10

TO CHANGE THE CURRENT SETTING:

1. Remove the hydraulic hose coupling from the return port

on the tool, if one is installed. When making the change from

CC to OC, hydraulic uid may be trapped in the tool, prevent-

ing complete movement of the adapter. Remove the return

coupling to allow the hydraulic uid to escape.

2. Loosen the 2 setscrews on the cylinder.

3. Turn the adapter until it stops:

• counter clockwise (CCW) to change to closed center

(creates gap)

• clockwise (CW) to change to open center (closes gap)

4. Tighten the two setscrews.

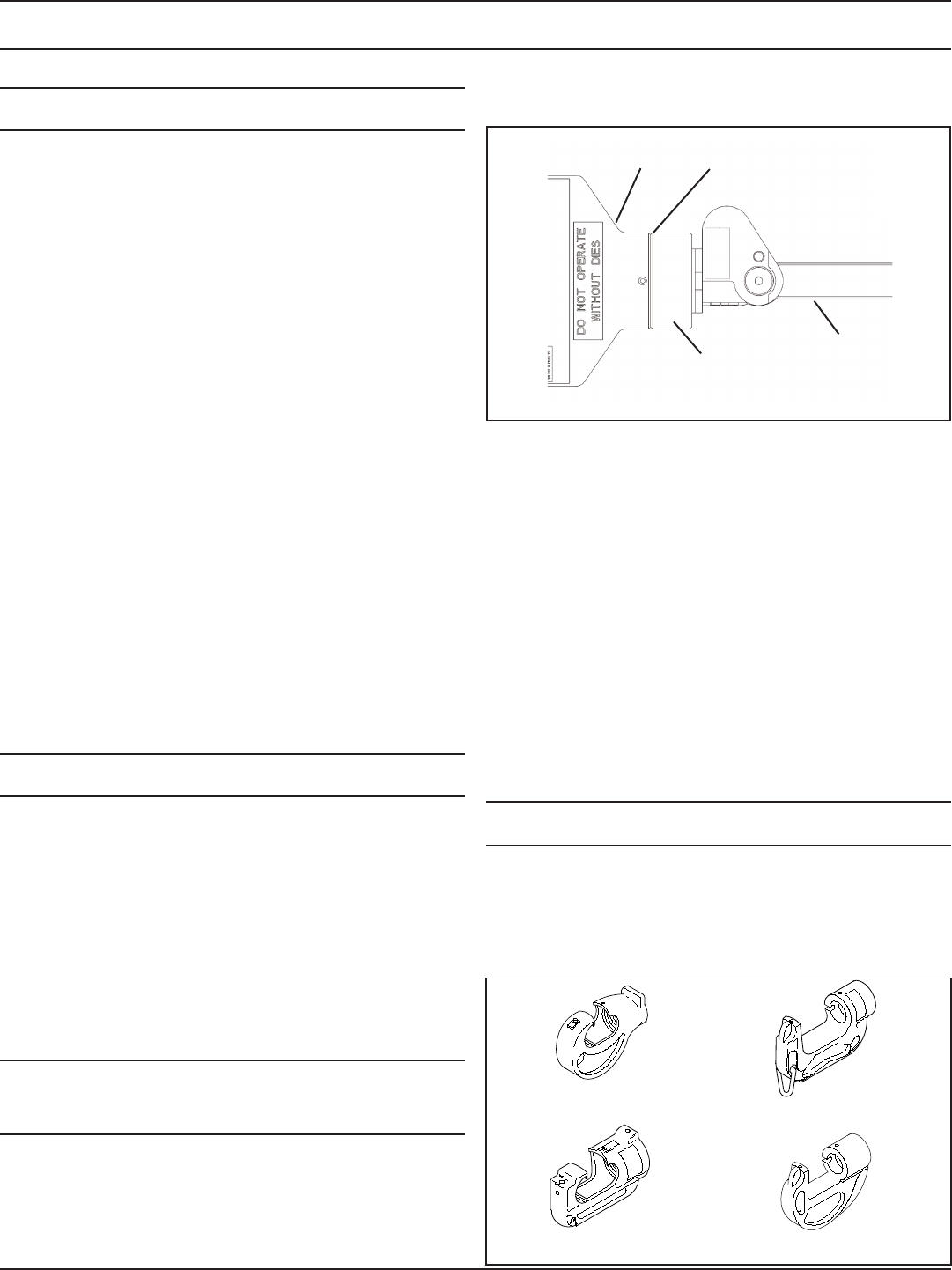

DIE INSTALLATION

One die is installed in the crimping head (Retainer Die Yoke

or C-frame) and the other die is installed onto the ram or

die piston assembly, depending on the model. See below to

identify the style of crimping head you have. Refer to the parts

illustrations in this manual for more detailed reference.

Open-Center (no gap)

Adapter

Cylinder

Trigger Handle

Top View of Tool

OPERATION

PRE-OPERATION

Careful inspection of the tool and hydraulic system before

startup is important for safe, reliable operation of the tool.

The following items should be checked daily at the start and

the end of each work shift.

1. Make sure the proper dies are securely in place. Operating

the tool without dies can deform the crimping heads. Refer to

Die Installation for instructions.

2. Connect hoses. Wipe all hose couplers with a clean, lint-

free cloth before making connections. Dirty couplers can

contaminate the hydraulic lines and prevent a good seal at

the connection.

3. Check all fasteners for tightness.

4. Check the equipment for oil leaks. If leaks are observed, do

not use the tool; have the equipment serviced before use.

5. Check the tool and hydraulic system for proper operation

and performance.

6. If the equipment does not appear to operate properly, have

it serviced before use.

7. Periodically verify the crimping force of the tool. Refer to

Die Load Verication.

SETUP AND TEST

Never operate the tool without dies. Operating without dies can

deform the crimping head (retainer die yoke or C-frame).

If this happens, the dies cannot be installed and the crimping

head must be replaced.

Never install the dies while the hydraulic hoses are connected

to the tool.

Verify the crimping force before operating the tool.

OPEN CENTER/CLOSED CENTER

SETUP

The CT10 Hydraulic Crimping Tool can be congured for either

open-center or closed-center operation. The current setting

is easily determined by looking at the gap between the adapter

and the cylinder:

Burndy Y35 & 30 mm Style

Retainer Die Yoke

Kearney WH3 Style

C-Frame

Stanley Y35 Style

Retainer Die Yoke

Kearney PH2 Style

C-Frame