Installation

4 306674V

Installation

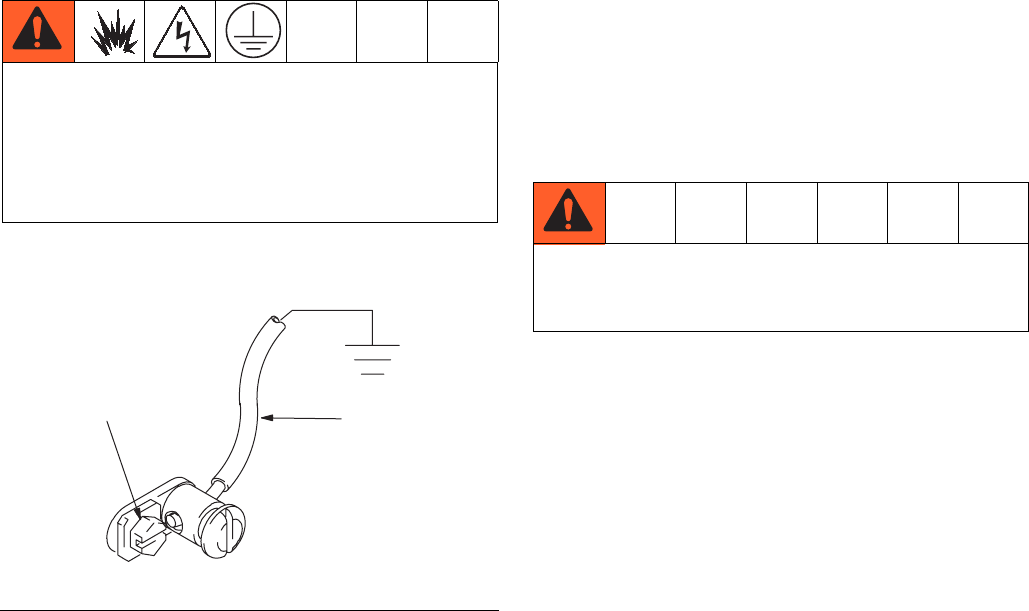

Grounding

Pump: Use a ground wire and clamp as shown in FIG. 1.

Air and fluid hoses: Use only electrically conductive

hoses.

Air compressor: Follow manufacturer’s recommenda-

tions.

Dispense valve: Ground through connection to a prop-

erly grounded fluid hose and pump.

Object being dispensed: follow local code.

Solvent pails used when flushing: Follow local code.

Use only conductive metal pails, placed on a grounded

surface. Do not place the pail on a nonconductive sur-

face, such as paper or cardboard, which interrupts

grounding continuity.

To maintain grounding continuity when flushing or

relieving pressure: hold metal part of the spray

gun/dispense valve firmly to the side of a grounded

metal pail, then trigger the gun/valve.

To ground the pump: Remove the ground screw (Z)

and insert through the eye of the ring terminal at end of

ground wire (Y). Fasten the ground screw back onto the

pump and tighten securely. Connect the other end of the

ground wire to a true earth ground. See F

IG. 1. To order

a ground and wire clamp, order Part No. 222011.

Mounting the Pump

• Select a convenient location for the equipment to

ensure easy operator access to the pump air con-

trols, sufficient room to change supply containers,

and a secure mounting platform.

• If you are mounting the pump directly on the supply

tank, position the pump so its intake valve is no

more than 1 inch (25 mm) from the bottom of the

container. Mount the pump to the cover or other suit-

able mounting device.

Typical Installation

Mount the pump to suit the type of installation planned.

Very heavy lubricant may require an inductor plate. See

page 17 for the mounting hole layout and dimensions.

Install the airline accessories in the approximate order

shown in F

IG. 2. Install a bleed-type master air valve (B)

within easy reach of the pump, upstream from the air

regulator. Install an air filter (C) to remove harmful dirt

and moisture from your compressed air supply. For

automatic air motor lubrication, install an air line oiler (D)

close to the pump air inlet. Install an air regulator (E) to

control pump speed.

The equipment must be grounded to reduce the risk

of static sparking and electric shock. Electric or static

sparking can cause fumes to ignite or explode.

Improper grounding can cause electric shock.

Grounding provides an escape wire for the electric

current.

FIG. 1

Y

Z

Mount the pump securely so that it cannot move

around during operation. Failure to do so could result

in personal injury or equipment damage.