Engine oil cooler -

removal and refitting ¡

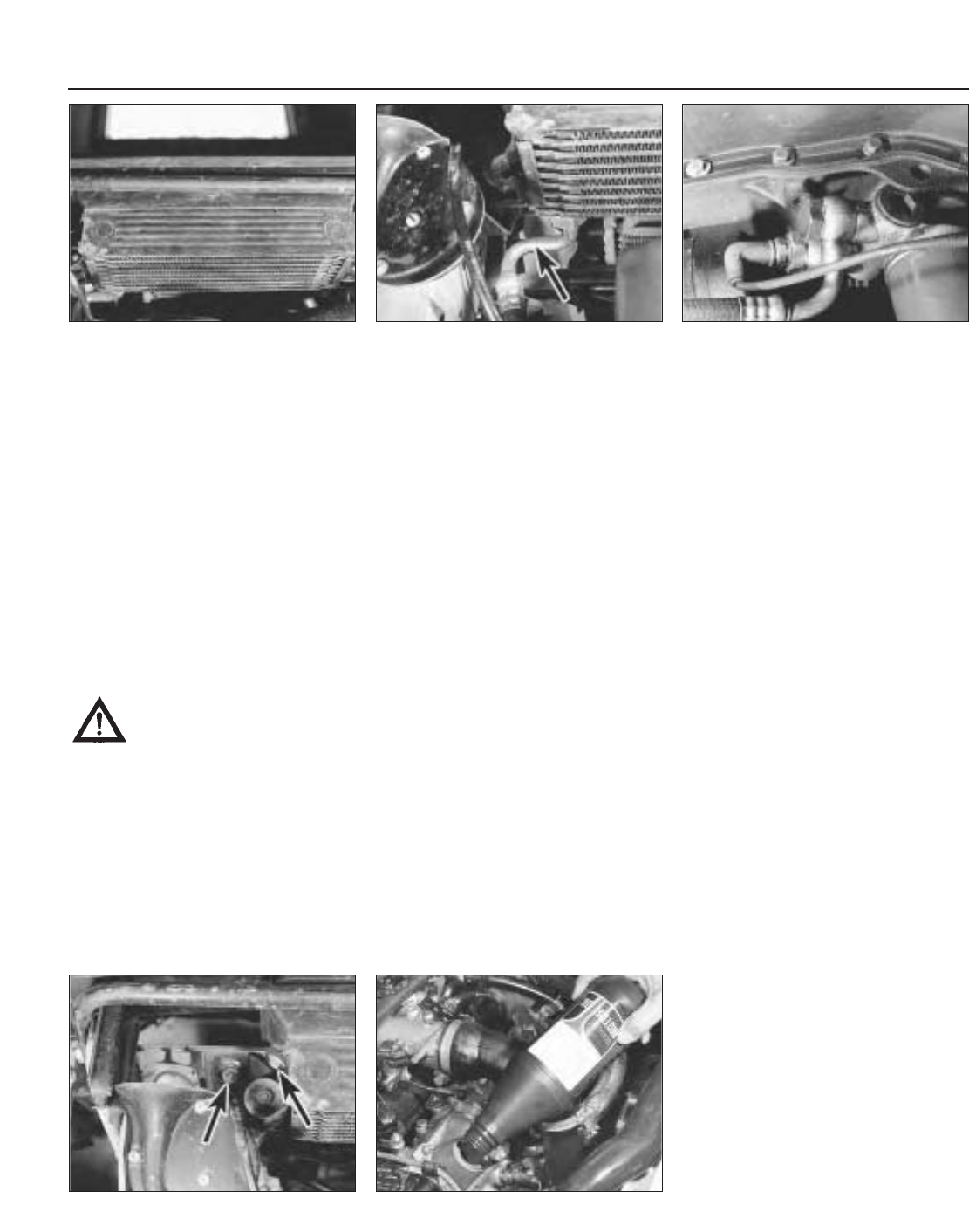

23 The oil cooler is mounted behind the front

bumper/spoiler (photo).

