13.

MAINTENANCE

AND

STORAGE

13-1

DAILY

MAINTENANCE

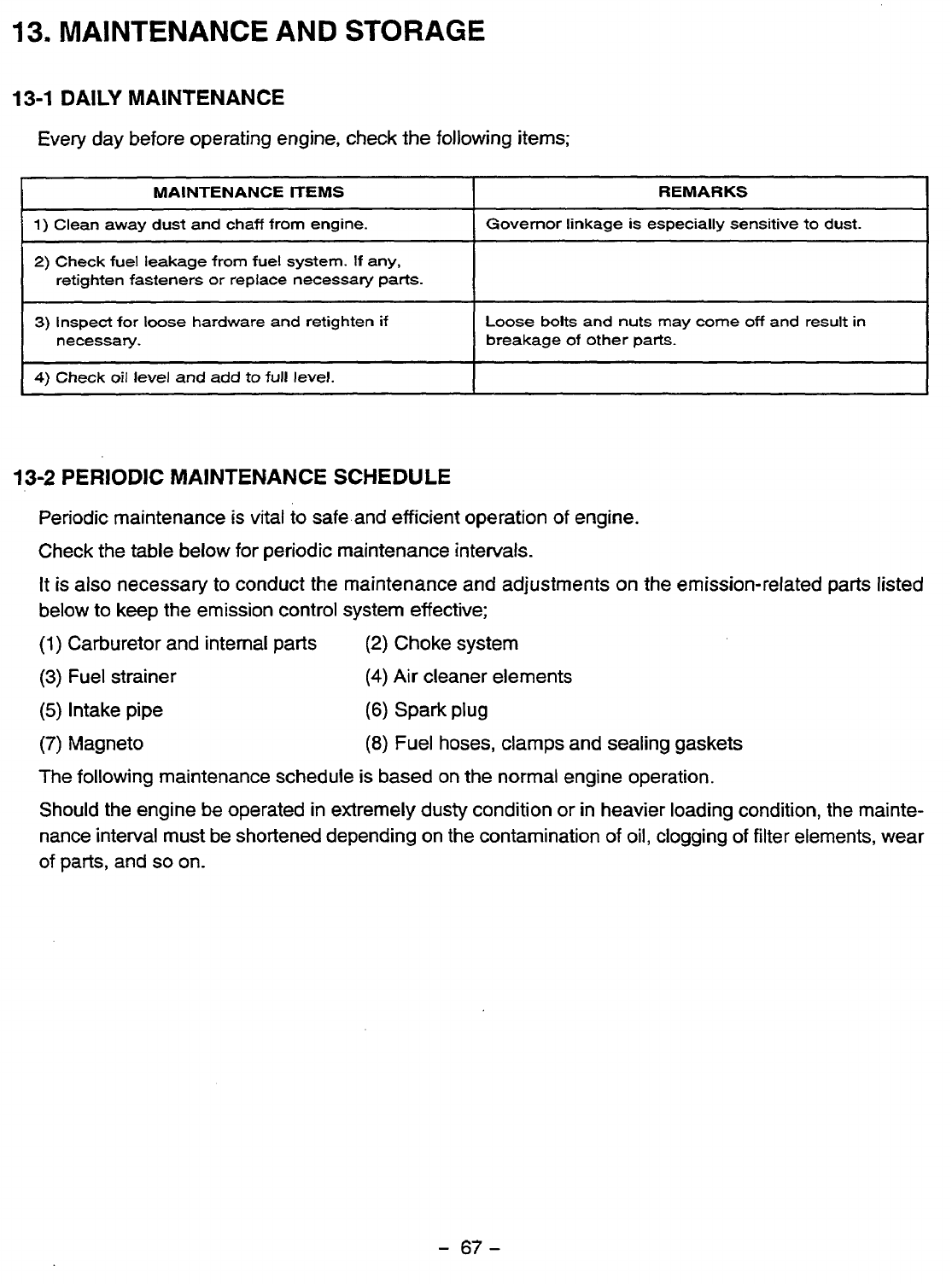

Every day before operating engine, check the following items;

__~

~~ ~~ ~ ~

MAINTENANCE

ITEMS

Governor linkage is especially sensitive to dust.

1)

Clean away dust and chaff from engine.

REMARKS

r

2)

Check fuel leakage from fuel system. If any,

retighten fasteners

or

replace necessary

parts.

~ ~~ ~

3)

Inspect for loose hardware and retighten if

Loose

bolts and nuts may come off and result in

necessary.

breakage

of

other parts.

4)

Check

oil

level

and add

to

full

level.

13-2

PERIODIC MAINTENANCE

SCHEDULE

Periodic maintenance is vital to safe.and efficient operation

of

engine.

Check the table below for periodic maintenance intervals.

It is also necessary

to

conduct the maintenance and adjustments on the emission-related parts listed

(1)

Carburetor and internal parts

(2)

Choke system

(3)

Fuel strainer

(4)

Air cleaner elements

(5)

Intake pipe

(6)

Spark

Plug

(7)

Magneto

(8)

Fuel hoses, clamps and sealing gaskets

The following maintenance schedule is based on the normal engine operation.

Should the engine be operated in extremely dusty condition

or

in heavier loading condition, the mainte-

nance interval must be shortened depending on the contamination

of

oil, clogging

of

filter elements, wear

of

parts, and so

on.

e

below to keep the emission control system effective;

-

67-