1035/El-O-Matic Actuator

Instruction Manual

Form 5417

February 2007

16

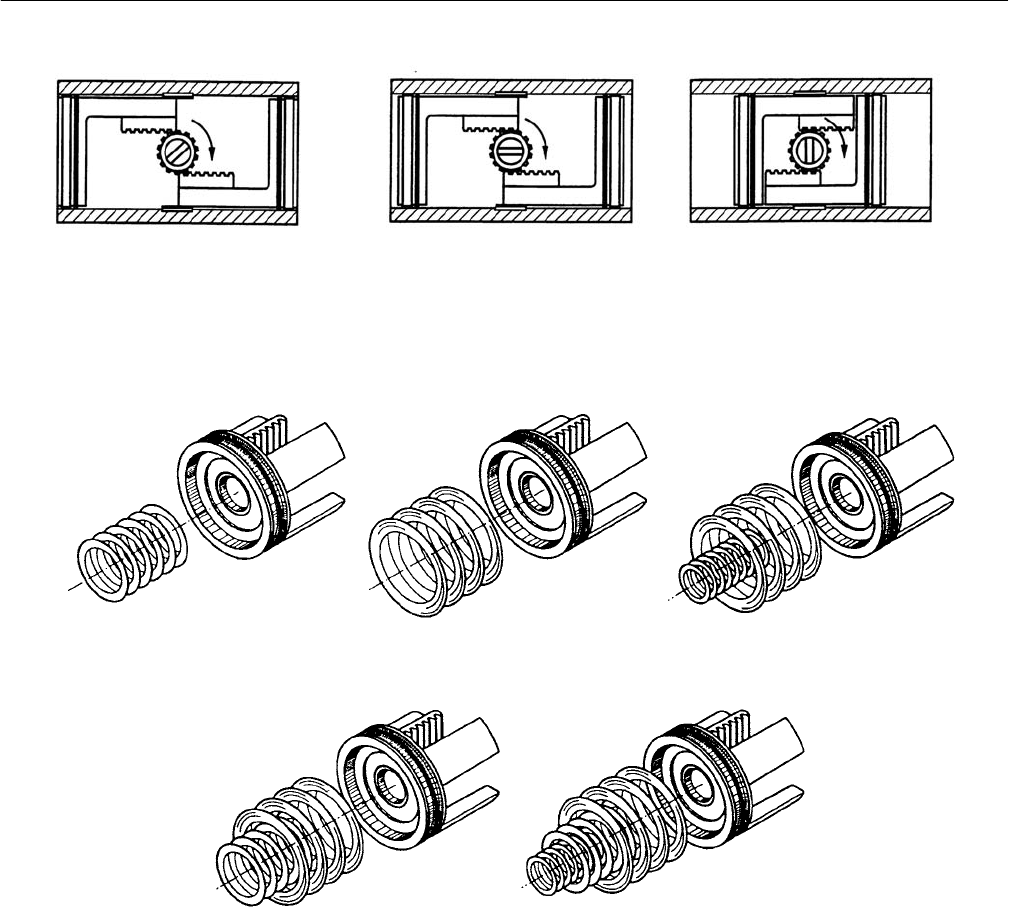

Figure 7. Installing Actuator Pistons

NOTE: PISTONS ARE SHOWN IN THE CODE A POSITION

START

PISTONS AT

BODY ENDS

PISTONS AT

BODY CENTER

45_

0_

90_

75B0509-A

A7042 / IL

Figure 8. Spring Arrangement for E Series Actuators

SPRING SET 2

MID SPRING

SPRING SET 3

OUTER SPRING

(OR MID +INNER

SPRING AS AN

ALTERNATE)

SPRING SET 4

INNER AND OUTER SPRING

SPRING SET 5

MID AND OUTER SPRING

SPRING SET 6

INNER, MID AND OUTER SPRING

ELO A 4.202

A7040 / IL

Spring Return E Series Actuators

Spring return E Series actuators use from two to a

maximum of six springs. One, two, or three springs

are inserted into each end cap (see figure 8). Refer

to the nameplate to verify the number of springs

required.

Each end cap spring pack incorporates a travel stop

adjustment screw (key 37). This may be used to

adjust the end of the stroke for valve seating in

either the “fail open” or “fail closed” arrangements.

1. When installing used springs in a spring return

actuator, ensure that the springs are replaced in the

identical position from which they were removed.

2. If a spring return actuator is being repaired due to

spring failure, replace all the springs in the actuator.

3. To assemble the spring assembly, install the

spring(s) into the end cap. Be sure that all springs

are seated correctly in the end cap (key 5) and in the

spring holder (key 9). Place the spring holder and

washer on top of the springs, and install the

adjustment screw (keys 34 and 37).