24 Disconnect the oil flow and return hoses,

either from the cooler or the oil filter cartridge

mounting base. Be prepared for some

leakage of oil (photos).

25 Unscrew the mounting bolts and remove

the oil cooler heat exchanger (photo).

26 When refitting, make sure that the banjo

union sealing washers are in good condition.

PART C: ENGINE REMOVAL,

DISMANTLING, REASSEMBLY

AND REFITTING

Engine/transmission -

removal and separation #

Warning: Refer to the beginning

of Section 9 before starting any

work.

1 Refer to Chapter 1, Section 35, and carry

out the operations described in paragraphs 1

to 11.

2 Disconnect the excessive air pressure

switch from the inlet manifold.

3 Disconnect the ducts and remove the

airflow meter.

4 Disconnect the leads from the spark plugs

and the distributor LT connector, and unbolt

and remove the distributor from the rear end

of the camshaft carrier.

5 Disconnect the fuel return hose from the

pressure regulator.

6 Disconnect the fuel inlet hose from the

injector rail.

7 Disconnect the wiring plugs from the fuel

injectors.

8 Disconnect the leads from the oil pressure

sender unit, the low oil pressure switch and

the coolant temperature switch.

9 Remove the hose/pipe assemblies from the

intercooler.

10 Disconnect the throttle control rod at the

balljoint.

11 Disconnect the hoses and ducts from the

turbocharger and the mechanical bypass

valve.

12 Disconnect the leads from the engine

speed and anti-knock sensors.

13 Raise the front of the car and support it

securely. As the engine/transmission will

eventually be lowered to the floor, make sure

that there is sufficient clearance under the

front end for the assembly to be withdrawn. If

the car is over an inspection pit, then the car

need only be raised enough to lift the

roadwheels from the floor.

14 Remove the front roadwheels.

15 Disconnect the transmission earth cable.

16 Working under the car, remove the engine

shields from under the wheel arches.

17 Remove the engine oil cooler, and the

intercooler.

18 Unscrew the fixing screws and disconnect

the driveshafts from the flanges at the

transmission final drive. The right-hand

driveshaft will not release until the upper bolt

on the suspension strut-to-hub carrier clamp

has been removed, and the hub assembly

tilted downwards.

19 Disconnect the exhaust downpipe from

the manifold, and then remove the front

section of the exhaust system.

20 Disconnect the coolant return pipe from

the turbocharger.

21 Disconnect the gearchange control rods

from the transmission selector rod. Do this by

unscrewing the self-locking nut from the bolt

which connects the clevis fork.

22 Attach suitable lifting gear to the engine

lifting eyes, and take the weight of the

engine/transmission.

23 Disconnect the left-front, centre-rear and

the right-hand engine/transmission mountings.

Do this by removing the bolts from the

diamond-shaped mounting plates there is no

need to disturb the flexible mounting centre

bolts.

24 Lower the engine/transmission to the floor

and withdraw it from under the car.

25 Carry out the operations described in

Chapter 1, Section 35, paragraphs 27 to 31.

Engine dismantling and

reassembly

26 The operations are essentially as

described for the 1301 cc engine in Chapter 1,

but reference must be made to Sections 9

and 10 of this Chapter for the procedures for

removing and refitting the components of the

fuel injection, turbocharger and ignition

systems.

Engine/transmission -

reconnection and refitting

27 The operations are a reversal of those

described in paragraphs 1 to 25, but

otherwise the following (photo).

a) Tighten all nuts and bolts to the specified

torque.

b) Use a new gasket at the exhaust

downpipe-to-manifold flange.

c) Check and adjust the clutch pedal travel.

d) Refill the cooling system.

e) Refill the engine and transmission with oil.

f) Reconnect the battery, negative lead

last.

13•36 Supplement: Revisions and information on later models

6C.27 Filling the engine with oil6B.25 Oil cooler mounting bolts (arrowed)

6B.24B Connections at oil filter cartridge

mounting base

6B.24A Oil cooler pipe connection

(arrowed)

6B.23 Oil cooler