7. Push the On/Off switch to the I (on) position.

The sealant and compressor kit injects sealant and

air into the tire. Sealant could leak from the

puncture until the vehicle is driven and the puncture

has sealed.

8. The pressure gage will initially show a high pressure

while the compressor pushes the sealant into the

tire. Once the sealant is completely dispersed in

the tire, the pressure will quickly drop and start to

rise again as the tire inflates.

9. Inflate the tire to the recommended inflation

pressure, found on the Tire and Loading Information

label located on the vehicle’s center pillar (B-pillar)

below the vehicle’s door latch, using the air

pressure gage on the top of the unit.

The pressure gage reads high while the compressor

is running. Turn the compressor off to get an

accurate pressure reading.

Notice: If the recommended pressure cannot be

reached after 15 minutes, the vehicle should not be

driven. The tire is too severely damaged and

cannot be inflated or sealed with the tire sealant

and compressor kit. Remove the air compressor

accessory plug from the accessory power outlet and

unscrew the sealant filling hose from the tire

valve or tire pressure monitoring sensor valve.

See Roadside Assistance Program on page 7-7.

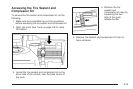

10. Push the sealant and compressor kit switch to

the O (off) position.

11. The tire is not sealed and will continue to leak air

until the vehicle is driven and the sealant is

distributed in the tire.

Steps 12 through 20 must be done right after

Step 11.

12. Unplug the air compressor accessory plug from the

accessory power outlet in the vehicle.

13. Disconnect the sealant filling hose from the tire

valve stem, by turning it counterclockwise, and

replace the tire valve stem cap.

Be careful when handling the tire inflator

components as they could be hot after usage.

14. Wrap the sealant filling hose around the air

compressor channel to stow it in its original location.

5-78