fitting, as during removal. Note that the

compression rings are brittle, and will snap if

expanded too far.

206 If new pistons are to be fitted, they must

be selected from the grades available, after

measuring the cylinder bores. Normally, the

appropriate oversize pistons are supplied by

the dealer when the block is rebored.

207 Whenever new piston rings are being

installed, the glaze on the original cylinder

bores should be removed using either

abrasive paper or a glaze-removing tool in an

electric drill. If abrasive paper is used, use

strokes at 60º to the bore centre-line, to

create a cross-hatching effect.

Engine/transmission

mountings - renewal ¡

208 The engine/gearbox assembly is

suspended in the engine compartment on

three mountings, two of which are attached to

the gearbox, and one to the engine.

Right-hand mounting

209 Apply the handbrake, then jack up the

front of the vehicle and support it securely on

axle stands.

210 Suitable lifting tackle must now be

attached to the engine in order to support it as

the engine mounting is removed. No lifting

brackets are provided, so care must be taken

when deciding on an engine lifting point. In the

workshop, a right-angled bracket was made up

by bending a suitable piece of steel plate. The

bracket was then bolted to the engine using the

rear right-hand camshaft housing securing bolt

with suitable packing washers.

211 Attach the lifting tackle to the bracket on

the engine and just take the weight of the

assembly.

212 Working under the vehicle, unbolt the

engine mounting bracket from the cylinder

block, and unbolt the mounting from the

body, then withdraw the bracket/mounting

assembly.

213 Unscrew the nut and through-bolt,

counter holding the bolt with a second

spanner or socket, and separate the mounting

from the bracket.

214 Fit the new mounting to the bracket, and

tighten the nut to the specified torque, while

counterholding the through-bolt using a

suitable spanner or socket.

215 Refit the mounting bracket to the cylinder

block, and tighten the securing bolts to the

specified torque.

216 Refit the mounting to the body and

tighten the securing bolts to the specified

torque.

217 Disconnect the lifting tackle from the

engine, and remove the engine lifting bracket.

218 Lower the vehicle to the ground.

Left-hand mountings

219 Apply the handbrake, then jack up the

front of the vehicle and support it securely on

axle stands.

220 Suitable lifting tackle must now be

attached to the gearbox lifting bracket in

order to support the weight of the assembly

as the mounting is removed.

221 Attach the lifting tackle to the bracket on

the gearbox, and just take the weight of the

assembly.

222 Working under the vehicle, unbolt the

mounting bracket from the gearbox, and

unbolt the mounting from the body, then

withdraw the bracket/mounting assembly.

223 Proceed as described in paragraphs 213

and 214.

224 Refit the mounting bracket to the

gearbox, and tighten the securing bolts to the

specified torque.

225 Refit the mounting to the body and

tighten the mounting bolts to the specified

torque.

226 Disconnect the lifting tackle from the

engine.

227 Lower the vehicle to the ground.

PART C: ENGINE REMOVAL

AND DISMANTLING

Method of removal - general

1 The engine (complete with transmission) is

disconnected and lowered downwards

through the engine compartment, then

withdrawn from the front underside of the car.

1372 cc engine/

transmission - removal

and separation #

Warning: Refer to the beginning

of Section 9 before starting any

work.

2 Depressurize the fuel system as described

in Section 9 of this Chapter.

3 Disconnect the battery negative lead.

4 Mark the position of the hinges on the

underside of the bonnet, then with the aid of

an assistant, unscrew the hinge bolts and lift

the bonnet clear of the car. Store the bonnet

in a safe area.

5 Drain the engine coolant.

6 Drain the engine and transmission oils.

7 Disconnect and remove the air filter.

8 Disconnect the coolant hoses from the

engine, including the hose to the inlet

manifold.

9 Detach the ignition coil (HT) lead from the

distributor.

