MQ SP4030 SAW • OPERATION MANUAL — REV. #0 (01/22/09) — PAGE 45

MAINTENANCE

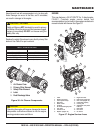

Belts and Pulleys

This saw uses a 6 groove 3V X 500 optibelt for its drive

belt system and a hydrostatic pump belt (AX-35).

V-Belt Tension

Ideal V-belt tension is the lowest tension at which the belt

will not slip under peak load conditions.

V-Belt Tensioning

The belt is tensioned via the turnbuckle and engine mount

assemblies.

1

2

3

1. Blade Shaft Drive Belt

2. Hydraulic Pump

3. Belt Tensioner Pulley

Figure 45. Belt Locations

CAUTION — Keep belts clean

Keep belts clean of foreign material that may cause

slippage. Never dress belts as this can cause premature

failure.

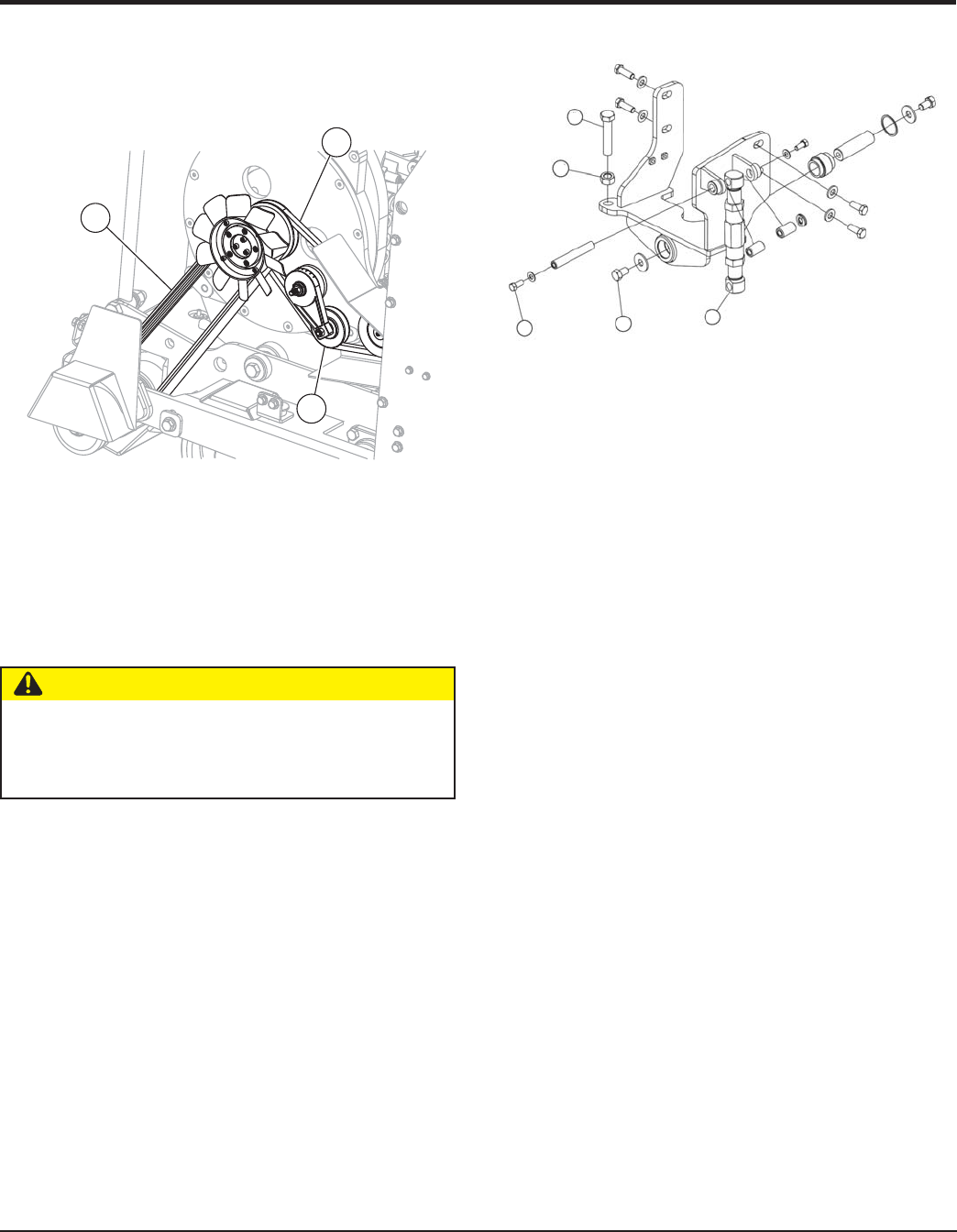

Figure 46.

1. Engine Mount Adjustment Screw

2. Engine Mount Adjustment Nut

3. Turnbuckle Pivot Screw

4. Engine Mount Pivot screw

5. Turnbuckle

1

2

3

4

5

V-Belt Replacement/Tensioning Procedure

1. Remove the Engine (Drive) Pulley Fan

2. Loosen Engine Mount Adjustment Nut (2)

3. Loosen Engine Mount Adjustment Screw (1)

4. Loosen Turnbuckle (5)

5. Pivot engine forward to further remove belt tension

the Eng Pivot Screw (4) is set at 50ft/lbs and should

permit engine rotation.

5. Remove/Replace V-Belt (#37577)

6. Rotate Engine back until V-Belt is taught

7. Tighten Turnbuckle until proper tension is achieved

8. Tighten Eng Mount Screw and Nut (1 &2)

9. Replace Engine (Drive) Pulley Fan