BASIC BRAKE SYSTEM -

On-vehicle Service

35A-13

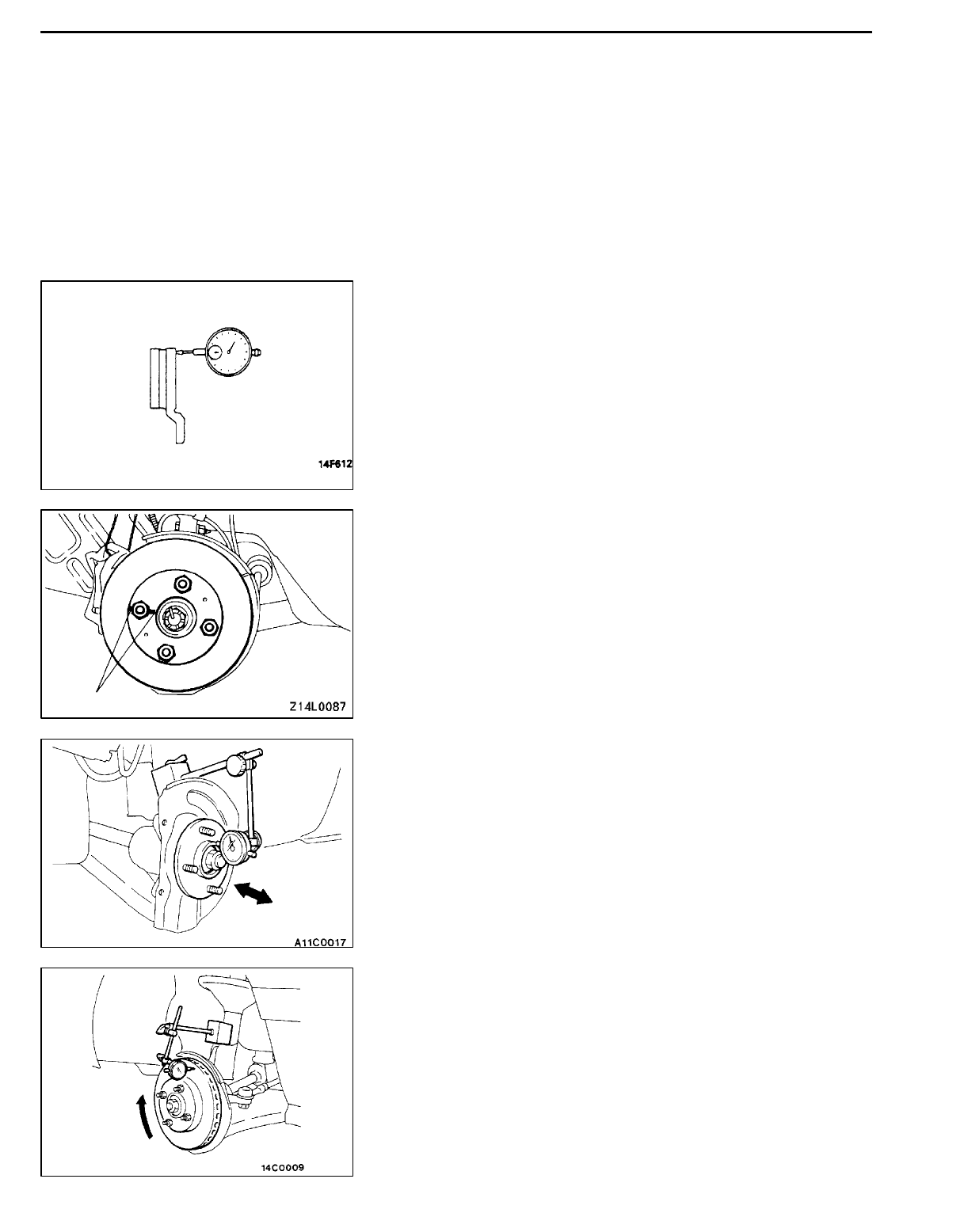

RUN-OUT CHECK

35100250010

1. Remove the caliper support; then raise the caliper

assembly upward and secure by using wire.

2. Inspect the disc surface for grooves, cracks and rust.

Clean the disc thoroughly and remove all rust.

3. Place a dial gauge approximately 5 mm from the outer

circumference of the brake disc, and measure the run-out

of the disc.

Limit:

0.06 mm or less <Front>

0.08 mm or less <Rear>

NOTE

Tighten the nuts in order to secure the disc to the hub.

RUN-OUT CORRECTION

35100180081

1. If the run-out of the brake disc is equivalent to or exceeds

the limit specification, change the phase of the disc and

hub, and then measure the run-out again.

(1) Before removing the brake disc, chalk both sides

of the wheel stud on the side at which run-out is

greatest.

(2) Remove the brake disc, and then place a dial gauge

as shown in the illustration; then move the hub in

the axial direction an d measure t he play.

Limit: 0.05 mm

If the play is equivalent to or exceeds the limit,

disassemble the hub knuckle and check each part.

(3) If the play does no t exceed the limit specification,

install the brake disc at a position 180_ away from

the chalk mark, and then check the run-out of the

brake disc once again.

2. If the run-out cannot be corrected by changing the phase

of the brake disc, replace the disc or turn rotor with on

the car type brake lathe (“MAD, DL-8700PF” or

equivalent).

Chalk mark