1051 & 1052 H & J

Instruction Manual

Form 5587

November 2006

11

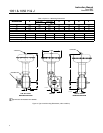

Center of Gravity Dimensions

ACTUATOR ACTUATOR

X Y

ACTUATOR

TYPE

ACTUATOR

SIZE

mm Inch mm Inch

1051

40 15 0.6 191 7.5

1051

60 10 0.4 361 14.2

40 15 0.6 241 9.5

1052

60 10 0.4 432 17.0

1052

70 23 0.9 488 19.2

Figure 9. Center of Gravity Dimensions

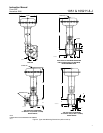

Loading Connection

1. Connect the loading pressure piping to the

pressure connection in the top of the diaphragm

casing.

For size 40 through 60 actuators, run either 1/4-inch

pipe or 3/8-inch tubing between the 1/4-inch

pressure connection and the positioner or automatic

controller.

For size 70 actuators, run either pipe or tubing

between the pressure connection and the positioner

or automatic controller. If necessary, remove

the 1/4-inch bushing in the pressure connection to

increase connection size.

2. Keep the length of pipe or tubing as short as

possible to avoid transmission lag in the control

signal. If an accessory (such as a volume booster or

a positioner) is used, be sure that the accessory is

properly connected to the actuator. If a positioner is

part of the assembly, the pressure connection to the

actuator will normally be made at the factory.

3. When the actuator is completely installed and

connected to the instrument, check for correct action

(air-to-open or air-to-close) to match the controlling

instrument. For successful operation, the actuator

stem and operating shaft must move freely in

response to the loading pressure change on the

diaphragm.

Adjustment

WARNING

Before performing any adjustment

steps, follow the steps in the

WARNING at the beginning of the

Maintenance section.

Type 1051 and 1052 Turnbuckle

Adjustment

Correct turnbuckle adjustment ensures that the valve

body or other operated equipment is correctly closed

when the actuator is against its travel stops. The

turnbuckle adjustment is the only adjustment

necessary on the Type 1051 actuator. Key numbers

used in this procedure are shown in figure 12 for

Type 1051 actuators and in figure 13 for Type 1052

actuators.

For accurate adjustment, remove the valve body or

other operated equipment from the pipeline.

A regulated air supply will be required to stroke the

actuator. Consult table 9 for the sizes of the three

open end wrenches required for this procedure.

1. Remove the access plate (key 59). Also remove

the machine screws (key 60), if present.

Note

For the most accurate adjustment of

the actuator, do not remove the cover

(key 33) during this procedure.

2. Loosen the lower locknut (key 16).