CLASS 500 ADVANCED KWH/DEMAND METER

5 62-0304—05

d. Connect the three AC mains power wires (PHASE A, PHASE B, and PHASE C) to their respective positions as labeled

on terminal block TB1. After all conductors are connected to their respective terminal block positions and tightened

down, verify each terminal block screw is securely fastened by gently tugging on each conductor. Verify that no conduc-

tor wires are frayed or shorting to adjacent terminal block positions.

5. External switch mechanism/in-line fuse installation:

a. To ensure a safe installation, the Class 500 Meter requires an external switch mechanism, such as a circuit breaker, be

installed to the Class 500 Meter MAINS input wiring. The switch mechanism must be installed in close proximity to the

Class 500 Meter and be easily reachable for the operator.

This device must also be marked as the disconnecting device for the Class 500 Meter.

b. Install 1/10 Amp Slow Activation inline fuses with the suitable voltage rating for each conductor phase at the MAINS

input to the meter. The fuses must be labeled to indicate voltage and current rating as well as element characteristics.

The fuse element must be a slow-activating type.

6. Once the MAINS wiring is complete, close the enclosure front panel and secure the panel to the enclosure using the lock-

ing mechanism. Activate the external circuit breaker or equivalent switch to apply AC MAINS power to the unit. The Class

500 Meter display should turn on and indicate total kWh accumulation reading.

NOTE: The unit display, clock, schedule, and other critical configuration parameters will be reset once the unit is completely

wired and ready for commissioning. Resetting and configuring these parameters must be done through a host computer,

locally or remotely, via an RS485 or ethernet link.

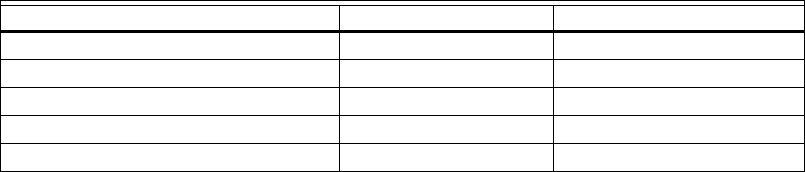

7. Using an AC voltmeter, verify that the input voltage readings are within the limits specified in Table 2.

NOTE: On 3-wire systems the voltages are measured Phase to Phase.

On 4-wire systems the voltages are measured Phase to Neutral.

8. Remove power from the unit by de-energizing the external switch.

Current Sensor Installation and Wiring

Once the AC voltages have been confirmed to be within acceptable limits, you are ready to install the current sensors. The main

power board contains three header connectors located at the bottom center of the board, TB2, TB3, and TB4.

TB2: Phase A current sensor input

TB3: Phase B current sensor input

TB4: Phase C current sensor input

The Class 500 meters are shipped with split-core current sensors.

1. Split-core current sensor: This sensor opens so that it can be attached around the circuit conductor being monitored with-

out interrupting power.

2. Split-core current sensors output a 0-2 VAC signal, proportional to the current being measured.

Installing the Split Core Current Sensor Assembly

1. Each phase being monitored will require one two-piece current sensor assembly. Therefore, a three-phase meter will

require three (3) assemblies. Open the two-piece current sensor assembly by releasing the nylon clamp using a flat head

screwdriver.

2. Reassemble the current sensor assembly around the conductor(s) to be monitored. Ensure the current sensor halves

marked “Load” are both facing the load side of the conductor. The colored arrow will be on the source side of the conductor

being monitored and MUST be pointed in a clockwise direction around the conductor being monitored. Tighten the nylon

clamp to complete the assembly.

Table 2. Input voltage limits

Meter Input Voltage/Configuration Normal Voltage Limits (+/-10%)

120/208V, 3Ø, 4 Wire 120 VAC 108 to 132 VAC

277/480V, 3Ø, 4 Wire 277 VAC 249 to 305 VAC

346/600V, 3Ø, 4 Wire 346 VAC 311 to 381 VAC

240V, 3Ø, 3 Wire 240 VAC 216 to 264 VAC

480V, 3Ø, 3 Wire 480 VAC 432 to 528 VAC