operation twice. Also prior to making

adjustments ensure that the supplementary

air valve pipe is in good condition, with no

leaks. Compress the air valve pipe using a

pair of grips to prevent incorrect adjustment

caused by a defective supplementary air

valve.

15 The air cleaner must be connected when

checking and/or adjusting the engine idle

speed. To adjust, turn the adjuster screw in

the required direction to set the engine idle

speed to that specified.

16 It is unlikely that the mixture will require

adjustment and unless this is proven by

measuring the exhaust gases using a CO

content analyser, its setting should not be

altered. As with idle speed adjustment, the

engine must be at its normal operating

temperature when making this check and

adjustment. It is also necessary to ensure that

the ignition idle advance is as specified.

Checking and adjustment must not be made

with the engine cooling fan, air conditioning

(where fitted) or other related items switched

on.

17 If adjustment to the mixture is required,

prise free the tamperproof plug from the front

of the mixture adjustment screw in the control

unit, then turn the screw as required. Turn the

screw inwards (clockwise) to increase the CO

content or outwards (anti-clockwise) to

weaken it.

Throttle position switch adjustment

18 This switch will not normally require

adjustment having been set during

production. The switch should not be

loosened off or reset unless absolutely

necessary.

19 If a new switch is fitted it can be set by

loosely fitting the securing bolts, turning the

switch fully anti-clockwise, then clockwise

until one of the internal contacts is felt to click

into engagement. Hold the switch in this

position and tighten the retaining screws.

Reconnect the wiring multiplug to the switch.

