ENGINE <4D6> -

On-vehicle Service

11C-8

COMPRESSOR DRIVE BELT TENSION CHECK AND

ADJUSTMENT

11100100203

1. Check the tension by pulling or pushing at the centre

of the belt between pulleys with a force of 98 N as shown

in the figure. Measure drive belt deflection amount.

Standard value:

Items When

checked

When a

used belt is

installed

When a new

belt is

installed

Tension N 392 - 588 441 - 539 637 - 833

Deflection

(Reference

value) mm

9.2 - 12.0 9.8 - 11.2 7.0 - 8.6

2. If the tension is outside the standard value, adjust by

the following procedure.

(1) Loosen tensioner pulley fixing nut A.

(2) Adjust the belt tension using adjusting bolt B.

(3) Tighten fixing nut A.

Tightening torque: 25 Nm

(4) Check the belt frequency, tension or deflection, and

readjust if necessary.

Caution

Check after turning the crankshaft once or more

clockwise (right turn).

VALVE CLEARANCE CHECK AND

ADJUSTMENT

11100150130

1. Start the engine and allow it to warm up until the engine

coolant temperature reaches 80 to 95 _C.

2. Remove the timing belt upper cover.

3. Remove the rocker cover.

4. Remove the glow plug plate and all of the glow plugs.

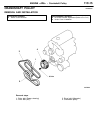

5. Turn the crankshaft clockwise to align the crankshaft pulley

timing mark and to set the No.1 cylinder or No.4 cylinder

to the compression top dead centre position.

NOTE

Aligning the camshaft sprocket timing mark will set the

No.1 cylinder to the compression top dead centre position.

If the crankshaft is turned one more full revolution from

this position, the No.4 cylinder will be set to the

compression top dead centre position.

A/C compressor

pulley

A

B

Crankshaft

pulley

Camshaft

sprocket

Timing

marks

Timing marks

Crankshaft

pulley