bearing caps with a soft non-fluffy rag, then fit

the lower halves of the bearing shells to their

seats. Again, note that the centre (No. 3)

bearing shell is plain, whereas all the other

shells have oil grooves (photo).

9 Lubricate the crankshaft journals and the

upper and lower main bearing shells with

clean engine oil (photo).

10 Carefully lower the crankshaft into the

crankcase (photo). If necessary, seat the

crankshaft using light taps with a

rubber-faced hammer on the crankshaft

balance webs.

11 Lubricate the crankshaft main bearing

journals again, the fit the No. 1 bearing cap.

Fit the two securing bolts, and tighten them as

far as possible by hand.

12 Fit the No. 5 bearing cap, and as before

tighten the bolts as far as possible by hand.

13 Fit the centre and then the intermediate

bearing caps, and again tighten the bolts as

far as possible by hand.

14 Check that the markings on the bearing

caps are correctly orientated as noted during

dismantling - ie the identification grooves

should face towards the timing side of the

engine, then working from the centre cap

outwards in a progressive sequence, finally

tighten the bolts to the specified torque

(photo).

15 Check that the crankshaft rotates freely.

Some stiffness is to be expected with new

components, but there should be no tight

spots or binding.

16 Check that crankshaft endfloat is within

the specified limits, as described in paragraph

70 of Part C in this Section.

17 Examine the condition of the front and

rear crankshaft oil seals and renew if

necessary with reference to Part B of this

Section. It is advisable to renew the oil seals

as a matter of course unless they are in

perfect condition.

18 Lubricate the oil seal lips with clean

engine oil, then carefully fit the front and rear

oil seal housings using new gaskets.

Pistons and connecting rods -

refitting

19 Refer to Part B of this Section.

Oil pump - refitting

20 Refer to Part B of this Section.

Sump - refitting

21 Refer to Part B of this Section.

Flywheel - refitting

22 Refer to Part B of this Section. When the

flywheel is bolted in position, refer to Chapter

5 for details and refit the clutch unit.

Auxiliary shaft - refitting

23 Refer to Part C of this Section.

Cylinder head - refitting

24 Refer to Part B of this Section. Note that

this procedure describes cylinder head

refitting complete with the camshaft housing

assembly and manifolds as a complete unit.

Details of refitting the camshaft housing (and

followers) to the cylinder head will be found

separately in Part B.

Timing belt and covers -

refitting

25 Refer to Part B of this Section.

Engine/transmission -

reconnection and refitting #

Note: A suitable hoist and lifting tackle will be

required for this operation. New locktabs will

be required for the exhaust

downpipe-to-manifold nuts, and suitable

exhaust assembly paste, will be required when

reconnecting the downpipes to the exhaust

manifold.

26 Before attempting to reconnect the

engine to the gearbox, check that the clutch

friction disc is centralised as described in

Chapter 5, Section 8. This is necessary to

ensure that the gearbox input shaft splines

will pass through the splines in the centre of

the friction disc.

27 Check that the clutch release arm and

bearing are correctly fitted, and lightly grease

the input shaft splines.

28 Mate the engine and gearbox together,

ensuring that the engine adapter plate is

correctly located, and that the gearbox

locates on the dowels in the cylinder block,

then refit the engine-to-gearbox bolts and the

single nut, but do not fully tighten them at this

stage. Ensure that any brackets noted during

Supplement: Revisions and information on later models 13•53

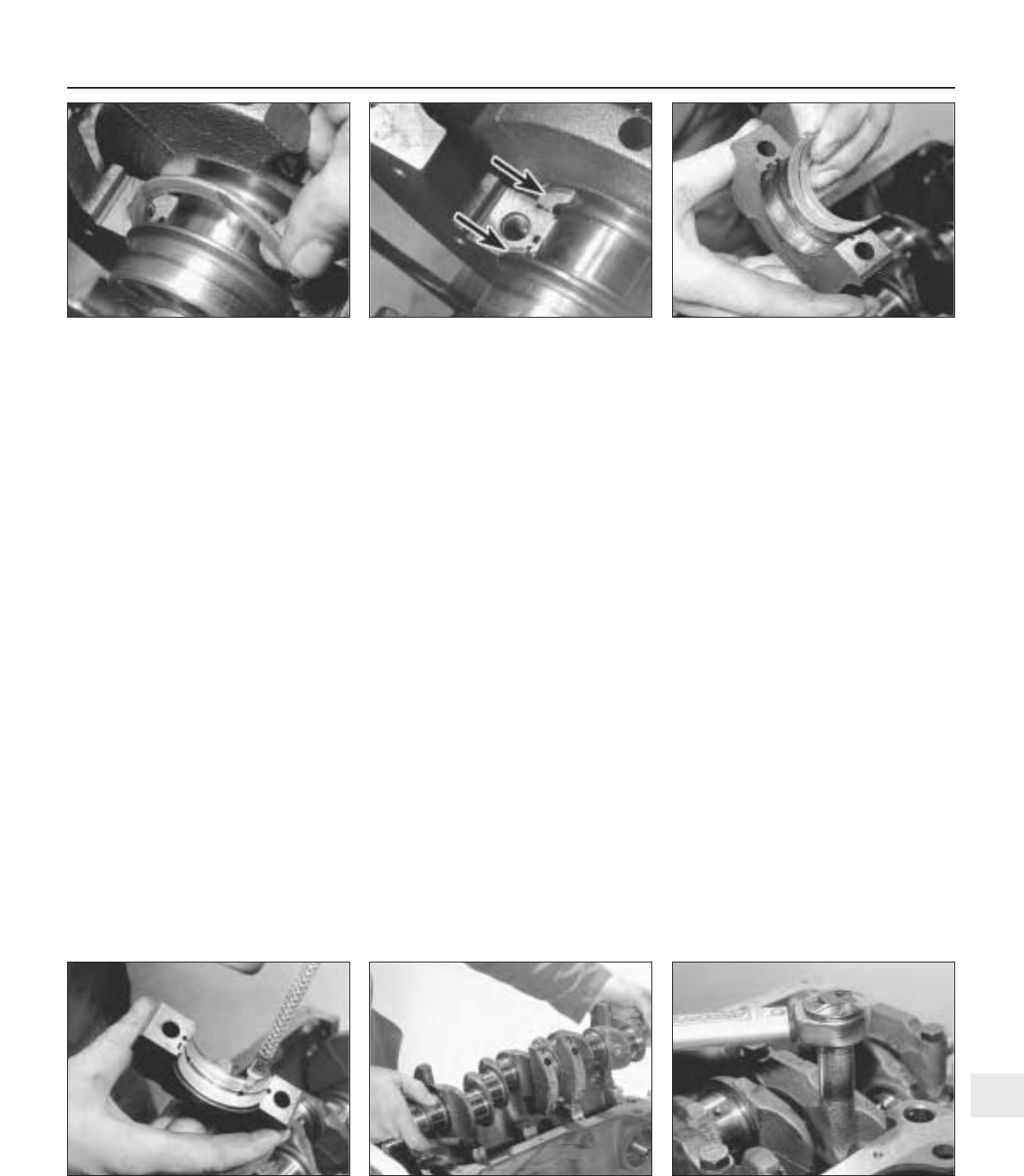

7D.8 Locate the bearing shells into the

main bearing caps . . .

7D.7B . . . sliding them into position each

side of the No. 5 main bearing

7DS.14 Tighten the main bearing cap bolts

to the specified torque setting

7D.10 Lower the crankshaft into position7D.9 . . . and lubricate the shells

13

7D.7A Locate the thrust washer . . .