11.11

Section 11

Reassembly

11

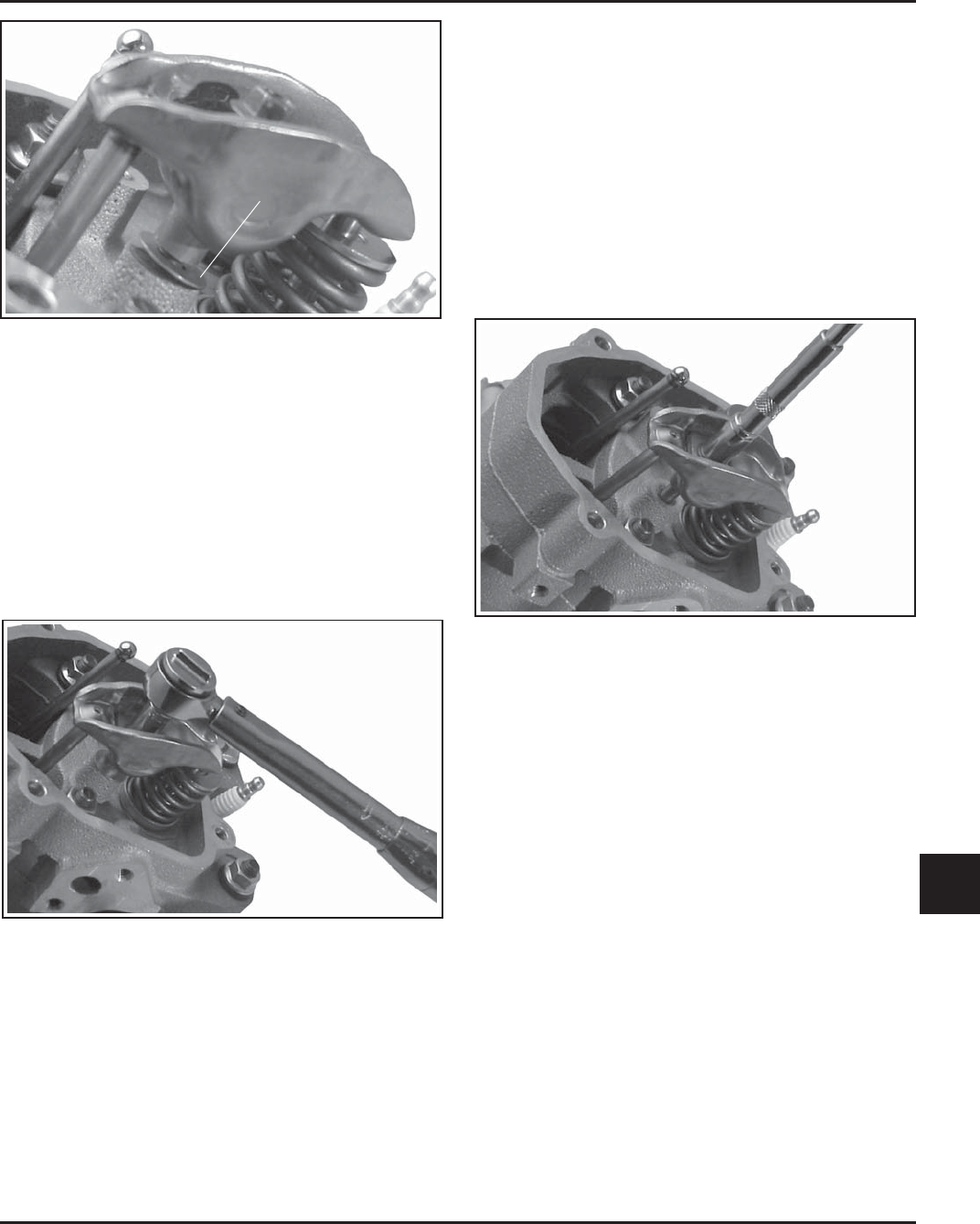

Figure 11-30. Installing Shim(s).

14. Reassemble the rocker arm and pivot assembly

to the head and seat the push rod. See Figure

11-30. Torque the fastener; 11.3 N·m (100 in. lb.)

for a hex. flange screw, or 17.3 N·m (153 in. lb.)

for a lock nut. See Figure 11-31.

15. Hold down the push rod end of the rocker arm

(step 9). Using a feeler gauge, check that there is

0.03-0.3 mm (0.001-0.010 in.) clearance between

the rocker arm and the end of the valve. See

Figure 11-38.

Figure 11-31. Torquing Rocker Arm.

16. Repeat the procedure for the other valve.

17. As viewed from the PTO end, rotate the

crankshaft 3/4 turn (270°) counterclockwise

and align the crankshaft keyway with the #2

cylinder, which now puts that cylinder at TDC

on the compression stroke. Repeat steps 3-15

for the #2 head. Do not interchange parts from

one cylinder head to the other.

Valve Lash Setting Procedure Not Using a Dial

Indicator (Adjustable Valve Train)

The following procedure may be used as an alternate

method for setting the valve lash. Although not as

precise as using the dial indicator method, a valve lash

setting within 0.001 in. - 0.003 in. of the previous

procedure is possible. It is imperative that the lifters be

completely bled down (See ‘‘Install Hydraulic Lifters’’)

so they can be compressed by hand.

8. Assemble the rocker arms and rocker arm pivots

onto the cylinder head. Do not move or rotate

the crankshaft.

Figure 11-32. Mounting the Rocker Arm onto the

Cylinder Head.

9. Manually depress the push rod end of the rocker

arm to the bottom/limit of the lifter plunger travel.

The opposite end of the rocker arm should be

directly over the end of the valve. Hold in this

position for the next two steps (10 and 11), do

not release. See Figure 11-33.

NOTE: If at any time during the setting

procedure the lifter plunger cannot be

depressed by hand or is very hard to

move, STOP! Remove the lifter, re-bleed

and reinstall.

Shim

5/04