control unit is functioning, if the tachometer

does not register, renew the ignition control

unit.

16 If a replacement carburettor is to be fitted,

only fit the Solex assembly including the

control module, even if a Weber was originally

fitted.

12 Carburettor

(Weber 32 ICEV 51/250) -

servicing and adjustment

4

1 This carburettor, fitted to 1116 cc engines,

is very similar to the unit described in Sec-

tion 9.

2 The fast idle adjustment procedure is

identical, but note that dimension (A) (Fig.

3.12) should be between 0.85 and 0.90 mm

(0.033 and 0.035 in).

3 The choke valve plate gap (Y) (Fig. 3.13)

should be between 5.5 and 6.5 mm (0.22 and

0.26 in) and if adjustment is required, bend

the stop on the control lever.

13 Carburettor

(Solex C32 DISA 12) -

servicing and adjustment

4

1 This carburettor is an alternative to the

Weber fitted to 1116 cc engines.

2 The adjustments described in Section 9

apply.

14 Carburettor

(Weber 30/32 DMTR 90/250)

- servicing and adjustment

4

1 The carburettor top cover with float may be

removed without the need to withdraw the

carburettor from the manifold. The other

adjustments described in this Section will

require removal of the carburettor.

2 Extract the top cover fixing screws and lift

away the top cover with float. Access to the

fuel inlet needle valve is as described in

Section 9 paragraphs 4 and 5.

Float adjustment

3 Hold the cover vertically so that the floats

hang down under their own weight. Measure

the distance between the float and the surface

of the gasket on the top cover. This should be

between 6.75 and 7.25 mm (0.27 and 0.29 in).

4 Bend the float arm if necessary to adjust

the setting.

Primary valve plate opening

5 With the throttle valve plate control lever in

contact with the stop, the primary valve plate

should be open (dimension X Fig. 3.22)

between 6.45 and 6.95 mm (0.25 and 0.27 in).

If adjustment is required, carefully bend the

lever stop.

Primary and secondary valve

plate openings

6 With the throttle control lever fully actuated

the valve plate gaps (X and Y Fig. 3.24) should

be:

X = 13.5 to 14.5 mm (0.53 to 0.57 in)

Y = 14.5 to 15.5 mm (0.57 to 0.61 in)

Fast idle

7 Close the choke valve plate fully and check

the gap (A) (Fig. 3.25) between the edge of the

throttle valve plate and the carburettor throat.

The gap should be between 0.90 and

0.95 mm (0.035 and 0.037 in), a twist drill is

useful for measuring this.

8 If adjustment is required, carry this out

using the screw and locknut.

Anti-flooding device

(mechanically-operated)

9 With the choke control pulled fully out, it

should be possible to open the choke valve

plate to give a gap (X) of between 7.0 and

7.5 mm (0.28 and 0.30 in). If adjustment is

required, carefully bend the stop on the

control lever (Fig. 3.26).

