8.16

Section 8

Electrical System and Components

Inspection

Drive Pinion

Check and inspect the following areas:

a. The pinion teeth for abnormal wear or

damage.

b. The O.D. surface between the pinion and the

clutch mechanism for nicks, or irregularities

which could cause seal damage.

c. Check the drive clutch by holding the clutch

housing and rotating the pinion. Pinion should

rotate in one direction only.

Brushes and Springs

Inspect both the springs and brushes for wear, fatigue,

or damage. Measure the length of each brush. The

minimum length for each brush is 7.6 mm (.300 in.).

See Figure 8-24. Replace the brushes if they are

worn undersize, or their condition is questionable.

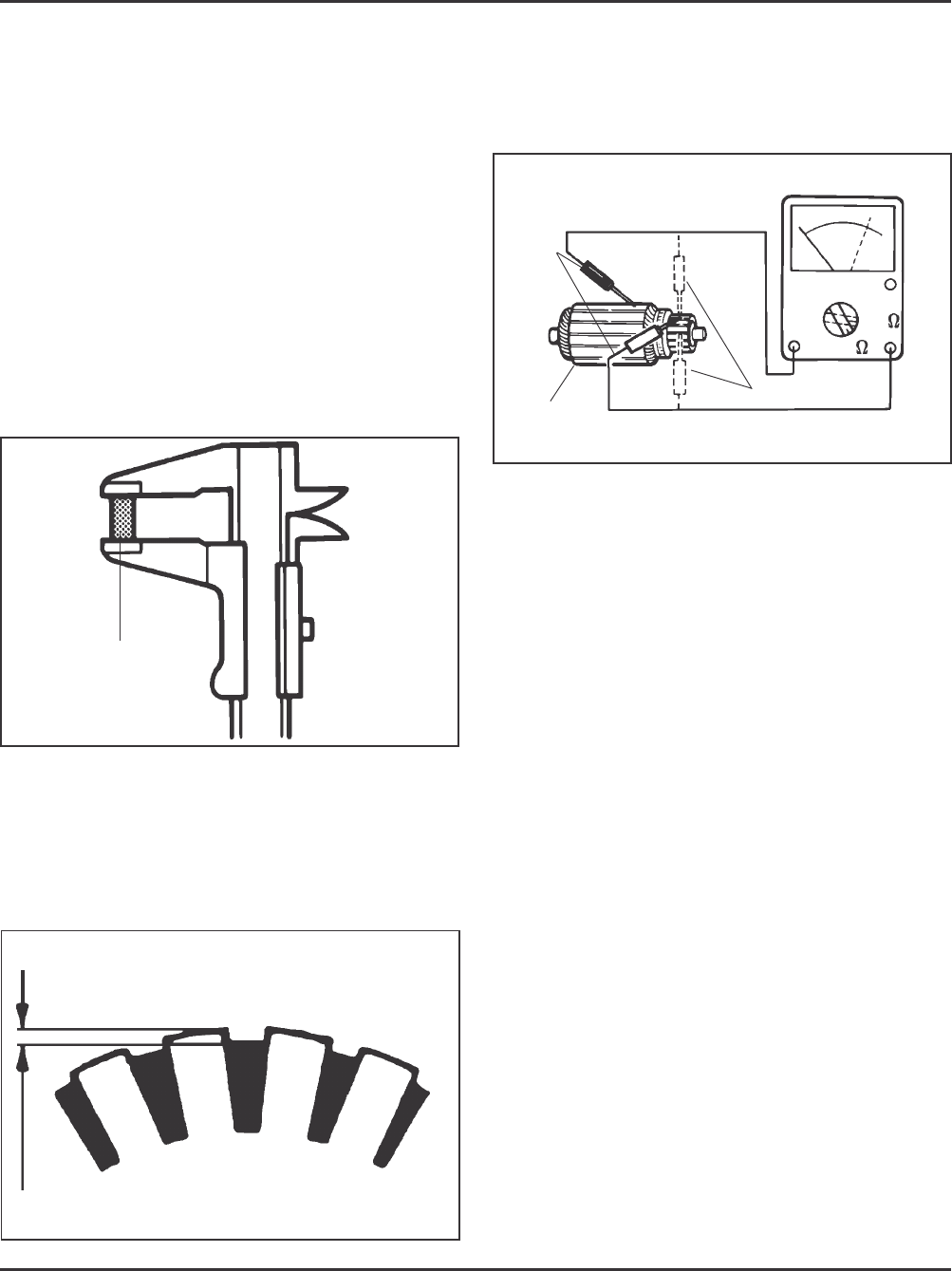

Figure 8-24. Checking Brushes.

Armature

1. Clean and inspect the commutator (outer surface).

The mica insulation of the commutator must be

lower than the O.D. surface (undercut) to ensure

proper operation of the commutator. See Figure

8-25.

Figure 8-25. Commutator Mica Inspection.

2. Use an ohmmeter set to the Rx1 scale. Touch the

probes between two different segments of the

commutator, and check for continuity. See Figure

8-26. Test all the segments. Continuity must exist

between all or the armature is bad.

Figure 8-26. Checking Armature.

3. Check for continuity between the armature coil

segments and the commutator segments. See

Figure 8-26. There should be no continuity. If

continuity exists between any two, the armature

is bad.

4. Check the armature windings/insulation for

shorting.

Shift Fork

Check that the shift fork is complete, and the pivot

and contact areas are not excessively worn, cracked

or broken.

Brush Replacement

The brushes and springs are serviced as a

set (4). Use Brush and Spring Kit, Kohler Part

No. 25 221 01-S, if replacement is necessary.

1. Perform steps 1-5 in “Starter Disassembly.”

Wear limit length:

1.6 mm (.300)

Commutator O.D.

Mica Insulation

Continuity Check

Armature

Coil

Insulation

Check