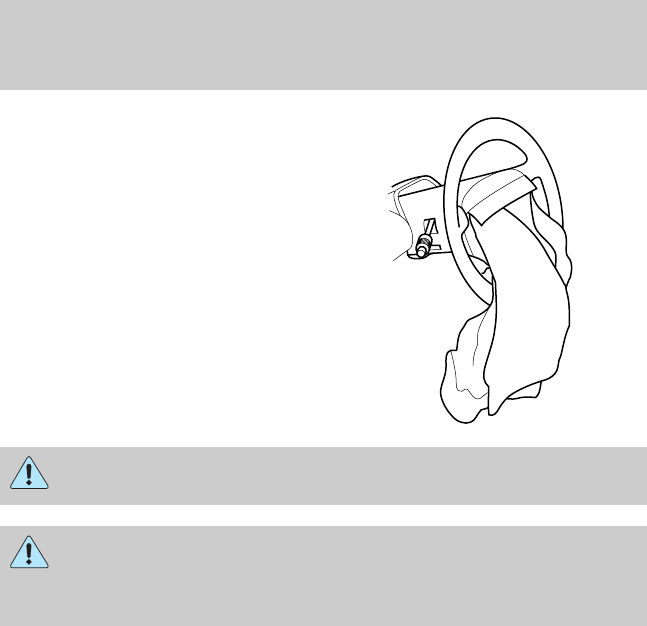

The air bags inflate and deflate

rapidly upon activation.

After air bag deployment, it is

normal to notice a smoke-like,

powdery residue or smell the burnt

propellant. This may consist of

cornstarch, talcum powder

(to lubricate the bag) or sodium

compounds (e.g., baking soda) that

result from the combustion process

that inflates the air bag. Small

amounts of sodium hydroxide may

be present which may irritate the

skin and eyes, but none of the

residue is toxic.

Several air bag system components get hot after inflation. Do not

touch them after inflation.

If the air bag is inflated, the air bag will not function again

and must be replaced immediately . If the air bag is not

replaced, the unrepaired area will increase the risk of injury in a

collision.

The SRS consists of:

• driver and passenger air bag modules (which include the inflators and

air bags),

• one or more impact and safing sensors,

• a readiness light and tone

• and the electrical wiring which connects the components.

The diagnostic module monitors its own internal circuits and the

supplemental air bag electrical system warning (including the impact

sensors), the system wiring, the air bag system readiness light, the air

bag back up power and the air bag ignitors.

Determining if the system is operational

The SRS uses a readiness light in the instrument cluster or a tone to

indicate the condition of the system. Refer to the Air bag readiness

Seating and safety restraints

82