125

MAINTENANCE

Suspension Maintenance

Loose nuts and bolts can reduce your snowmobile’s reliability and

cause needless repairs and down time. Before beginning any

snowmobile trip, a visual inspection will uncover potential problems.

Check the following items on a weekly basis or before any long trip:

n Check suspension mounting bolts for tightness.

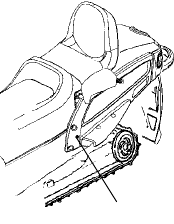

NOTE: The check the Indy 340 Touring rear

suspension mounting bolts, remove

the access plugs (A) in the skirt.

n Check rear idler wheel bolts for

tightness. See page 118 for torque specs.

n Check rear idler adjusting bolt

locknuts for tightness.

n Check front torque arm limiter strap condition.

n Check slide rail, Hi-fax condition greatly affects performance.

Have your dealer replace when worn to minimum thickness.

n Check track tension (beginning on page 118).

n Lubricate/grease all suspension components (see page 83).

n Check ski runner/skag condition.

n Check ski spindle bolts for tightness.

n Check tie rod end nuts for tightness.

Extended Storage

Off-season or extended storage of your snowmobile requires preventive

measures to aid against deterioration and to prolong the useful life of

many components.

Cleaning an d Preservation

Proper storage starts with cleaning, washing, and waxing the hood,

chassis, and plastic parts. Wipe down remaining surfaces with a damp

cloth. Clean and touch up with paint any rusted or previously painted

surfaces. Be sure that corrosive salt and acids are removed from

surfaces before beginning preservation with waxes and rust inhibitors

(grease, oil or paint).

The machine should be stored in a dry garage or shed, out of direct

sunlight, and covered with a fabric snowmobile cover. Plastic tarp may

cause condensation to form and damage snowmobile components.

A