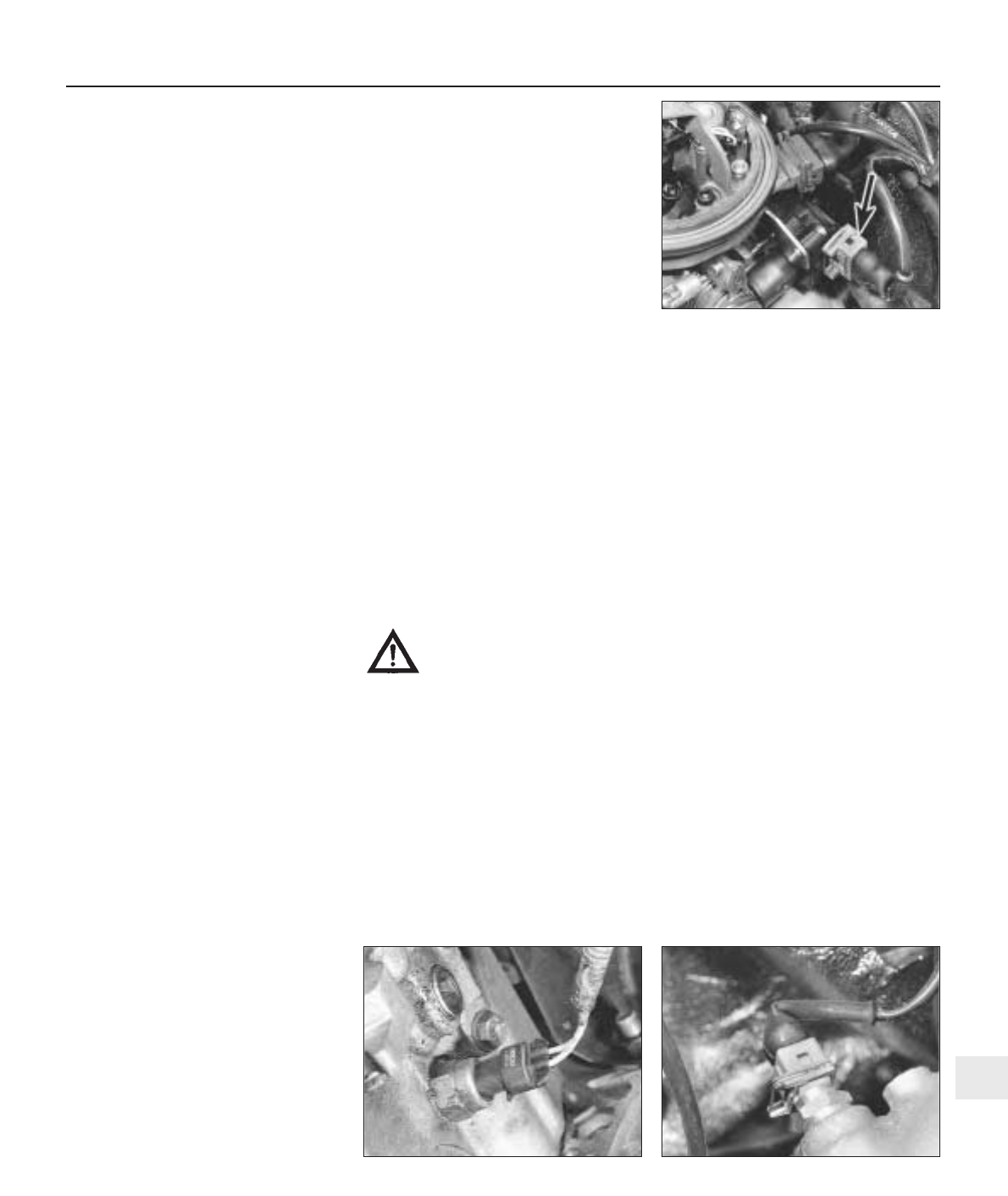

10 Compress the retaining clip and detach

the engine idle speed actuator lead from the

SPi unit (photo).

11 Disconnect the brake servo vacuum pipe

from its connector on the inlet manifold.

12 Disconnect the throttle cable from the SPi

unit.

13 Disconnect the engine speed sensor lead.

14 Release and detach the reversing light

lead from the switch on the transmission

(photo).

15 Before disconnecting the hydraulic hose

from the clutch slave cylinder, remove the

filler cap from the reservoir and place a piece

of polythene sheet over the filler neck, then

refit the cap; this will help prevent excess fluid

loss. Once disconnected, plug the hose and

its cylinder connection to prevent the ingress

of dirt into the hydraulic system.

16 Disconnect the wiring connector from the

alternator.

17 Position a clean rag under the fuel supply

and return hose connections to the SPi unit,

then slowly unscrew the hose clips to release

the system pressure; catch fuel leakage in the

rag and dispose of it safely. Detach the hoses

and plug them to prevent ingress of dirt and

any further fuel leakage. Position the hoses

out of the way.

18 Detach the wiring connector from the

engine coolant temperature sender unit

(photo).

19 Release the retaining clip and detach the

wiring connector from the throttle position

switch. Also detach the associated earth

leads from the cylinder head.

Supplement: Revisions and information on later models 13•49

7C.14 Reversing light switch and lead 7C.18 Engine coolant temperature sender

and wiring connector

7C.10 Engine idle speed actuator/SPi unit

lead connection (arrowed)

13