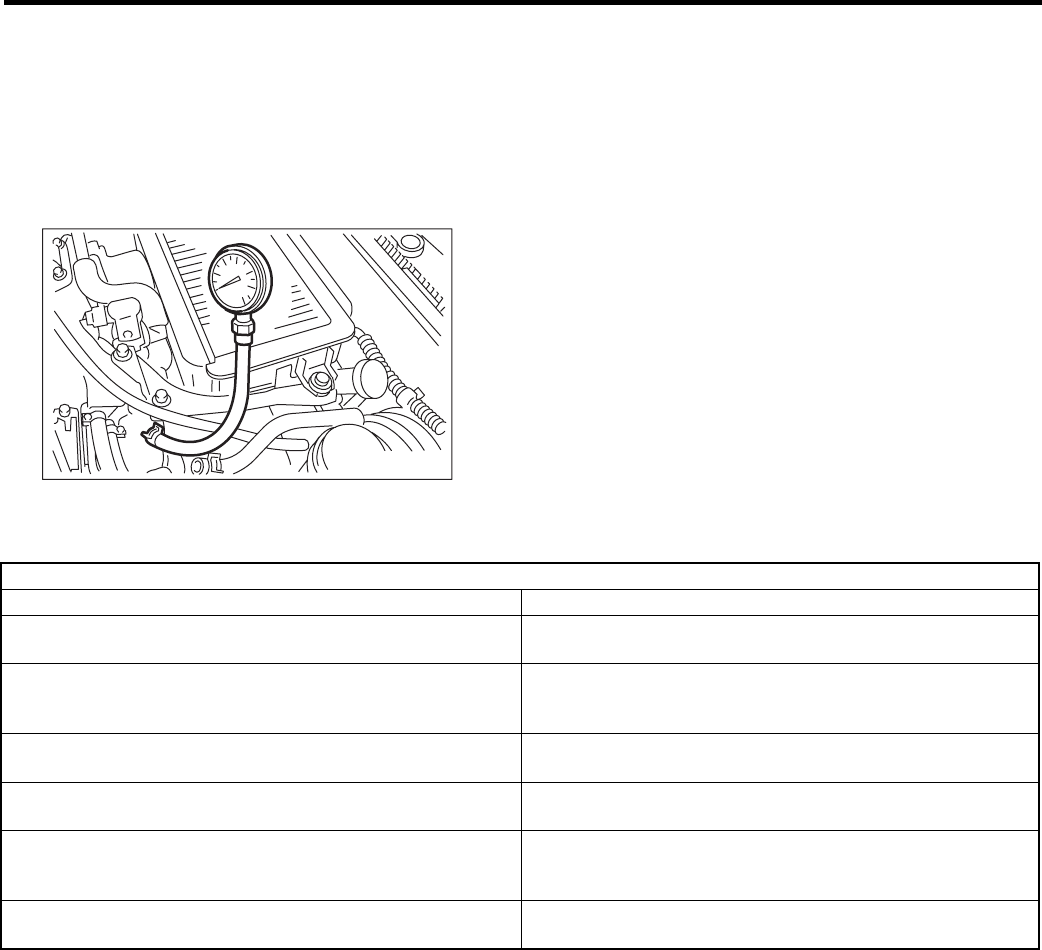

Intake Manifold Vacuum

5. Intake Manifold Vacuum

A: INSPECTION

1) Warm-up the engine.

2) Disconnect the brake vacuum hose, and then install the vacuum gauge to hose fitting on manifold.

3) Keep the engine at the idle speed, and then read the vacuum gauge indication.

By observing the gauge needle movement, the internal condition of engine can be diagnosed as described

below.

Vacuum pressure (at idling, A/C “OFF”):

Less than

−

−−

−

60.0 kPa (

−

−−

−

450 mmHg,

−

−−

−

17.72 inHg)

ME-00008

Diagnosis of engine condition by measurement of manifold vacuum

Vacuum gauge indication Possible engine condition

1. Needle is steady but lower than normal position. This ten-

dency becomes more evident as engine temperature rises.

Leakage around intake manifold gasket or disconnection or

damaged vacuum hose

2. When engine speed is reduced slowly from higher speed,

needle stops temporarily when it is lowering or becomes steady

above normal position.

Back pressure too high, or exhaust system clogged

3. Needle intermittently drops to position lower than normal

position.

Leakage around cylinder

4. Needle drops suddenly and intermittently from normal posi-

tion.

Sticky valves

5. When engine speed is gradually increased, needle begins to

vibrate rapidly at certain speed, and then vibration increases as

engine speed increases.

Weak or broken valve springs

6. Needle vibrates above and below normal position in narrow

range.

Defective ignition system or throttle chamber idle adjustment