1051 & 1052 H & J

Instruction Manual

Form 5587

November 2006

4

Specifications

Specifications are shown in table 1 for Type 1051

and 1052 actuators. Specifications for a given Type

1051 or 1052 actuator as it originally comes from the

factory are stamped on a nameplate attached to the

actuator.

Principle of Operation

The diaphragm rod moves down as loading pressure

is increased on top of the diaphragm. As the loading

pressure is decreased, the spring forces the

diaphragm rod upward.

The spring and diaphragm have been selected to

meet the requirements of the application and, in

service, the actuator should produce full travel of the

valve or other operated equipment with the

diaphragm pressure as indicated on the nameplate.

Consult the separate positioner instruction manual

for actuator principle of operation with positioner.

Installation

WARNING

Always wear protective gloves,

clothing, and eyewear when

performing any maintenance

operations to avoid personal injury.

To avoid personal injury or property

damage caused by bursting of

pressure retaining parts, be certain the

service conditions do not exceed the

limits given in table 1. Use pressure

limiting or pressure relieving devices

to prevent the diaphragm sizing

pressure from exceeding the maximum

allowable diaphragm sizing pressure.

Check with your process or safety

engineer for any additional measures

that must be taken to protect against

process media.

If installing into an existing

application, also refer to the WARNING

at the beginning of the Maintenance

section in this instruction manual.

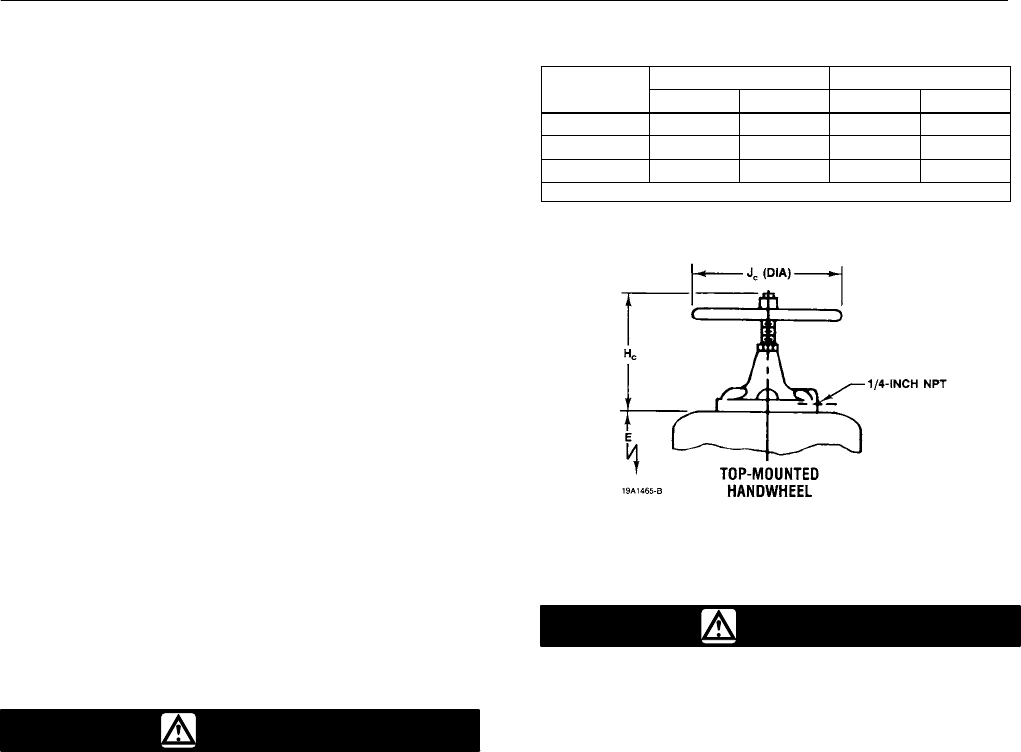

Top Mounted Handwheel

ACTUATOR

H

C

J

C

ACTUATOR

SIZE

mm Inch mm Inch

40 281 11.06 356 14.00

60 359 14.12 432 17.00

70

(1)

335 13.62 356 14.00

1. Size 70 available in Type 1052 only.

Figure 3. Top Mounted Handwheel

WARNING

To avoid personal injury or parts

damage, do not use an operating

pressure that exceeds the Maximum

Diaphragm Casing Pressure (table 1)

or produces a torque greater than the

Maximum Allowable Valve Shaft

Torque (see Catalog 14). Use

pressure-limiting or pressure-relieving

devices to prevent the diaphragm

casing pressure from exceeding its

limit.

Actuator Mounting

Use the following steps to connect the actuator to a

valve body or other equipment. Unless otherwise

specified, key numbers are shown in figures 12

and 13. Mounting dimensions are shown in figures 4,

5, 6, and 7.

Note

For an actuator with an H mounting

adaptation and a 22.2 through 38.1 mm

(7/8 through 1-1/2 inch) output shaft,

find dimensions and center of gravity

information in figures 3, 4, 5, 6, and 9,