6 On 999, 1108 and 1372 cc engines, the

distributor is driven from the rear end of the

camshaft.

7 On the 1116 and 1299/1301 cc engines, the

distributor is driven from an extension of the

oil pump driveshaft which is geared to the

auxiliary shaft.

8 The distributor contains a reluctor mounted

on its shaft, and a magnet and stator fixed to

the baseplate.

9 Ignition advance is controlled in the

conventional way mechanically by centrifugal

weights and a diaphragm unit for vacuum

advance.

10 Instead of the conventional method of

interrupting the low tension circuit to generate

high tension voltage in the coil by means of a

mechanical contact breaker, when the

electronic ignition is switched on, the

switching of the transistors in the electronic

control unit (ECU) prevents current flow in the

coil primary windings.

11 Once the crankshaft rotates, the reluctor

moves through the magnetic field created by

the stator and when the reluctor teeth are in

alignment with the stator projections a small

AC voltage is created. The ECU amplifies this

voltage and applies it to switch the transistors

and so provide an earth path for the primary

circuit.

12 As the reluctor teeth move out of

alignment with the stator projections the AC

voltage changes, the transistors in the ECU

are switched again to interrupt the primary

circuit earth path. This causes a high voltage

to be induced in the secondary winding.

Distributor

(breakerless type) -

removal and refitting #

13 Removal of the distributor on the 903,

1116, 1299 and 1301 cc engines is as

described in Chapter 4, Section 6.

14 On 999, 1108 and 1372 cc engines, mark

the position of the distributor clamp plate in

relation to the cylinder head surface.

15 Unclip the distributor cap and move it to

one side with the HT leads attached.

16 Disconnect the LT lead plug and, where

applicable, the vacuum hose (photo).

17 Unscrew the distributor fixing nuts and

withdraw the unit.

18 The distributor drive is by means of an

offset dog no special procedure is required to

refit it. Providing the dog engages in its slot

and the distributor body is turned to align the

marks made before removal, the timing will

automatically be correct.

19 If a new distributor is being fitted (body

unmarked), set No. 4 piston at TDC (0º) by

turning the crankshaft pulley bolt until the

timing marks on the crankshaft pulley and

engine front cover are in alignment.

20 Align the drive dog and fit the distributor

then turn the distributor body until the contact

end of the rotor is aligned with the arrow on

the distributor dust shield.

21 Tighten the distributor clamp nuts. Refit the

cap and disconnected components and then

check ignition timing using a stroboscope.

Distributor (breakerless

type) - overhaul #

22 It is recommended that a worn out or

faulty distributor is renewed. However,

individual components such as the cap, rotor,

reluctor, magnet/stator/baseplate assembly,

vacuum diaphragm unit, and drive gear or dog

are available separately.

Breakerless

ignition system

components - testing ™

23 A voltmeter and an ohmmeter will be

required for this work.

Primary circuit voltage

24 Turn on the ignition, and using a voltmeter

check the voltage at the ignition coil LT

terminals. Any deviation from battery voltage

will indicate a faulty connection, or if these are

satisfactory, then the coil is unserviceable.

Magnetic impulse generator winding

25 Remove the distributor and ECU and

disconnect their connecting leads.

26 Connect an ohmmeter to the impulse

generator terminals and note the reading. The

resistance should be as given in the Specifi-

cations at the beginning of this Chapter.

27 Now check between one of the impulse

generator terminals and the metal body of the

distributor. Infinity should be indicated on the

ohmmeter. If it is not, renew the impulse

generator carrier plate. Note: When carrying out

this test it is imperative that the connections are

remade as originally observed. Also ensure that

there is no possibility of the ECU supply (red)

cable and earth cable making contact in service.

Ignition coil winding resistance

28 Check the resistance using an ohmmeter

between the coil LT terminals. Refer to the

Specifications for the expected coil resistance.

29 Check the resistance between the LT lead

socket on the coil and each of the LT

terminals. Refer to the Specifications for the

expected coil resistance.

30 The rotor arm resistance should be

approximately 5000 ohms.

Microplex ignition system -

description

31 This system is fitted to the 1301 and

1372 cc Turbo ie models, and comprises the

following components.

Electro-magnetic sensors

32 Two sensors are used to pick up engine

speed and TDC position directly from the

crankshaft.

Pressure and vacuum sensor

33 This converts inlet manifold vacuum

pressure into an electrical signal for use by

the electronic control unit (ECU).

Anti-knock sensor

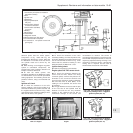

34 This converts “pinking” detonations which

occur within the combustion chambers into

an electrical signal for use by the ECU (photo).

Electronic Control Unit (ECU)

35 This computes the optimum ignition

advance angle from the sensor signals

received, and controls the action of the

ignition unit (photo).

13•86 Supplement: Revisions and information on later models

Fig. 13.72 Rotor aligned with arrow on

distributor dust shield - 999 and 1108 cc

engines (Sec 10)

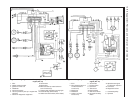

1 ECU

2 Ignition coil

3 Distributor

4 Vacuum advance

unit

5 Pick-up filter with

calibrated opening

for atmospheric

pressure

Fig. 13.71 Location of electronic ignition

components on early models with

breakerless ignition (Sec 10)

10.16 Distributor LT lead connecting plug