Crankshaft/Camshaft Position

2-47

The optical crank angle sensor consists of a light

source, a light detector (photo-electric cell) and a rotor

plate, which is a slotted disk. Since the distributor shaft

and/or camshaft are linked to the rotor plate, they

move together. As the rotor plate rotates, the slits on

the disk interrupt a beam or light sent by the light

source to the light detector. This interrupting action

creates two pulse waveforms that are monitored by the

engine computer. The engine computer uses these

waveforms and other engine sensors to optimally

control ignition timing.

• Optical

SHUTTER

POWER

GROUND

SIGNAL

MAGNET

HALL

SWITCH

HIGH

SIGNAL

VOLTAGE

LOW

ROTATION

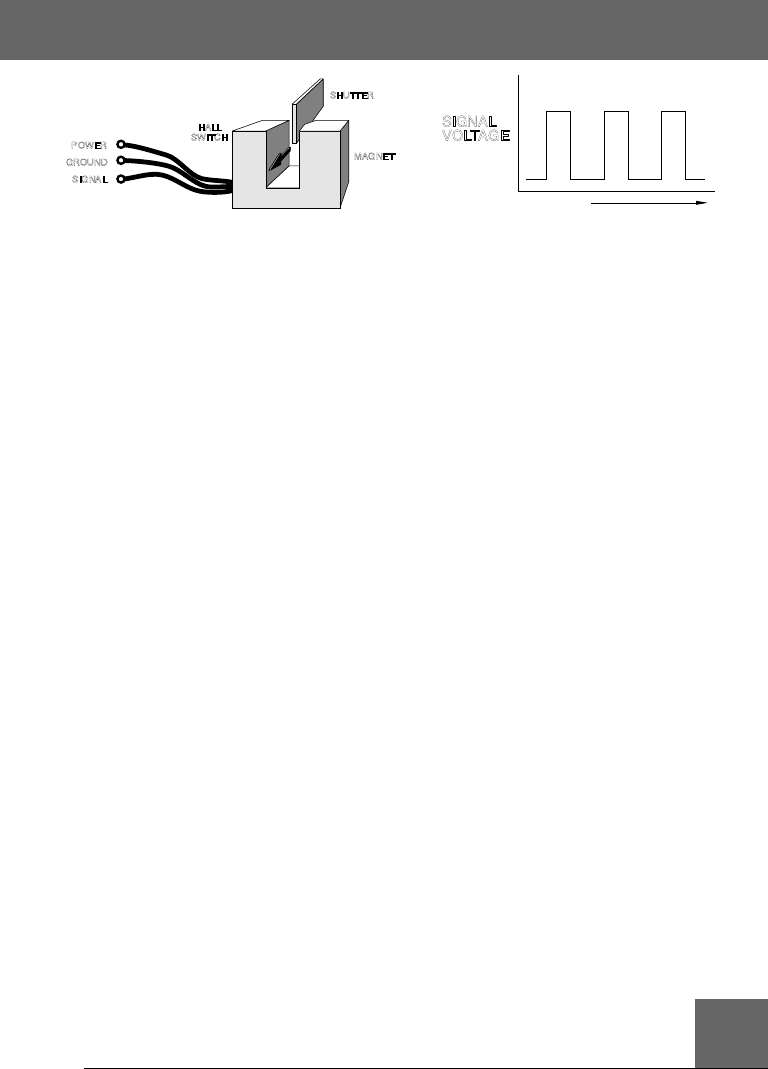

• Hall Effect The basic Hall effect sensor consists of a permanent

magnet and a small module containing a transistorized Hall

effect switch. (Power and ground connections are required

for operation.) A small air gap separates the sensor and the

magnet. The magnetic field causes the Hall switch to turn

on and send out a low voltage signal. If a metal strip (iron or

steel) is placed in the gap, it blocks the magnetic field from

reaching the Hall device. This causes the Hall switch to turn

off and send a high voltage signal out on the signal wire.

The metal strips (blades) are part of a disk or cup attached

to a rotating component such as the crankshaft or camshaft.

As the blades pass through the sensor gap, the voltage

signal switches high and low creating a series of pulses.

The computer determines rotational speed (or position) by

measuring how fast (or when) pulses appear.

The computer determines rotational speed (or position) by

measuring how fast (or when) pulses appear. Note: The

voltage pulses get larger when the teeth pass by more

quickly. Values can range from a fraction of a volt (crank

RPM) to over a hundred volts (high RPM).

Typical Hall Effect Sensor Typical Sensor Signal Voltage