MAINTENANCE WORK ON CHASSIS AND ENGINE

»

ENGLISH

26

Checking the basic setup of the telescopic fork

The precise riding sag of the telescopic fork cannot be determined for

various reasons. Similar to the shock absorber, smaller deviations in your weight

can be compensated by adjusting the spring preload. However, if your

telescopic fork bumps frequently (hard end stop during compression), you should

install harder fork springs to avoid damaging the telescopic fork and frame.

Changing the spring preload on the telescopic fork (250 SX-F/XC-F) *

The fork legs must be partly disassembled to change the spring preload (see

WP repair manual). Pretension spacers in various thicknesses are available

(see spare parts catalog).

NOTE: WP precisely adjusts the spring pressure by inserting pretension spa-

cers. Fluctuations in production are compensated with pretension spacers in

various heights. This can cause the fork springs in the fork legs to have dif-

ferent degrees of pretension. Fork springs and pretension spacers should

always stay together

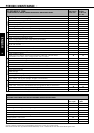

Changing the spring preload on the telescopic fork (250 XCF-W/

EXC-F/EXC-F Six Days)

The telescopic forks of these models come with a preload adjuster for easy

adjustment of the spring preload.

STANDARD-ADJUSTMENT:

– Completely unscrew the adjusting screws in a counterclockwise direction

– Screw the number of turns back in specified for your fork type in a clock-

wise direction.

WP 14.18.7D.04 . . . . . . . . . . . 2 WP 14.18.7D.34 . . . . . . . . . . . 2

Turning in a clockwise direction will increase the prestress, turning in a coun-

terclockwise direction will decrease the prestress.

Changing the spring preload will not affect the rebound damping adjustment.

Generally, if the spring preload is higher, the rebound damping should also

be set higher.

NOTE: Always turn the adjusting screws the same distance on both fork legs.

Different spring preloads on the fork legs will reduce the telescopic fork's response.

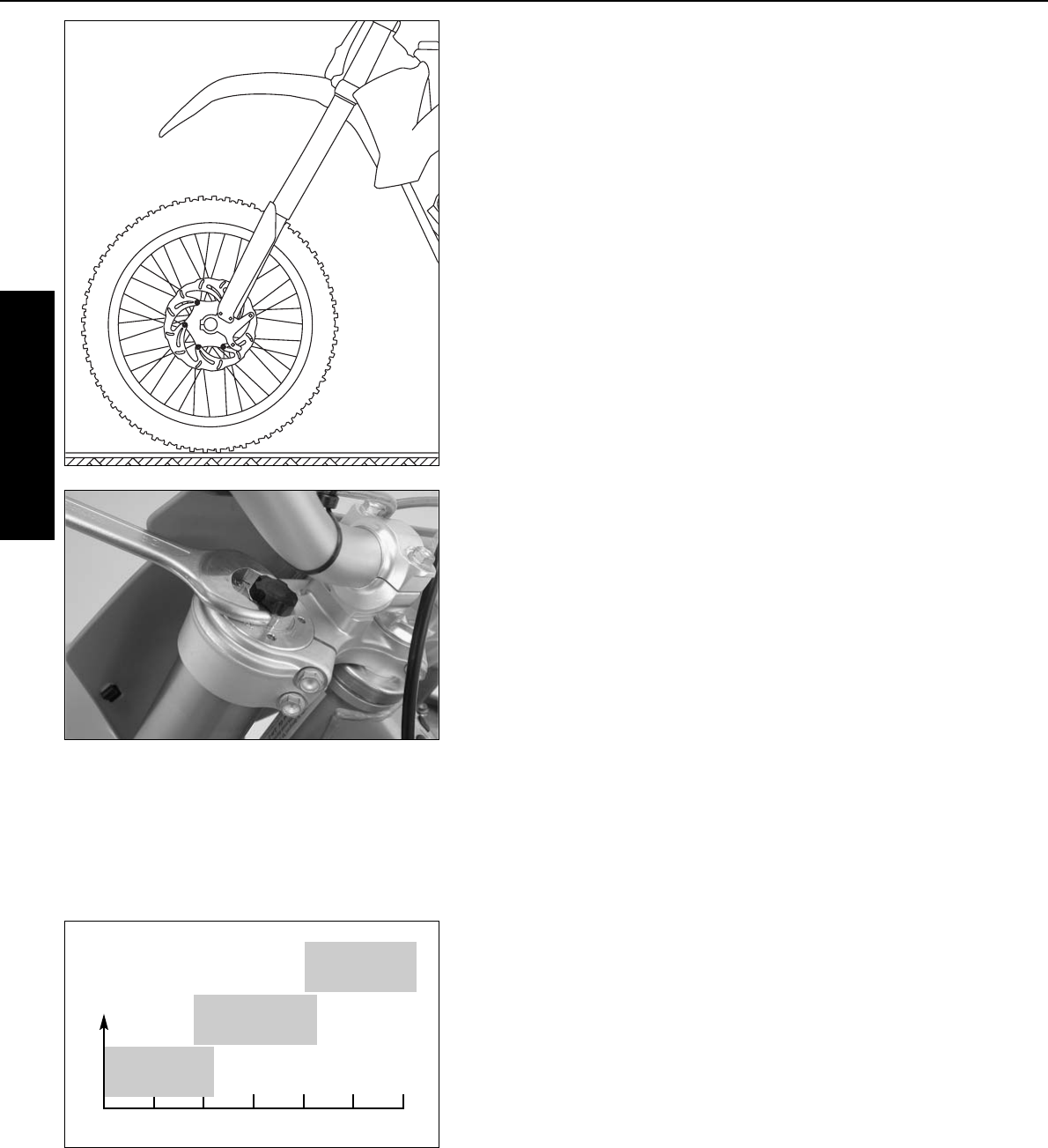

Replacing fork springs

If you weigh less than 75 kg or more than 85 kg, you should install the respec-

tive fork springs. The correct spring rate is shown in the illustrations. The stan-

dard spring is shown in bold print. The type number of the telescopic fork is

embossed on the fork fists.

If you are uncertain which spring to use, contact your KTM workshop.

According to our experience, the damping rate of the compression stage can

remain unchanged. The damping rate of the rebound stage can be reduced

by a few clicks for a softer spring or increased by a few clicks for a harder

spring.

65

SPRING RATE

70 75 80 85 90 95

RIDERS WEIGHT INCLUSIVE GEARS IN KILOGRAM

4,4 N/mm

4,2 N/mm

4,6 N/mm

4,4 N/mm

4,2 N/mm

4,0 N/mm

WP14.18.7D.03/28/34

WP14.18.7D.04