19

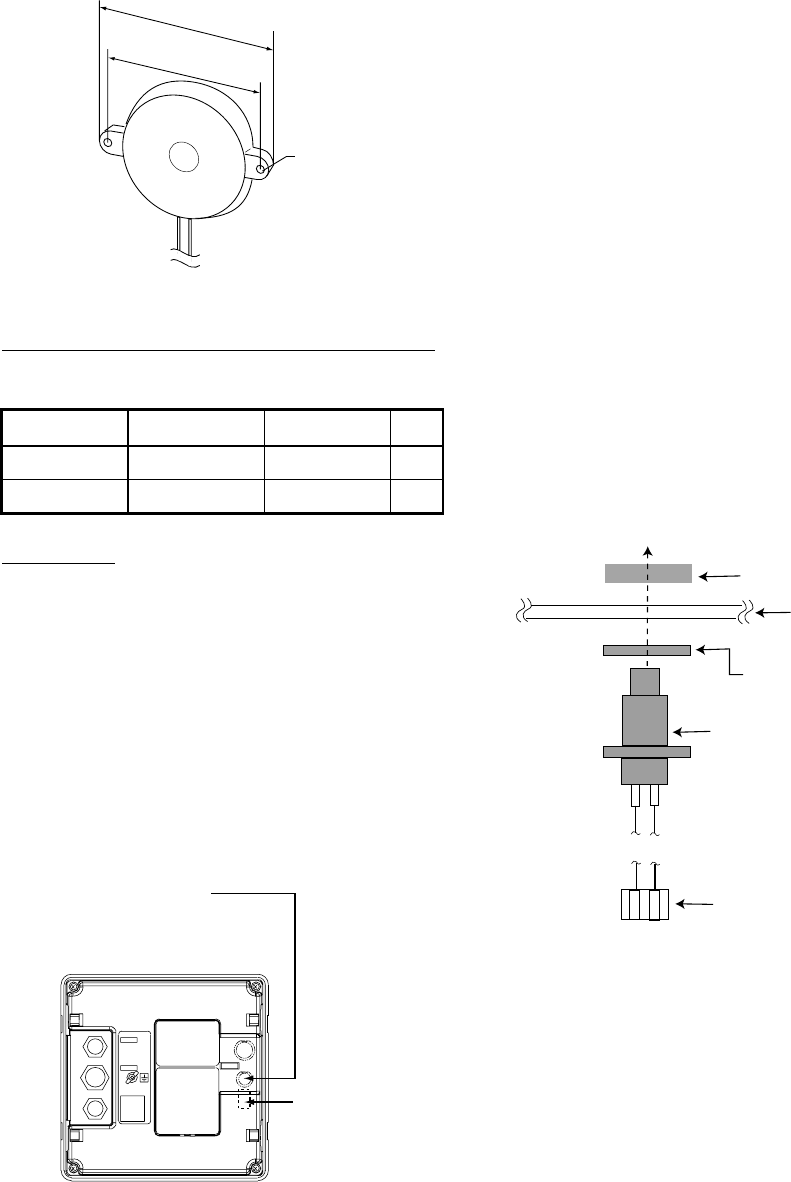

Connection of external buzzer (option)

The external buzzer provides an aural alarm

when the guard zone is violated.

60 mm

50 mm

2-φ3.5

Figure 3-6 External buzzer

External buzzer installation kit contents

Type: OP03-168, Code No.: 008-462-790

Name Type Code no. Qty

MJ-XH conn. 03-2022 (2-3P) 008-463-540 1

Buzzer assy. 80-0641 008-462-800 1

Procedure

1. Unfasten screws and three connector

nuts (NMEA, POWER, DJ-1) from the

rear cover to detach it.

2. Place the rear cover on a workbench,

out side up.

3. Using a slotted-head screwdriver and

hammer, punch out the “hole cover”

from the location shown in the figure

below. Remove burrs from the hole with

a fine file or sandpaper.

Remove hole cover with

slotted-head screwdriver and

hammer. Remove burrs from hole

with fine file or sandpaper.

J6 located at right

side of shield case

under the rear panel.

Figure 3-7 Display unit, rear view

4. Set the gasket to the MJ connector and

insert the connector in the hole made at

step 3.

5. Fasten the connector with the connector

nut (torque: 0.75-0.78 N•m). Tighten the

connector nut by hand until you feel

slight resistance and then turn it an

additional 45

°

with a box wrench.

6. Plug in the XH connector at the end of

the MJ connector into J6 on the DU

Board. (See Figure 3-7 for location.)

7. Insert NMEA, POWER and DJ-1

connectors. Tighten connector nut by

hand until you feel slight resistance and

then turn it an additional 90

°

(NMEA and

POWER) or

45

°

(DJ-1) with a box

wrench.

8. Reattach the cover. (Be sure the gasket

is correctly positioned and there is no

foreign material in the unit before closing

the cover.)

9. Fasten the buzzer within 1 m of the

display unit with two tapping screws

(3X15 or 3X20, local supply).

10. Attach the connector from the external

buzzer to the MJ connector.

Connector nut

Rear cover of

display unit

Gasket

MJ connector

XH connector

(to J6 on DU Board)

Figure 3-8 How to assemble

MJ-XH connector assembly

Note:

Assemble the MJ-XH connector

assembly exactly as shown in Figure

3-8, otherwise watertight integrity

cannot be guaranteed. Further,

watertight integrity cannot be

guaranteed if foreign material (dust,

etc.) is on the connector when it is

assembled.