of turns required for removal. Remove hex jam nut from inner tie rod.

Remove adjusting nut from inner tie rod. Remove outer boot clamp. Cut

off and discard inner boot clamp. Mark location of breather tube (if

equipped) for reassembly reference. Slide boot from inner tie rod.

2) Slide shock damper ring on inner tie rod assembly back

toward rack. Place a wrench on flat side of rack to prevent turning.

Place another wrench on flats of inner tie rod. Rotate inner tie rod

counterclockwise until it separates from piston and rack. On "C", "F",

"N" and "Y" bodies, clean old Loctite from threads of rack and inner

tie rod. Remove shock damper ring.

Reassembly

1) Install shock damper ring. To prevent internal damage,

hold rack with a backup wrench during tie rod installation. Apply

Loctite No. 262 to inner tie rod threads. Install inner tie rod onto

rack. Tighten inner tie rod to specification. See

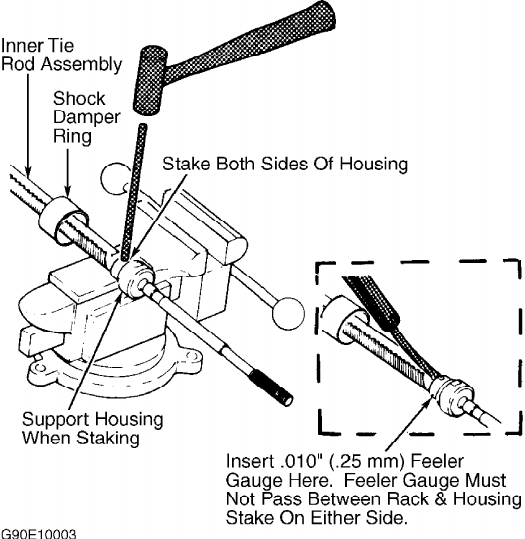

TORQUE SPECIFICATIONS. Stake tie rod fittings as shown in

illustration. See Fig. 11.

2) Ensure inner tie rod pivots freely in all directions, and

then stake both sides of inner tie rod to flats on rack. See Fig. 11.

Ensure both stakes are okay by inserting a .010" (.25 mm) feeler gauge

between rack and tie rod housing. Feeler gauge must not pass between

rack and housing stakes.

3) To complete reassembly, reverse disassembly procedure.

Apply grease to inner tie rod and housing before installing boots.

Install outer tie rod end with same number of turns as when removed.

Install new cotter pin at castle nut. DO NOT back off castle nut to

install cotter pin. Adjust toe-in as necessary. See appropriate

SPECIFICATIONS & PROCEDURES article in WHEEL ALIGNMENT. Fill and bleed

hydraulic system. See HYDRAULIC SYSTEM BLEEDING under LUBRICATION.

Fig. 11: Staking & Inspecting Inner Tie Rod

Courtesy of General Motors Corp.

TORQUE SPECIFICATIONS