Data sheet

Copyright © Emerson Process Management. The information in this document is subject to change without notice.

Updated data sheets can be obtained from our website www.El-O-Matic.com or from your nearest Valve Automation Center USA: +1 813 319 0266 Europe: +31 74 256 10 10 Asia-Pacific: +65 6501 4600

www.El-O-matic.com

Description

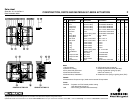

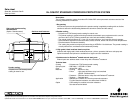

The corrosion protection system of standard El-O-Matic E&P series pneumatic actuators consist of the

following treatments or materials:

1 De-greasing

All aluminum parts are de-greased before the powder coating is applied by washing with an alkaline

solution to assure the best bonding between the aluminum surface and the coating.

2 Powder coating

- Polyester non-TGIC based powder coating for exterior use.

- The powder coating is applied cold using automatic electrostatic spray equipment and is cured at

minimum 190°C (374°F) offering excellent anti color fade and weather resistance.

- The powder coating thickness is 1.5 mm (37 microns) minimum, and 2 mm (50 microns) average.

- Good resistance against most chemical bases, acids, solvents, alkalis and oils at normal temperatures.

- Excellent exterior mechanical durability.

- The coating has passed a salt spray test according to ASTM B117 for 500 hours. The powder coating is

virtually solvent free, and therefore environmentally friendly.

3 High grade & hard anodized aluminum pinion

Actuators with high grade & hard anodized aluminum pinions, passed a 500 hours salt spray test.

Optional stainless steel pinions are available for a higher corrosion resistance.

4 Stainless steel or Deltatone

®

treated external steel parts

External parts are stainless steel or steel alloy with a Deltatone

®

treatment.

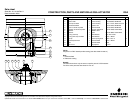

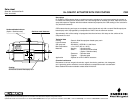

Technical data:

Coating : Polyester non-TGIC based powder coating

Salt spray test : DIN 50021 / ASTM B117: 500h

Color : Yellow (RAL 1007)

Materials : Housing : Aluminum alloy

: Pinion : High grade aluminum alloy, hard anodized

(Option : Stainless steel)

: Fasteners : Stainless steel or alloy steel with Deltatone

®

treatment

: Tagplate : Stainless steel

Application : Standard EL-O-MATIC E & P series pneumatic actuators

For Non-Standard actuators, see data sheet A4.204.05

Option : CSR coating for excellent corrosion resistance

See data sheet A4.204.02

High grade aluminum alloy,

hard anodized

(Option : Stainless steel)

Stainless steel fasteners

Powder coating:

Polyester non-TGIC based powder

coating for exterior use.

A4.204.01 Rev.B

EL-O-MATIC STANDARD CORROSION PROTECTION SYSTEM

Sheet No.:

Date: April 2011