3•10 Fuel system

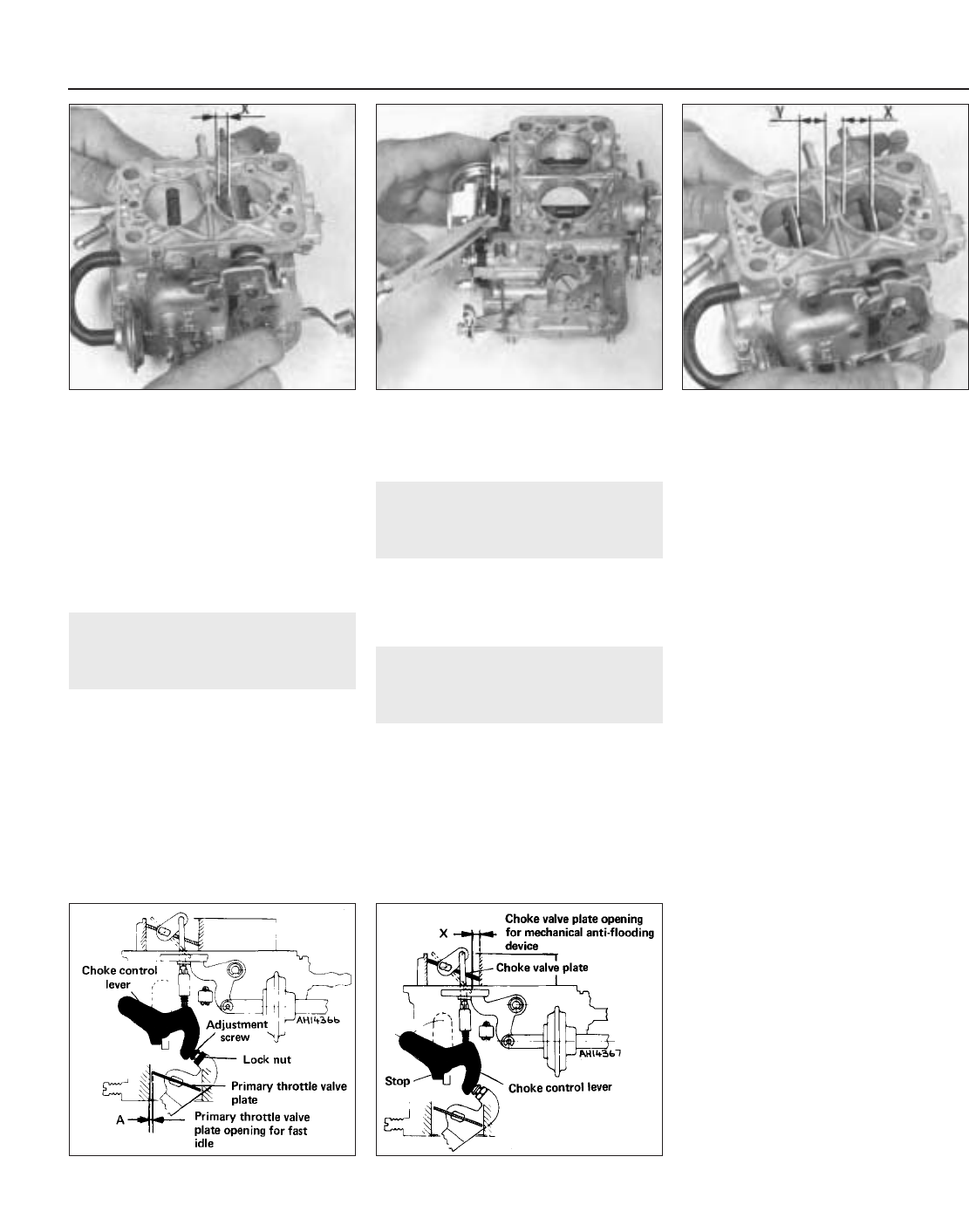

Fig. 3.26 Anti-flooding device (mechanical)

adjustment diagram

(Weber 30/32 DMTR 90/250) (Sec 14)

X = 7.0 to 7.5 mm (0.28 to 0.30 in)

Fig. 3.25 Fast idle adjustment diagram

(Weber 30/32 DMTR 90/250) (Sec 14)

A = 0.90 to 0.95 mm (0.035 to 0.037 in)

Fig. 3.24 Throttle valve plate openings

(Weber 30/32 DMTR 90/250) (Sec 14)

X (primary) = 13.5 to 14.5 mm (0.53 to 0.57 in)

Y (secondary) = 14.5 to 15.5 mm (0.57 to 0.61 in)

Fig. 3.23 Bending throttle lever stop

(Weber 30/32 DMTR 90/250) (Sec 14)

Fig. 3.22 Primary valve plate opening

(Weber 30/32 DMTR 90/250) (Sec 14)

X = 6.45 to 6.95 mm (0.25 to 0.27 in)