Set Point Adjustment (Relay Output Only)

1) Adjust the flow rate through the line in which the flow sensor is

installed to the rate that corresponds to the desired relay trip point.

2) If the red LED on the back side of the sensor is not illuminated, use a

small flat bladed screwdriver to slowly turn the adjustment screw on the

set point potentiometer counter-clockwise until the red LED illuminates.

3) If the red LED is already illuminated, turn the adjustment screw on

the potentiometer clockwise until red LED turns off. Next, slowly

rotate the adjustment screw counter-clockwise until the red LED

illuminates.

4) Once the set point has been adjusted, the relay will operate as

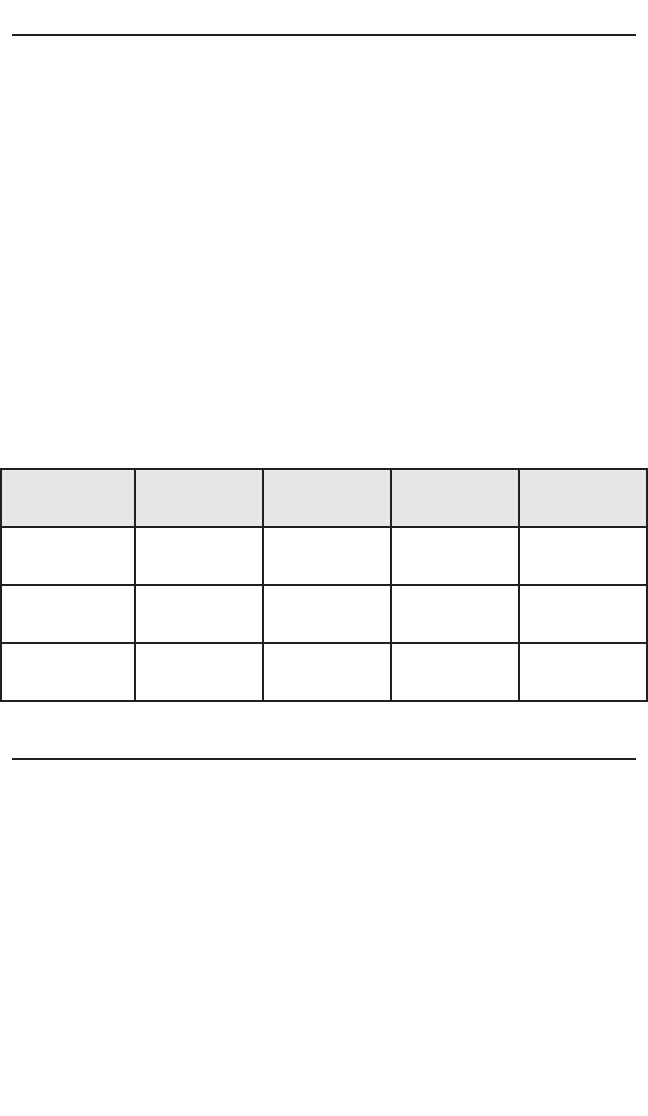

shown in the Truth Table illustrated in Table 2 below.

Table 2.: Truth Table - Relay Operation

Service and Maintenance

The sensor is designed to provide years of low maintenance service

in industrial environments. As with all mechanical rotating devices, the

bearing surfaces will wear with use. The life of the parts will depend

on factors such as cleanliness of the fluid, media, mounting orienta-

tion, temperature, fluid velocity and frequency of operation. The flow

sensor was designed with simple field-replacement of the rotating

parts in mind. To inspect or replace the rotating components:

(9)

Condition

Relay NC

Contact

Relay NO

Contact

Red LED Green LED

Flow rate<

set point

Open Closed Illuminated Illuminated

Flow rate >

set point

Closed Open

Not

Illuminated

Illuminated

Loss of power

to sensor

Open Closed

Not

Illuminated

Not

Illuminated