140-072011 200/202 Series Page 21 of 24

4.3.2. Miscellaneous adjustments

Periodically, during normal operation, the ZERO should be checked and adjusted when required. If the

instrument is not shutting completely off when the Valve Override CLOSE function is active, or a

command of zero flow has been given, then the orifice may require approximately 1/8 turn clockwise.

4.4. End Cap Removal

The end cap on the inlet side must be removed to gain access to the filter or shunt assembly. First shut

off the supply of gas to the instrument. Disconnect the Swagelok fitting on the inlet and outlet sides of

the transducer, and remove it from the system plumbing. Remove the four hex bolts holding the end cap

to the instrument (see Figure 4.1). Carefully remove the end cap, filter, wave spring (if present) and

shunt, noting their order and proper orientation. The shunt can be severely damaged if dropped.

Examine the filter and shunt. If either is dirty or blocked, clean or replace as applicable. Reassembly is

the reverse of the removal procedure. Recalibration of the HFC is necessary.

4.5. Printed Circuit Board Replacement

In the unlikely event that the PC board fails, it is easily removed from the instrument and replaced with

a spare to minimize instrument downtime. Replacement of the PC board will require the instrument to

be recalibrated per Section 4.3.1.

Unplug the power cable from the top of the transducer. Remove the two jackscrews next to the “D”

connector and the two screws on the sides of the cover. Lift off the cover and unplug the four-wire

sensor plug and the two wire valve plug, noting their orientation prior to removal.

Remove the screw that holds the PC board to the sensor. Troubleshoot or replace as applicable.

Installation is the reverse of the above procedure. Recalibrate if any components were changed or if any

potentiometers were adjusted.

4.6. Sensor Replacement

If the sensor fails or becomes plugged it can be removed. Remove the cover and the PC board per

Section 4.5 above. Remove the three bolts holding the sensor to the instrument base. Remove the sensor

from the base noting the two O-rings (Parker 2-005, V884-75) between the sensor and the base. If the

sensor is plugged it can be cleaned by running a fine wire (approximately 0.008" diameter) through the

tube. If sensor needs replacement, obtain another from the factory and install it. Ensure that O-rings are

clean and intact. Install O-rings on seating surface, then carefully place sensor over O-rings and tighten

down the three screws evenly. Replacement of sensor will require recalibration per Section 4.3.1.

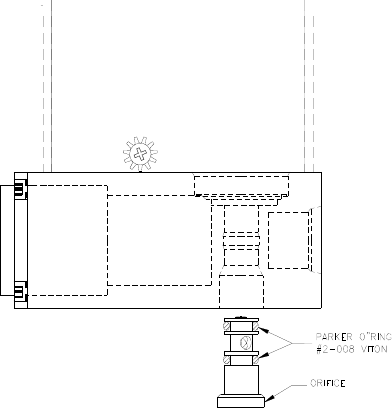

4.7. Orifice Changes

The orifice may require replacement if a large flow

range change is desired, if changing to a gas that has a

specific gravity significantly different than the original

gas, if a large change in the differential pressures across

the valve is desired or in the event that a small orifice

becomes plugged. Replacement orifices can be acquired

from the factory. The diameter of the orifice can be

calculated using the following procedure:

Orifice Changes:

A) Determine the minimum expected upstream

pressure (P

u

) in absolute pressure units (add

atmospheric pressure – 14.7 psia) and the maximum

expected downstream pressure (Pd) in absolute pressure

units for full flow conditions.