113

MAINTENANCE

Track Maintenance

Track Inspection

1. Using a hoist, safely lift and

support the rear of the snow-

mobile off the ground.

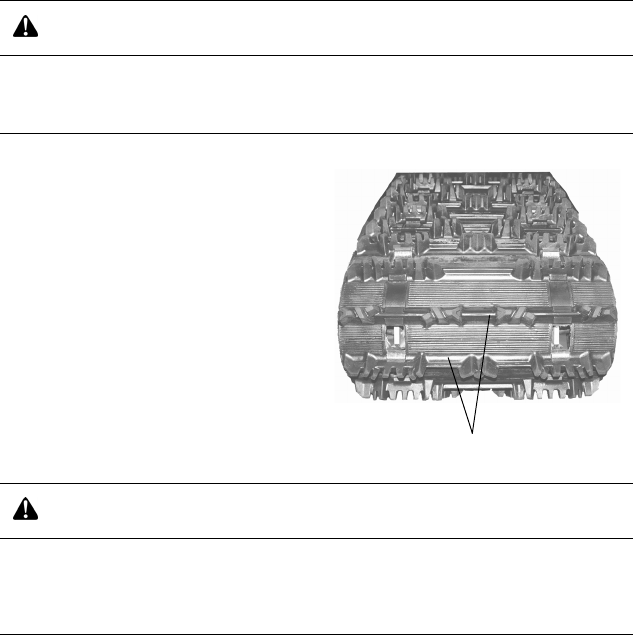

2. Rotate the track by hand to

check for damage.

3. Carefully examine the track

along the entire length of each

rod (✪). Bend the track to

check for breakage.

4. Replace the track if any rod

damage is found.

Track Lubrication

The slide rail needs snow for lubrication. Excessive wear indicates

insufficient lubrication. A new rail slide can cause faster heat build-up

in limited lubrication, resulting in excessive wear.

NOTE: If excessive rail slide wear occurs due to poor snow conditions,

additional wheel kits are available. See your dealer for more

information.

NOTE: Track damage or failure caused by operation on ice or under

other poor lubrication conditions will void the track warranty.

WARNING

Broken track rods can cause a rotating track to come off the machine, which

could cause serious injury or death. Never operate with a damaged track.

Never rotate a damaged track under power.

WARNING

Operating with insufficient lubrication between the rail slide and track guide

clips can cause track failure, loss of vehicle control and loss of braking ability,

which can result in serious injury or death. Avoid operating for extended peri-

ods on ice and other surfaces that have little or no snow for lubrication.

✪