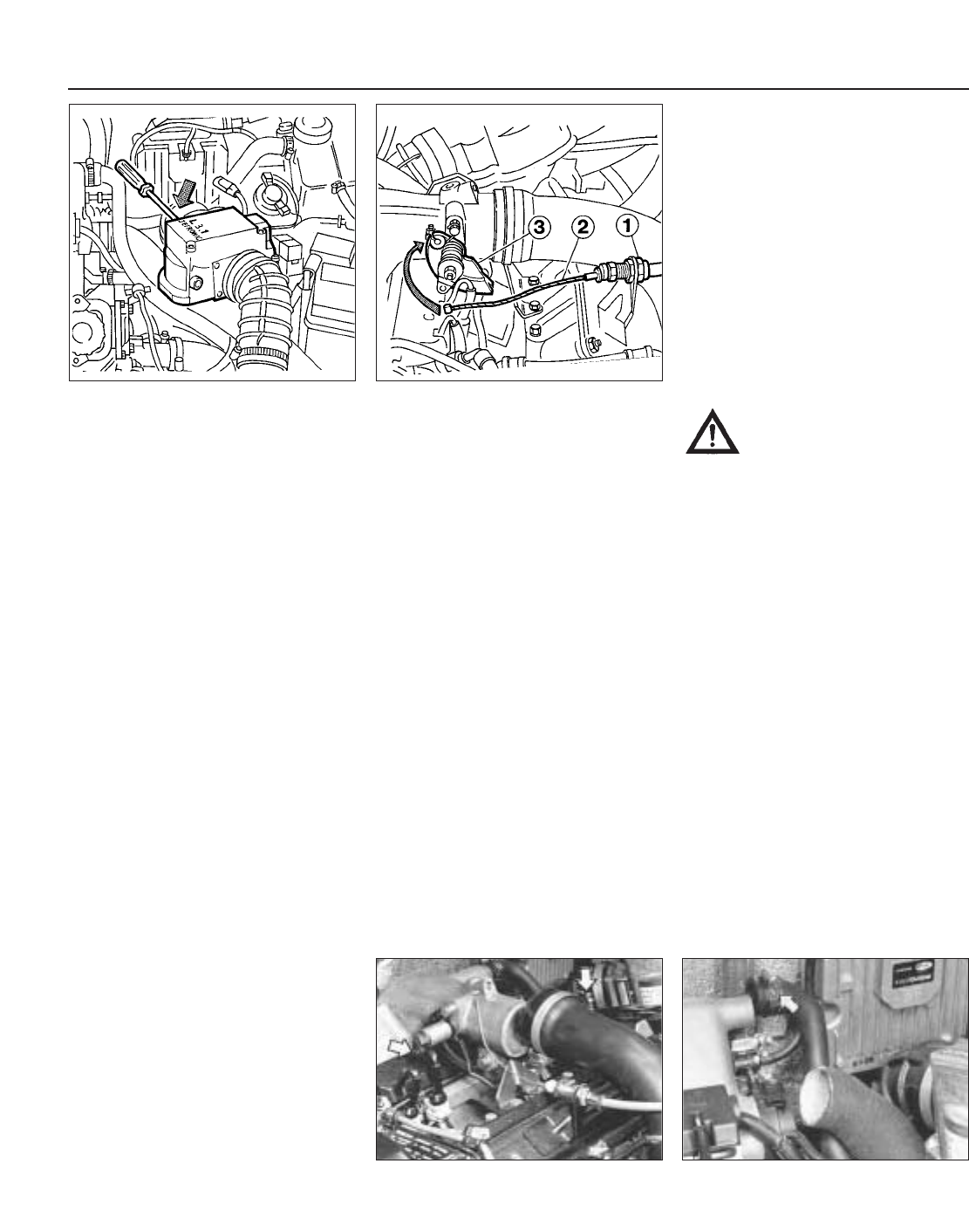

Accelerator cable adjustment

20 If the accelerator cable is removed or

detached from the support bracket at the

throttle control housing at any time, care must

be taken to adjust it correctly. When the inner

cable is connected to the throttle quadrant,

set the outer cable in the bracket so that the

inner cable has a minimal amount of free play,

yet does not prevent the throttle valve from

fully closing.

21 When the engine is restarted, check that

the engine idle speed is as specified and that

the action of the accelerator is satisfactory.

Fuel pump and supply system checks

22 Although the following basic checks can

be made to the fuel pump and fuel supply

system, specialised equipment is required to

undertake full and accurate tests of the fuel

supply system. Such checks must therefore

be entrusted to a FIAT dealer or a fuel

injection specialist.

23 If the fuel pump is suspected of

malfunction, a basic check can be made by

turning the ignition on and listening around

the area of the pump unit to hear if it is

operating. The pump is located on the

underside of the car, just forward of the fuel

tank. If the pump fails to operate, check that

the pump fuse is sound and that its

connection (and also that the relay) are clean

and secure.

24 The pump can be further checked as

described previously for the LE2 fuel injection

system fuel pump in Part C of this Section.

Supplementary air valve check

25 With the engine at its normal operating

temperature, allow it to idle, then pinch the

supplementary air valve hose using suitable

pliers as shown in Fig. 13.52 and check to see

if the engine speed drops by more than 50

rpm. If it does, the supplementary air valve is

defective and in need of renewal.

Injection system

components -

removal and refitting ¡

Warning: Refer to the beginning

of this Section before starting

any work.

26 With the exception of the items mentioned

below, the various components of the fuel

injection system are removed in the same

manner as that described for the equivalent

items in Part C of this Chapter.

27 Disconnect the battery negative lead

before carrying out any of the removal and

refitting operations. Where fuel lines are to be

disconnected it will first be necessary to

depressurise the injection system.

Airflow meter

28 Release the retaining clips and detach the

air intake and outlet ducts from the airflow

meter.

29 Ensure that the ignition is switched off,

then disconnect the multiplug from the ECU.

Unscrew the retaining bolts and remove the

airflow meter complete with the ECU.

30 If required, the ECU can be separated

from the airflow meter by undoing the

securing bolts.

Throttle valve housing/inlet manifold

31 Loosen off the retaining clip and detach

the air intake duct from the throttle housing,

the air cooling hoses for the injectors and the

supplementary air valve.

32 Detach the accelerator cable from the

throttle linkage.

13•80 Supplement: Revisions and information on later models

Fig. 13.56 Disconnecting the injector air

cooling hoses and the supplementary air

valve hose on the 1372 cc Turbo ie engine

(Sec 9E)

Fig. 13.55 Disconnecting the air intake

duct and accelerator cable from the

throttle housing on the 1372 cc Turbo ie

engine (Sec 9E)

Fig. 13.54 Accelerator cable adjustment

on the 1372 cc Turbo ie engine (Sec 9E)

1 Adjuster 3 Quadrant support

2 Inner cable

Fig. 13.53 Mixture adjustment screw

location on the 1372 cc Turbo ie engine

(Sec 9E)