micrometer to trace the cause of the trouble.

It is very seldom that any trouble of this nature

will be experienced when fitting the

crankshaft.

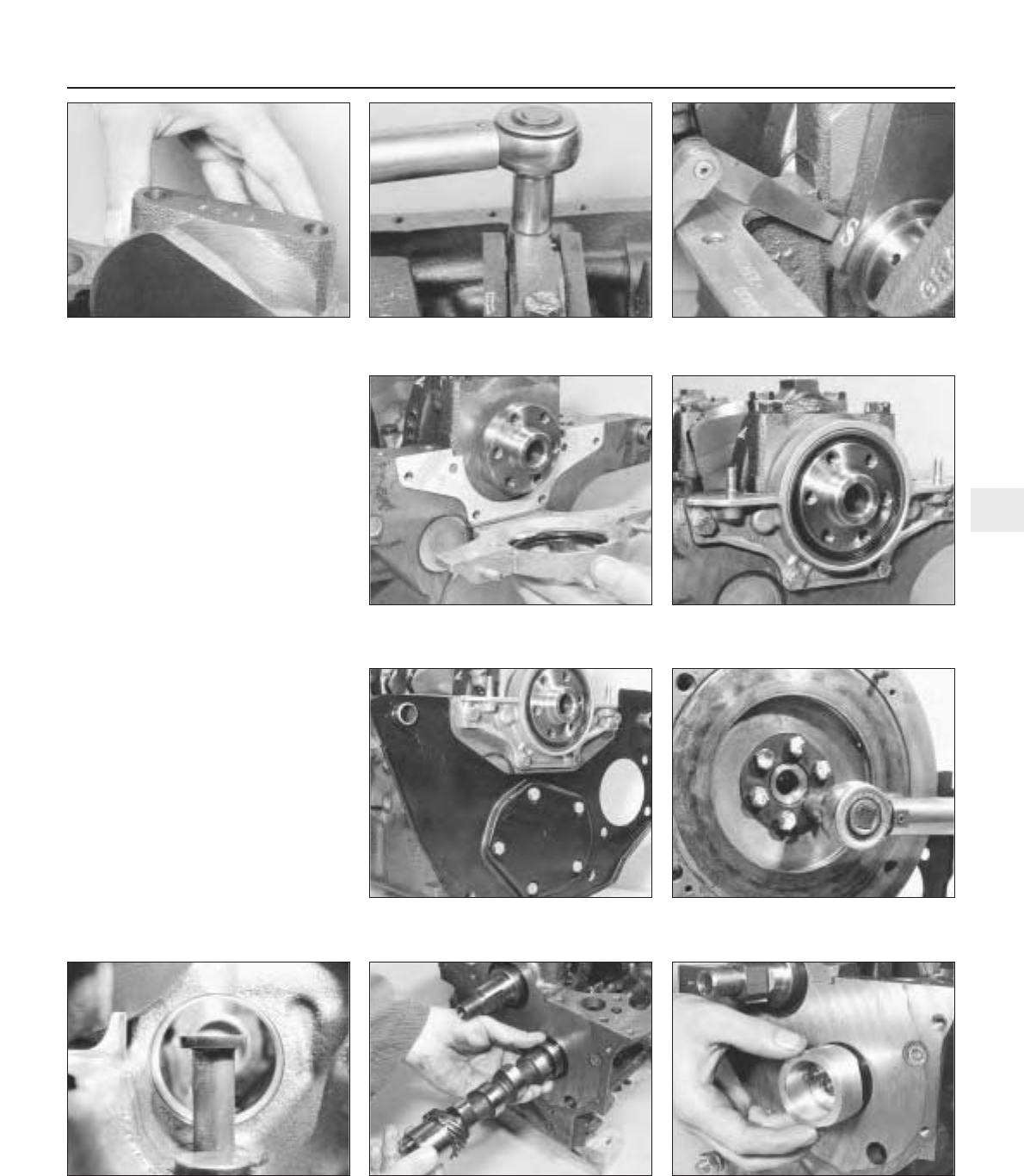

9 Tighten the main bearing bolts to the

specified torque wrench settings (photo).

10 Using a dial gauge or feeler blades

inserted between a thrust washer and the

crankshaft, check the crankshaft endfloat. If it

exceeds the specified limit, the thrust washers

can be changed for thicker ones (photo).

11 Bolt on the crankshaft rear oil seal carrier

using a new gasket. The carrier should have

been fitted with a new oil seal and the seal lips

greased (photos).

12 Fit the engine rear plate (photo).

Flywheel

13 Offer the flywheel to the crankshaft. With

pistons No. 1 and 4 at TDC, the dimple on the

flywheel must be uppermost.

14 Screw in and tighten the bolts to the

specified torque. The crankshaft may be held

against rotation by either jamming the starter

ring gear or placing a block of wood between

one of the crankshaft webs and the inside of

the crankcase (photo).

Camshaft

15 Oil the cam followers and return them to

their original positions (photo).

16 Oil the camshaft bearings and insert the

camshaft, taking great care not to damage the

bearings with the cam lobes. Fit the front

bearing, chamfer inwards (photos).

903 cc engine 1•21

20.10 Checking crankshaft end float20.9 Tightening main bearing cap bolts20.6 Fitting a main bearing cap

20.16B Camshaft front bearing20.16A Fitting camshaft

20.11B Crankshaft oil seal and carrier

fitted

20.11A Crankshaft rear oil seal carrier and

gasket

20.14 Tightening flywheel bolts20.12 Engine rear plate

20.15 Cam followers

1