MQ SP4030 SAW • OPERATION MANUAL — REV. #0 (01/22/09) — PAGE 47

MAINTENANCE

Removal and Replacement

To ensure correct blade shaft/wheel alignment, this

operation should be performed by and authorized service

center.

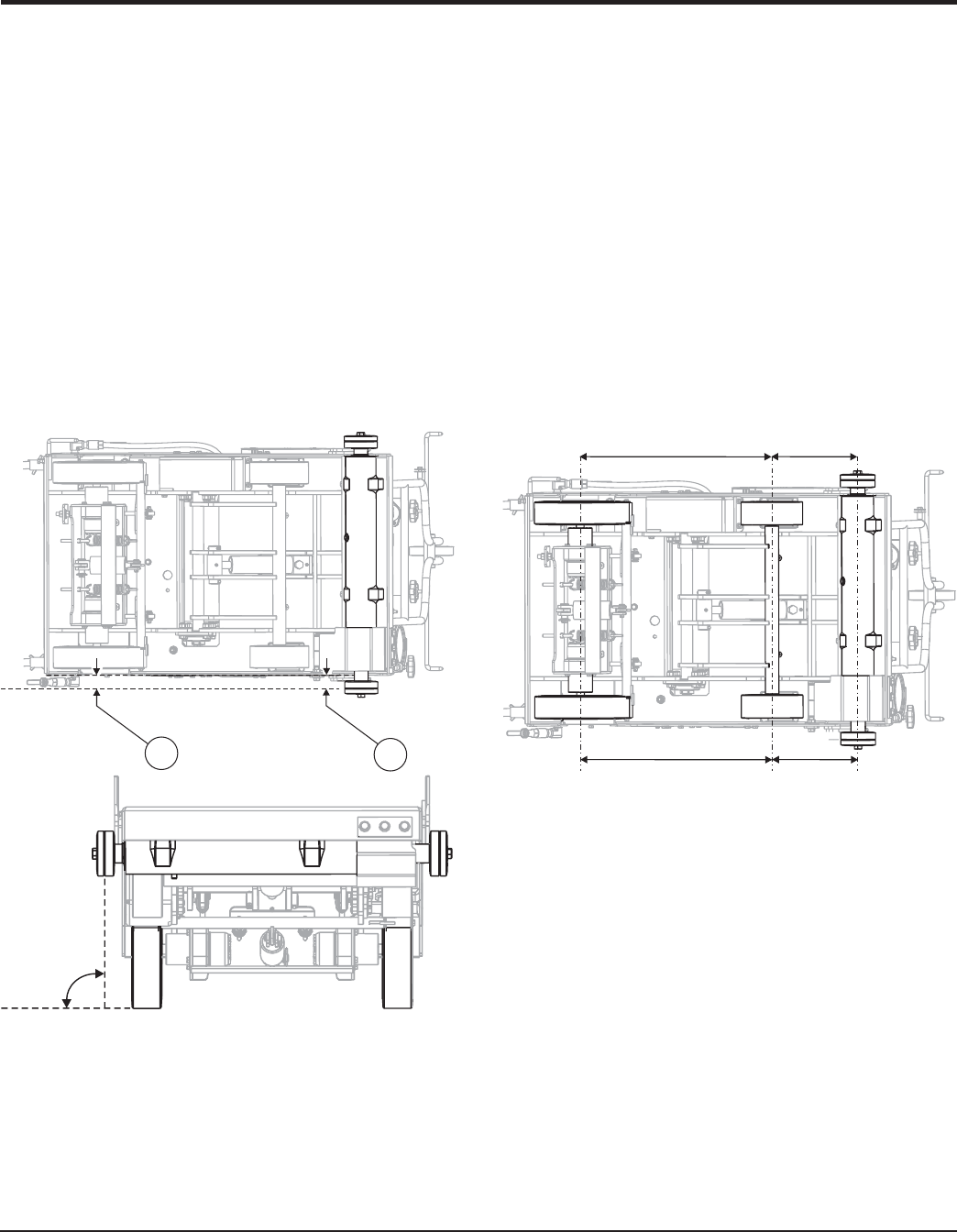

Blade Alignment

Maintaining proper blade and drive system alignment will

allow the saw to cut lines that are straight without much

effort. Therefore the blade shaft flanges MUST be

equadistant to the sides of the saw, (+/- .030"). See Figure

50 below where distance A must equal distance B.

The second requirement for the blade is that it MUST be

square to horizontal (90

o

to flat surface). See Figure 50.

A

B

90

o

Figure 50. Blade Alignment Requirements

A

A + .187”

X

X

Figure 51. Wheel Alignment Requirements

DRIVE SYSTEM ALIGNMENT

In addition to blade alignment, maintaining proper blade

and drive system alignment will allow the saw to cut lines

that are straight without much effort. Therefore the front

wheels and blade shaft axles MUST be at right angles to

the frame edge.

In Figure 51 you see the distance “A” on the right side is

shown as “A + .187"” which means that the distance

between centers of the front and rear drive axles are 3/16"

longer than on the opposite side. This will have the effect

of causing the saw to “steer” slightly to the left. After

becoming familar with the saws particular sawing

characteristics, the operator may wish to have this alignment

altered to fit his own preferences or to fit a particular

application.

Drive System Alignment Adjustment

The drive wheels are aligned by adjusting the entire rear

drive assembly.

1. Loosen the wheel mount assembly attachment bolts

just enough to move the wheel mount assembly. Do

not completely loosen the bolts.

2. Loosen and tighten the alignment jackscrew nuts to

move the wheel mount assembly, and thus the wheels,

in the appropriate direction to achieve the desired

alignment distance (Figure 51).