14 ► AL35 User Manual

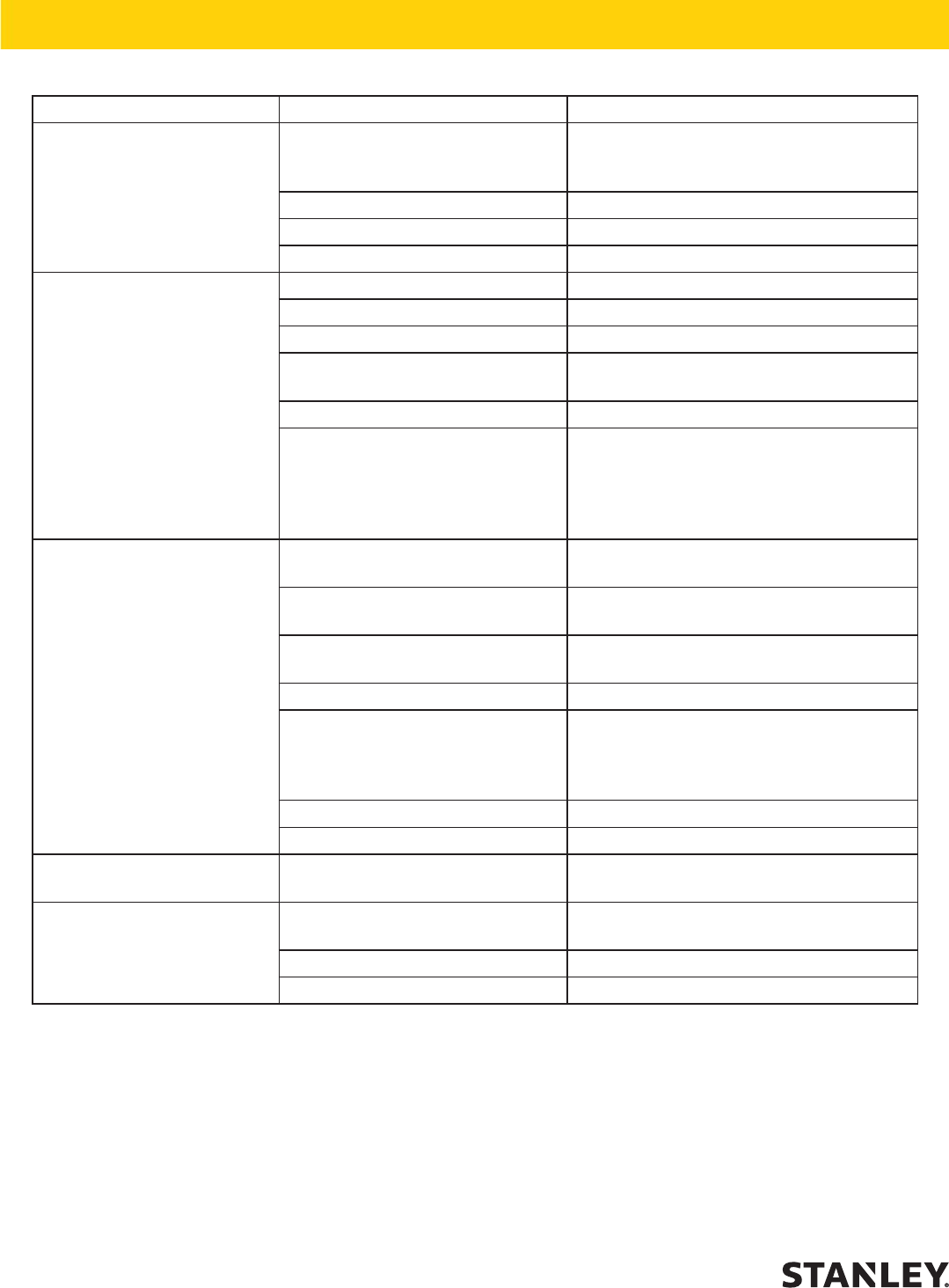

PROBLEM CAUSE REMEDY

Tool does not run. Power unit not functioning. Check power unit for power ow and

pressure (7-9 gpm/26-34 lpm, 2000

psi/140 bar.

Couplers or hoses blocked. Remove restriction.

Hyrevz motor failure. Inspect and repair.

Hydraulic lines not connected. Connect lines.

No electrical output. Open circuit breaker. Reset circuit breaker.

Faulty receptacle. Replace receptacle.

Loose/broken wires. Locate and repair.

Loss of residual magnetism. Flash and Field. Refer to section in this

manual.

Short circuit in rotor led or diodes. Return to an authorized service center.

Shorted AC or exciter stator

windings.

Check with Ohmmeter. Continuity should

exist between black/white and red/red

wires. No continuity from black/white to

red wire or any wire to ground. If a short is

found, replace the stator.

Low output. Hyrevz motor speed too slow. Check for proper ow of 7‑9 gpm/26‑34

lpm.

Unbalanced or excessive load. Balance load between circuits, load should

not exceed rated capacity.

High backpressure. Check for excessive backpressure, over

250 psi/17 bar.

Couplers/hoses blocked. Locate and remove blockage.

Oil too hot/cold. Above 150°F/66°C

or below 50°F/10°C.

Check power source for proper oil

temperature. Bypass cooler to warm

oil; or provide cooler to maintain proper

temperature.

Relief valve set too low. Adjust relief valve to 2000 psi/145 bar.

Motor worn. Inspect; repair/replace.

Output too high. Motor over-speeding. Check power unit for proper ow. 7‑9

gpm/26-34 lpm.

Alternator overheats. Overloaded. Reduce electrical load; load should not

exceed rated capacity.

Air intake plugged or covered. Clear air intake.

Windings covered with dirt. Clean windings.

TROUBLESHOOTING