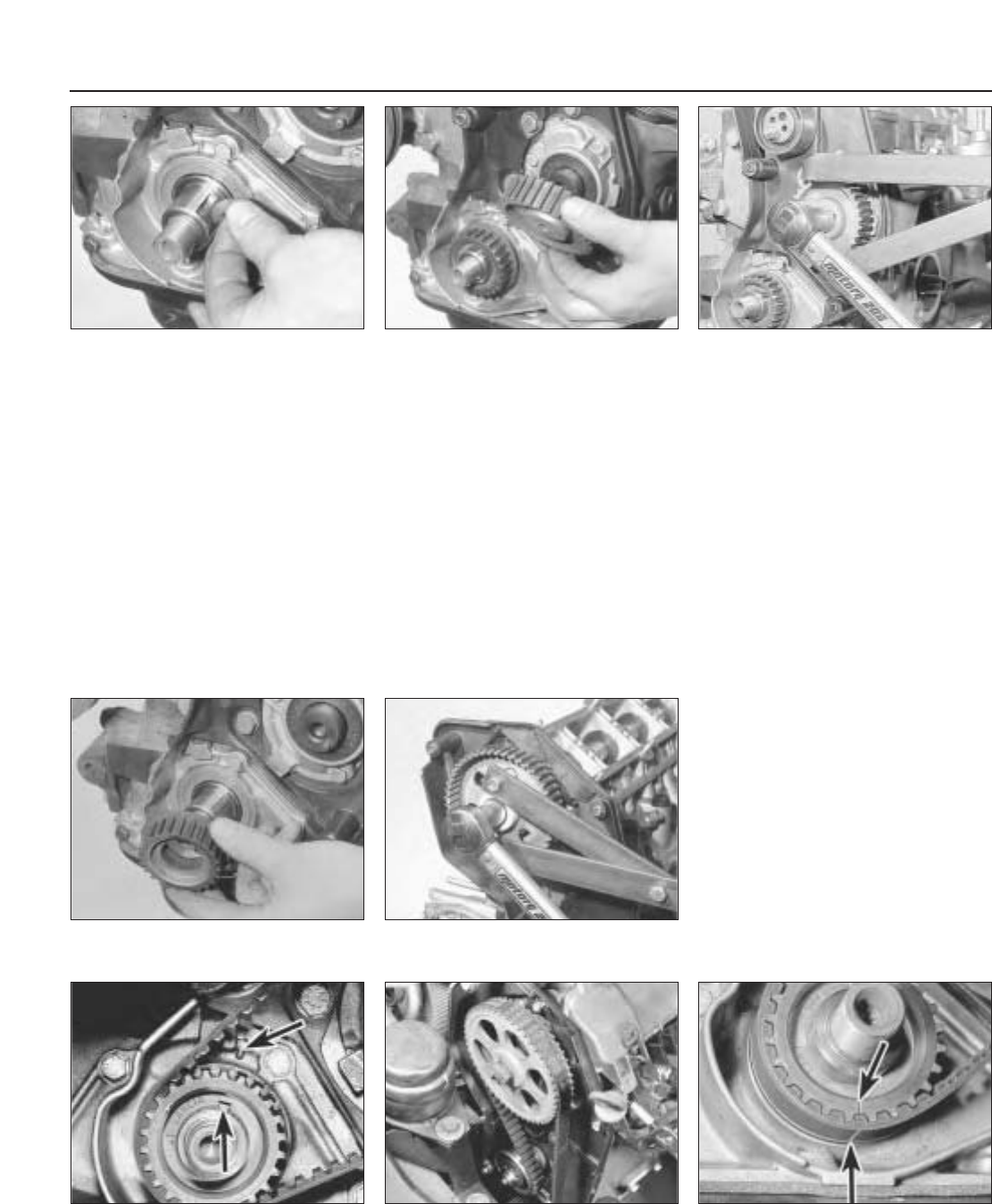

crankshaft after the pulley securing nut has

been removed. Recover the Woodruff key

from the end of the crankshaft if it is loose

(photo).

44 To remove the auxiliary shaft sprocket, a

suitable tool must be used to hold the

sprocket stationary as the securing bolt is

loosened (the bolt is extremely tight). In the

workshop, a “scissors” style tool was

improvised, using two pieces of steel bar

joined together by a pivot bolt, with their ends

bent through a right-angle to engage securely

between the teeth on the sprocket - see photo

7B.46.

45 Unscrew the sprocket bolt, and recover

the washer, then withdraw the sprocket from

the end of the auxiliary shaft (photo). If the

sprocket is tight, carefully lever it from the

shaft using two screwdrivers.

46 Refit the auxiliary shaft sprocket, making

sure that the lug on the end of the shaft

engages with the hole in the sprocket, then

tighten the securing bolt to the specified

torque (ensure that the washer is in place

under the bolt head). Prevent the sprocket

from turning as during removal (photo).

47 Where applicable, refit the Woodruff key

to the end of the crankshaft, then refit the

crankshaft sprocket with the flanged side

against the oil seal housing (photo).

48 Refit the camshaft sprocket to the end of

the camshaft, making sure that the lug on the

end of the shaft engages with the hole in the

sprocket, then refit the thrust washer, plain

washer, and bolt, and tighten the bolt to the

specified torque. Prevent the camshaft from

turning as during removal (photo).

49 Refit the belt tensioner pulley assembly,

ensuring that the washer is in place under the

securing nut, but do not fully tighten the nut at

this stage.

50 Before refitting the new timing belt into

position, first ensure that the crankshaft and

camshaft sprocket timing marks are still

aligned as described in paragraph 30 (photo).

51 If the new timing belt has two timing marks

on its outer face they must align with the

corresponding marks on the crankshaft and

camshaft sprockets. Do not distort or bend the

belt any more than is necessary during its

fitting or its structural fibres may be damaged.

52 Refit the belt around the sprockets and

the tensioner pulley, starting at the crankshaft

sprocket. One of the timing index marks must

align with the scribed mark on the lower edge

of the crankshaft sprocket (opposite the

Woodruff key) whilst the second mark must

align with the timing marks of the camshaft

and rear timing belt cover (photos).

53 With the belt fitted over the sprockets and

correctly aligned, temporarily refit the

crankshaft pulley nut (tightening it to its full

torque wrench setting) and then adjust the

timing belt tension.

Approximate setting

54 The timing belt tension can be checked

approximately by twisting it between the

13•40 Supplement: Revisions and information on later models

7B.52B Timing belt mark aligned with

scribed mark on crankshaft sprocket

(arrowed)

7B.52A Timing belt refitted over the

sprockets and tensioner

7B.50 Crankshaft at TDC with key and

timing mark aligned (arrowed)

7B.48 Tightening the crankshaft sprocket

bolt

7B.47 Refitting the crankshaft sprocket

7B.46 Tightening the auxiliary shaft

sprocket bolt

7B.45 Withdrawing the auxiliary shaft

sprocket

7B.43 Remove the crankshaft Woodruff

key if it is loose