2)

PISTON

and CONNECTING

ROD

(1)

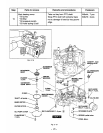

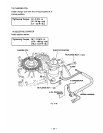

Install piston and connecting rod assembly into

cylinder by using a piston ring compressor to

hold piston rings.

Note:

The

"1

'I

mark

of

the

connecting

rod

for

#I

cylinder and

"2"

mark for

#2

cylin-

der

should

be

faced to the main bear-

ing cover side when assembled.

Apply

enough

oil

to piston rings,

con-

necting rod bearings (large end) and

cylinder bore before

assembly.

the illustration.

*

Set

gaps of piston rings

as

shown

in

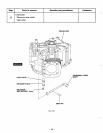

:2)

Temporary

fit flywheel and

turn

crankshaft

to

BTDC

(bottom dead center). Lightly tap the

top

of

piston until large end

of

the rod meet

the pin portion

of

crankshaft.

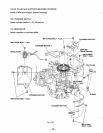

(3)

Set connecting rod cap to connecting rod with

the alignment marks mated and the clinching

portion clinched. Tighten

bolts

by the speci-

fied torque.

Tightening Torque

:

22.1

-

27.0

N-m

(225

-

275

kg-cm)

(1

6.3

-

19.9

ft-lb.)

(4)

Check for free movement

of

piston and con-

necting rod

by

turning crankshaft

slowly.

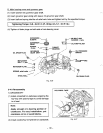

3)

TAPPFT

and

CAMSHAFT

(1)

Apply oil to tappets and install in their original

position. Push in fully to avoid damage during

camshaft installation.

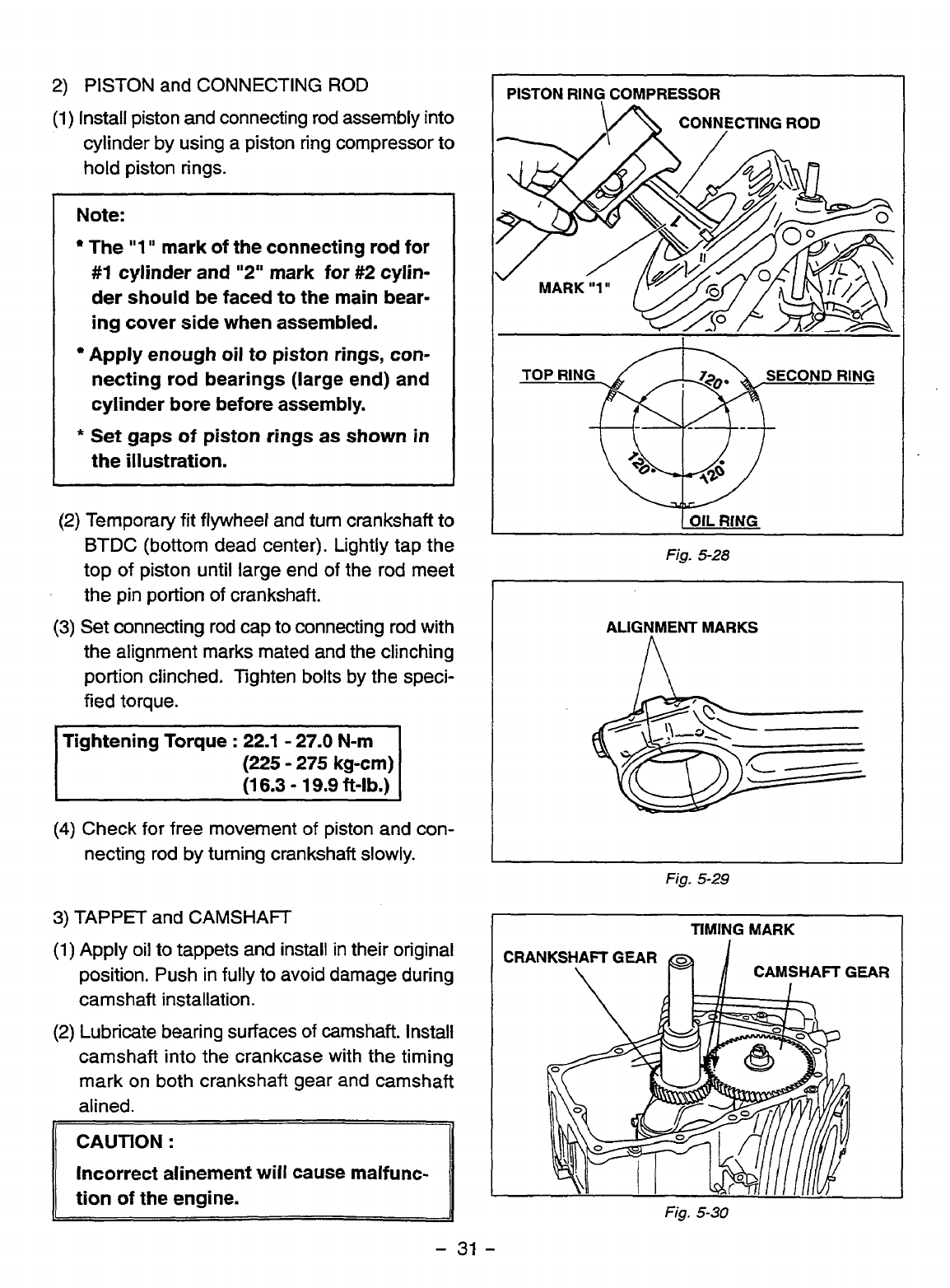

(2)

Lubricate

bearing surfaces

of

camshaft. Install

camshaft into the crankcase with the timing

mark on both crankshaft gear and camshaft

alined.

CAUTION

:

Incorrect

alinement

will cause malfunc-

tion

of

the

engine.

PISTON RING COMPRESSOR

\A

CONNECTING ROD

Fig.

5-28

ALIGNMENT MARKS

n

Fig.

5-29

TIMING

MARK

CRANKSHAFT

GEAR

\

//

CAMSHAFTGEAR

Fig.

5-30

-

31

-