PART B:

CARBURETTOR MODELS

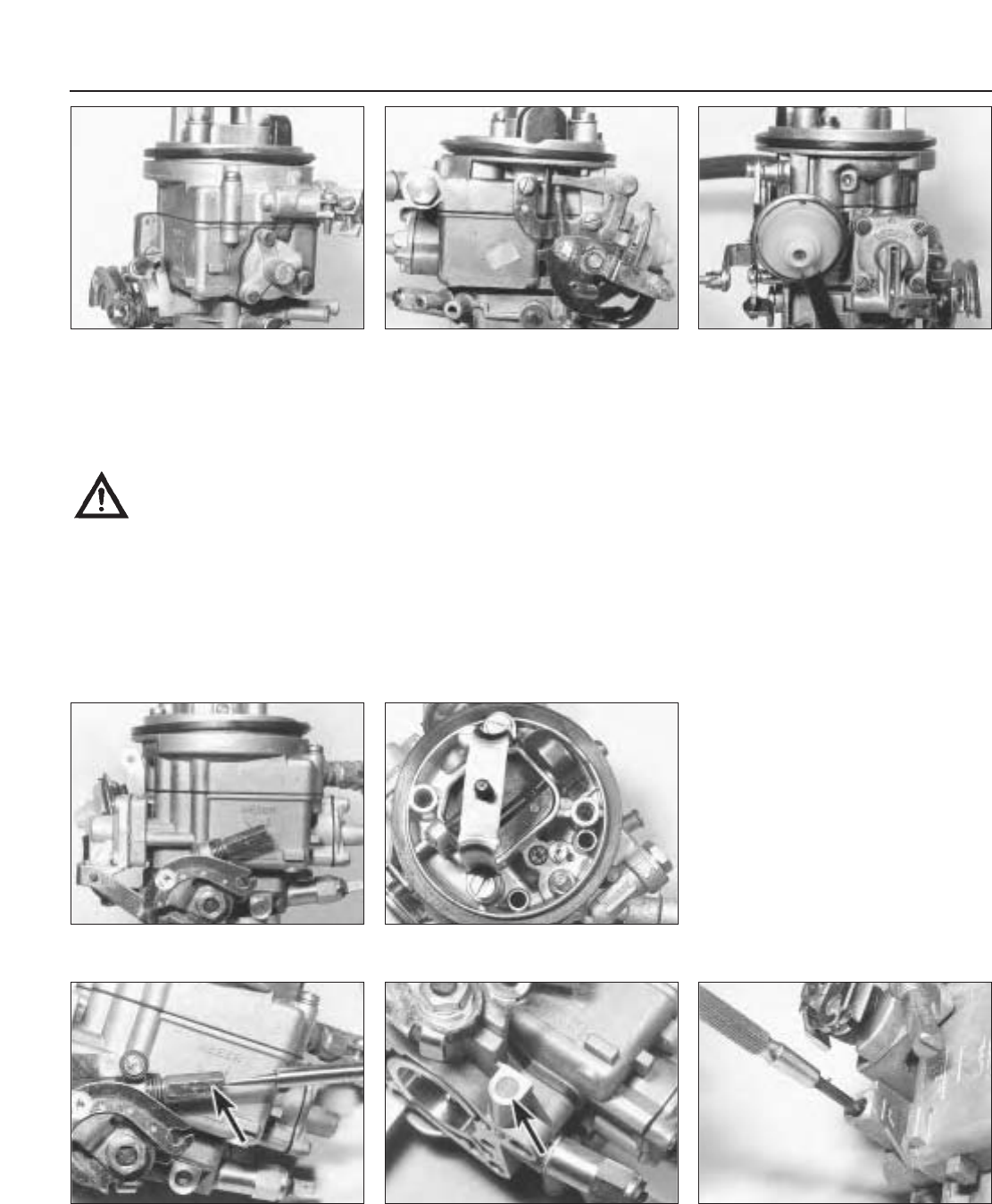

Carburettor (Weber 32 TLF) -

description

Warning: Refer to the beginning

of this Section before starting

any work.

1 This carburettor is used on the 999 cc

engine and is of the single venturi

downdraught type, with a manually-operated

choke (cold start).

2 The unit incorporates an automatic

anti-flooding device, a full power valve and an

accelerator pump (photos).

3 The throttle valve block, although

incorporating coolant hose stubs, is not in fact

coolant-heated.

4 A solenoid-operated idle cut-off valve is

fitted to prevent running-on (dieseling) when

the ignition is switched off.

Carburettor (Weber 32 TLF) -

idle speed and mixture

adjustment ¢

5 If the car is not equipped with a rev counter,

connect one in accordance with the

manufacturer’s instructions.

6 Have the engine at normal operating

temperature and idling. Turn the idle speed

screw on the carburettor until the speed

matches that specified (photo).

7 The idle mixture is set in production, and

the adjustment screw is sealed with a

tamperproof cap. If, however, the idling is not

smooth or the engine or carburettor have

been extensively overhauled, the mixture may

require adjusting.

8 Prise out the tamperproof plug and connect

an exhaust gas analyser to the car in

accordance with the instrument

manufacturer’s instructions (photo).

9 With the engine at normal operating

temperature and idling at the specified speed,

turn the mixture screw until the CO

percentage is within the specified tolerance

(photo).

10 If an exhaust gas analyser is not available,

turn the mixture screw anti-clockwise to

obtain maximum idle speed and then turn it

clockwise until the speed just starts to drop.

Re-adjust the idle speed screw to bring the

idle speed to the specified level.

11 Switch off the engine and remove the test

instruments. It is advisable to fit a new

tamperproof cap to the mixture screw if it is

intended to take the vehicle overseas. This is

required to meet legislation in certain

countries.

Carburettor (Weber 32 TLF)

- removal and refitting ™

12 Remove the air cleaner.

13 Release the clips and disconnect the fuel

hoses from the carburettor. Take extreme

care that fuel spillage is contained and that

there are no naked flames in the vicinity of the

work area. Do not smoke.

14 Disconnect the distributor vacuum hose

from the carburettor.

13•62 Supplement: Revisions and information on later models

9B.9 Mixture adjustment - Weber 32 TLF

carburettor

9B.8 Weber 32 TLF 4/250 carburettor

mixture screw location under tamperproof

plug (arrowed)

9B.6 Weber 32 TLF 4/250 carburettor idle

speed screw (arrowed)

9B.2E Weber 32 TLF 4/250 carburettor

from above

9B.2D Weber 32 TLF 4/250 carburettor

from throttle linkage side

9B.2C Weber 32 TLF 4/250 carburettor

from accelerator pump side

9B.2B Weber 32 TLF 4/250 carburettor

from choke linkage side

9B.2A Weber 32 TLF 4/250 carburettor

from anti-run-on solenoid valve side