6 308–287

Operation

Pressure Relief Procedure

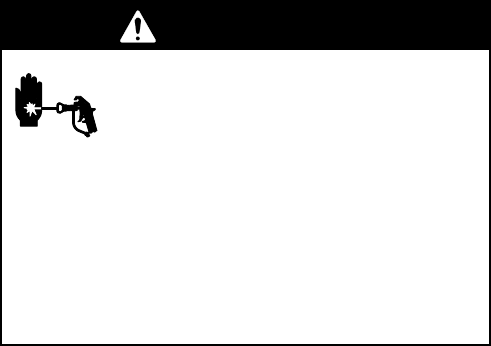

WARNING

INJECTION

HAZARD

Fluid under high pressure can be in

-

jected through the skin and cause

serious injury

. T

o reduce the risk of an

injury from injection, splashing fluid, or moving

parts, follow the

Pressure Relief Procedure

whenever you:

D

are instructed to relieve the pressure,

D

stop operating,

D

or check or service any of the system equip

-

ment.

1. T

urn of

f the air supply to the meter

.

2.

Allow air to exhaust out of the exhaust air port.

3. T

urn of

f the fluid supply to the meter

.

4.

Shut of

f all electrical power to the fluid system or

air system.

5.

Follow the Pressure Relief Procedure for your fluid

system dispensing device.

System Operating Checklist

Check

the following list daily

, before starting to operate

the system, to help ensure you of safe, ef

ficient opera

-

tion.

D

Be sure all operators are properly trained and

qualified to safely operate your system.

D

Be sure all operators are trained how to properly

and completely relieve system pressure according

to the

Pressure Relief Procedure

, at left.

D

Be sure the system is thoroughly grounded. See

FIRE, EXPLOSION, AND ELECTRIC SHOCK

HAZARD

, page 2, and

Check the Electrical

Grounding

, page 5.

D

Be sure the operator and all persons entering the

installation site are properly grounded by wearing

shoes with conductive soles or personal grounding

straps.

D

Be sure ventilation fans are operating properly

.

Operation

Operate the flow meter between 20–50 psi (140–350

kPa, 1.4–3.5 bar) air inlet pressure. The yellow flow

meter indicator light will come on when the proper air

pressure is supplied. The green flow meter indicator

light will blink on and of

f when the fluid is flowing.