66

MAINTENANCE

Lubrication R ecommendations

Check and l ubricate all components at the intervals outlined in the

Periodic Maintenance C hart beginning on page 62. Items not listed in

the chart should be lubricated at the General Lubrication interval.

NOTE: The a-arms and lower control arms are lubricated at the

factory, and no additional lubrication will be needed.

However , if these components are subjected to severe use,

grease zerks have been provided for additional lubrication at

the user’s discretion.

Lubrication Chart Key

" More often under severe use, such as wet or dusty conditions

L Polaris Premium All Season Grease or grease conforming to NLG

No. 2, such as Conoco Superlube M or Mobilegrease Special

F Use Polaris Premium U-Joint Lube every 500 miles, before long

periods of storage, or after pressure washing or submerging

∆ When suspension action becomes stiff, or after washing

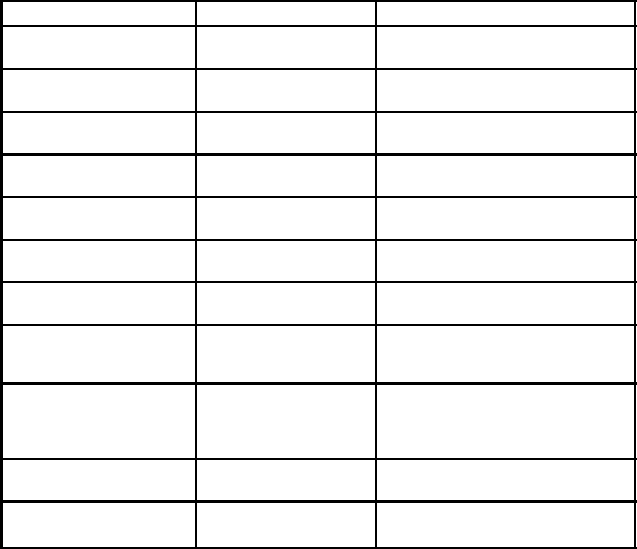

Item Lube Method

4-Cycle Engine Premium 4

Synthetic 0W40

Add to pr oper level on dipstick.

Brakes DOT 3 fluid only Maintain level between fill lines.

See page 35.

Drive chain(s) O-ring chain lube or

SAE 80/90

Lubricate.

(1) Transmission AGL Synthetic

Gearcase Lube

Maintain as recommended on

page 72.

(2) Front Gearcase ATV Angle Drive Fluid Maintain as recommended on

page 73.

(3) Front Prop Shaft Yoke FGrease Grease fittings

(3 pumps maximum).

(4) Swing Arm Bushings

"LGrease

Locate fittings on swing arm and

grease with grease gun.

(5) T ie Rod Ends

"L∆Grease

Lift boot, clean away dirt and

grease, apply fresh grease by

hand and reassemble.

(6) Front Hubs Premium Hub Lube Remove set screw in hubs. Rotate

wheels to 4 O’clock position. If lu-

bricant is not visible add more.

Reinstall set screw.

(7) Ball Joint

"LGrease

Locate fitting on back side of struts

and grease with grease gun.

(8) Axle Housing

"L Grease

Locate fittings on swing arm and

grease with grease gun.