ease the holder out of the alternator. Inspect

the brushes and if worn below the specified

minimum length, they must be renewed.

7 Disconnect the brush leads by unsoldering

or carefully cutting them.

8 When soldering the new brush leads, do

not allow solder to run down them or their

flexibility will be ruined.

9 When inspecting or renewing brushes,

check the surface of the slip rings. Clean them

with solvent or if they are very discoloured,

use very fine glasspaper.

6 Voltage regulator

1 This is of integral type and is part of the

brushholder assembly.

2 No provision is made for adjustment or

overhaul.

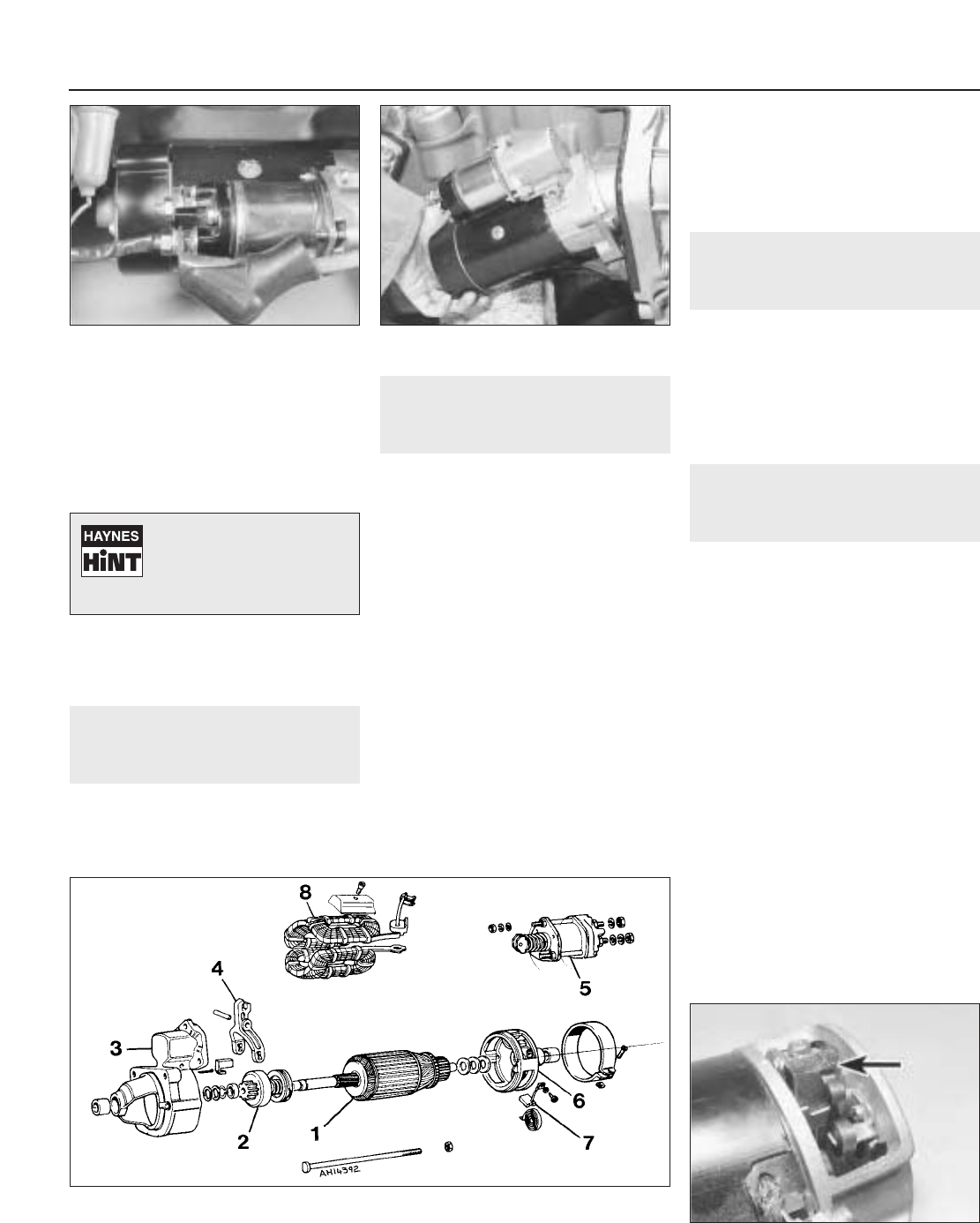

7 Starter motor -

description and testing

2

1 The starter motor may be one of two

different makes. Both are of pre-engaged

type.

2 This type of starter motor incorporates a

solenoid mounted on top of the starter motor

body. When the ignition switch is operated,

the solenoid moves the starter drive pinion,

through the medium of the shift lever, into

engagement with the flywheel starter ring

gear. As the solenoid reaches the end of its

stroke, and with the pinion by now partially

engaged with the flywheel ring gear, the main

fixed and moving contacts close and engage

the starter motor to rotate the engine.

3 This pre-engagement of the starter drive

does much to reduce the wear on the flywheel

ring gear associated with inertia type starter

motors.

4 If the starter fails, some fault-finding can be

done with it still on the car. Check the ignition

warning light comes on, and does not go out

when the starter is switched on. If it goes out,

the fault is probably in the battery. If it stays

bright, get an assistant to work the switch,

whilst listening to the starter. Listen to find out

if the solenoid clicks into position. If it does

not, pull off the solenoid wire, and check it

with a test bulb. If the wire is live when the key

is turned, but the solenoid does not move,

take off the starter and remove it to the bench

for overhaul.

8 Starter motor -

removal and refitting

1

1 Disconnect the battery negative lead.

2 Disconnect the lead from the starter motor

(photo).

3 Unscrew the fixing bolts and withdraw the

starter motor, downwards on 1116 cc and

1301 cc models (photo).

4 Refitting is a reversal of the removal

procedure.

9 Starter motor - overhaul

3

1 As with the alternator, the operations

should normally be limited to renewal of the

brushes. If the unit has covered a high

mileage it will usually be more economical to

purchase a new or factory-reconditioned one

rather than renew several components of the

original unit.

2 Owing to the possibility that a fault can

develop in the starter motor solenoid or drive

assembly, full dismantling procedures are

given later in this Section.

Brush - renewal

3 Slide off the cover band.

4 Using a hooked piece of wire, pull up the

springs so that the brushes can be withdrawn

and their lengths checked for wear. If they

have worn below the specified minimum

length, renew them by extracting the brush

lead connecting screws (photo).

Solenoid

5 Disconnect the field connecting wire from

the solenoid.

6 Unscrew the bolts which hold the solenoid

to the end-frame.

7 Unscrew the yoke tie-rod nuts.

9•4 Electrical system

9.4 Starter motor brush partly withdrawn

8.2 Starter motor connections 8.3 Removing starter motor

Fig. 9.2 Exploded view of typical starter motor (Sec 9)

1 Armature

2 Drive pinion/clutch

3 Drive end bracket

4 Shift lever

5 Solenoid

6 Brush endplate

7 Brush

8 Field windings

Gripping the brush leads with

a pair of pliers to act as a

heat sink will prevent heat

transfer to the internal

components of the alternator.