Data sheet

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

www.El-O-matic.com

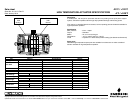

Description

EL-O-MATIC CSR-actuators have an excellent corrosion resistance in environments where the actuator is

in contact with chemicals like caustic soda. The CSR coating itself is resistant to at least 1000 hours of salt

spray test exposure. Together with the excellent mechanical properties, the CSR coating is "the" solution for

very harsh environments.

CSR actuator housing and caps are completely coated (inside and out) with a ceramic filled fluoropolymer

based epoxy resin, impregnated by a temperature of 240°C into the aluminum surface.

Approximately 40% of the coating is impregnated into the aluminum, 60% stays on the surface of the

component as a seal.

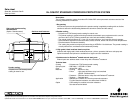

Technical data

Coating : Ceramic filled fluoropolymer based epoxy resin

Layer thickness : 20 microns

Salt spray test : DIN 50021 / ASTM B117: 1000 hours

Max. temperature : -4° to 176°F (20° to + 80°C)

Materials : Housing : Aluminum alloy

: Shaft : Aluminum hard anodized

: (Option : Stainless steel)

: Fasteners : Stainless steel

: Tagplate : Stainless steel

Application : Optional on all EL-O-MATIC actuators

Chemical resistances

Resistance to various inorganic chemicals, organic chemicals, gasolines, oils, detergents,

etc. is generally good to excellent, but also depends on temperature and/or concentration.

More detailed information available at data sheet A4.204.021

A4.204.02 Rev.B

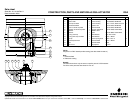

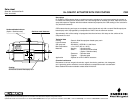

EL-O-MATIC ACTUATOR WITH CSR COATING CSR

CSR

Corrosion

Protected

Hard anodized aluminum

(Option : Stainless steel)

Stainless steel fasteners

Coating:

20 microns Ceramic filled epoxy resin

Sheet No.:

Date: June 2009