20 When reassembling, pack the joint with

special FIAT Tutela MRM2 lubricant; if this is not

available, use molybdenum disulphide grease.

21 The reference groove on the outer track

must be assembled so that it is towards the

final drive when refitted (photo).

22 Pack the joint and the inside of the boot

liberally with the specified grease.

23 If a new joint is being fitted to the shaft,

make sure that the joint and shaft colour

codes match.

Shaft colour Joint colour

Blue Blue or white

Red Red or white

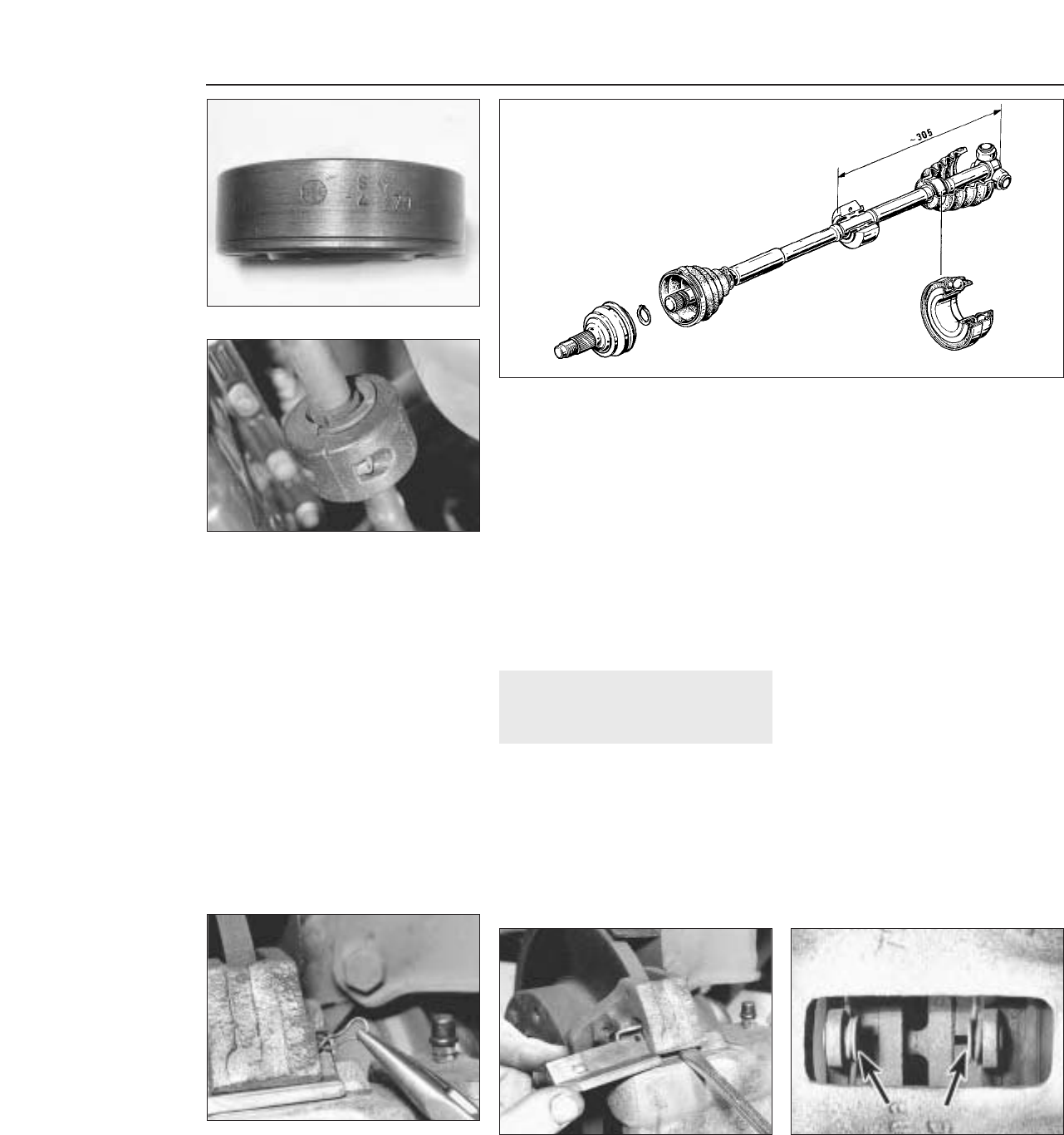

Right-hand driveshaft damper

weight (1108 cc and

1372 cc ie models) -

removal and refitting #

24 A damper weight is fitted to the longer,

right-hand driveshaft to reduce vibration (photo).

25 It should not be necessary to remove the

damper weight unless the driveshaft is to be

renewed, or the weight has been damaged.

26 The weight is in two halves, and can be

removed by simply unscrewing the two clamp

bolts securing the two halves to the

driveshaft. Note that the weight locates on a

rubber mounting which is split along its

length, and can simply be pulled from the

driveshaft for renewal if necessary.

27 Refitting is a reversal of removal, but

ensure that the damper weight is positioned

exactly as shown in Fig. 13.101.

14 Braking system

PART A: BRAKING

SYSTEM - GENERAL

Front brake pads - all later

models

1 The front brake pads have modified

anti-vibration plates and a wire spring fitted to

prevent them from vibrating and knocking in

operation.

2 On some models the clip securing the disc

pad locking block is located on the inboard

end, rather than the outer end (shown in

Chapter 8). To ensure correct reassembly,

check the location of the original block

retaining clip before dismantling the brake

unit. The alternative fixing arrangement is

shown in the accompanying photos, in this

instance on a 1372 cc ie model (photos).

PART B: BRAKING SYSTEM

- TURBO IE MODELS

Description

1 Disc brakes are fitted to all four wheels on

the Turbo ie models. The front disc brakes are

of different design from those used on other

models, in that the wear in the pads can be

checked without the need to remove the

caliper cylinder housing.

Front disc pads - renewal ™

2 Raise the front of the car and remove the

roadwheels.

3 Check the thickness of the friction material

on the pads through the aperture in the caliper

cylinder body. If the thickness of the material

is 1.5 mm or less, then the pads on both sides

must be renewed (photo).

13•100 Supplement: Revisions and information on later models

14B.3 Front disc pads (arrowed) on Turbo

ie model

14A.2B Front brake locking block

orientation with inboard retaining clip

14A.2A Front brake pad locking block is

secured by a clip on the inboard end of the

brake unit on certain models

Fig. 13.101 Correct position of driveshaft damper weight on 1108 cc and 1372 cc ie

models (Sec 13)

Dimensions in mm

13.24 Right-hand driveshaft damper weight

13.21 Outer track reference groove