5.8

Section 5

Fuel System and Governor

Float Replacement

If symptoms described in the carburetor

troubleshooting guide indicate float level problems,

remove the carburetor from the engine to check and/or

replace the float. Use a Carburetor Overhaul Kit (see

page 5.10) if float replacement is necessary.

1. Remove the upper blower housing and air intake

components from the carburetor, as described in

Section 4.

2. Disconnect the fuel inlet line from the carburetor.

3. Disconnect the governor, choke and throttle

linkages from the carburetor.

4. Disconnect the lead wires from the carburetor

solenoid.

5. Gently lift up on the lower blower housing directly

above the carburetor and slide the carburetor off

the mounting studs. Remove the fuel shut-off

solenoid and drain any remaining fuel into a safe

container. Remove the bowl from the carburetor

body.

7. Pull the float hinge pin and remove the float, with

the inlet needle attached, to inspect these parts

and the needle seat. If dirty, blow out with

compressed air. Replace float components as

needed with kit.

8. Using new bowl gaskets, reinstall and tighten the

bowl with the fuel shut-off solenoid. Tighten to

5.1-6.2 N·m (45-55 in. lb.).

9. Reinstall carburetor to engine, reconnecting the

fuel line, control linkages and solenoid leads.

Reinstall the air intake components, and upper

blower housing assembly. Retest operation.

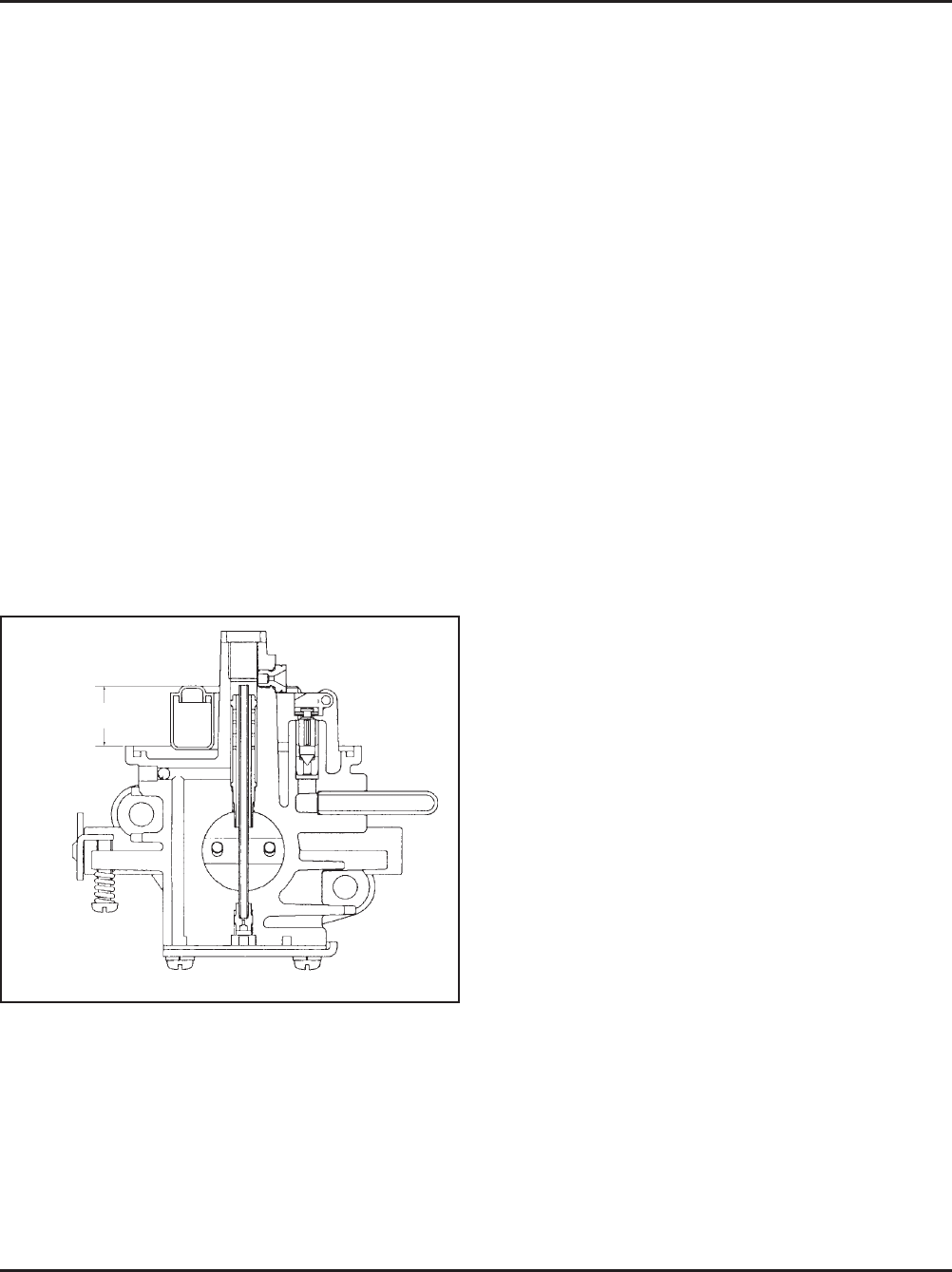

Disassembly

Use the following procedure to disassemble the

carburetor after removing it from the engine. Refer to

Figure 5-6 for identification of the component parts.

1. Remove the fuel shut-off solenoid assembly, then

remove the fuel bowl and bowl gasket.

2. Pull the float hinge pin. Remove float with inlet

needle attached.

3. Remove the set screws holding the throttle plate

to the throttle shaft. Check for any burrs on the

shaft and remove them. Pull the throttle shaft from

the carburetor body.

5. Remove the set screws securing the choke plate

to the choke shaft assembly. Check for any burrs

on the shaft and remove them. Pull the choke

shaft assembly out of the carburetor body.

Disassemble self-relieving parts from shaft as

needed.

6. Remove the three screws holding the passage

cover to the body. Remove the cover and gasket.

7. Remove the slow speed adjusting needle and

spring. Except for the slow jet nozzle, main jet,

and emulsion tubes, which are considered

non-serviceable, the carburetor is now completely

disassembled and ready for thorough inspection

and cleaning.

16.5 mm

(0.65 in.)

Turn

Carburetor

Upside Down

Figure 5-5. Proper Float Level.

6. Turn the carburetor upside down and check the

level of the float, as shown in Figure 5-5. With the

float needle valve fully seated, 16.5 mm (.65 in.)

should be measured from the body to the float as

indicated. Don’t attempt to adjust by bending the

tab. Install a new float if level is wrong.