3 The centralised door locking system can

operate independently of the key.

4 To gain access to the lock solenoid and

linkage, remove the front door trim panel as

described in Chapter 12.

5 Disconnect the battery negative lead.

6 Disconnect the electrical wiring plugs from

the solenoid within the door cavity.

7 Disconnect the solenoid from the lock lever

by removing the clip.

8 Unscrew the two bolts which secure the

solenoid to the door and remove it.

9 Renew the solenoid or switch as necessary.

10 Refitting is a reversal of removal.

11 Refer to Section 10 for details of system

fuses and relays.

33 Economy gauge

(Econometer)

2

1 This device is fitted to ES (energy saving)

models and indicates to the driver the fuel

consumption (in litres per 100 km) coupled

with a needle which moves over coloured

sections of a dial to make the driver aware

that his method of driving is either conducive

to high or low fuel consumption. Refer to

Chapter 3, Section 16.

2 The device is essentially a vacuum gauge

which also incorporates a warning lamp to

indicate to the driver when a change of gear is

required.

3 A fuel cut-out valve (see Chapter 3, Sec-

tion 11) is used in conjunction with the

economy gauge so that when the accelerator

pedal is released during a pre-determined

engine speed range, fuel supply to the engine

is stopped, but resumes when the engine

speed falls below the specified range.

LED (light emitter diode)

4 The gearchange indicator will only light up

at engine speeds in excess of 2000 rev/min

for vacuum pressures up to 600 mm Hg in 1st,

2nd and 3rd speed gears and for vacuum

pressures up to 676 mm Hg in 4th speed

gear. The light will not come on if 5th speed

gear is engaged or if the coolant temperature

is below 55ºC.

5 There is a two second delay in the light

coming on to prevent it operating during rapid

acceleration in a low gear.

6 If the LED light comes on during

deceleration it should be ignored.

Fault finding

7 A faulty economy gauge should be checked

in the following way.

8 Refer to Section 21 and remove the

instrument panel.

9 Disconnect the economy gauge L

connector and then connect a test lamp

between the BN cable contact and earth. If

the lamp comes on then the gauge supply

circuit is not open. If the lamp does not come

on, check all connections in the supply cable

which comes from the interconnecting unit of

the electrical system, also Fuse No 12.

10 Now connect a voltmeter between the

white cable and earth. Check the voltage with

the engine not running, but the ignition

switched on. It should be between 0.7 and

0.9 volt. If the reading varies considerably

from that specified, check the connections

between the economy gauge and the fuel

cut-out device control unit. If the fault cannot

be rectified, renew the ignition control unit

(Digiplex system, see Chapter 4).

11 Now check the closed throttle valve plate

switch by connecting a voltmeter between the

brown and BN cables of the L connector. With

the valve plate open, there should be no

reading, but with it open, voltage should be

indicated.

12 Failure to conform as described will be

due to a faulty earth in the switch or a faulty

fuel cut-out device control unit.

13 A further test of the throttle valve plate

switch may be carried out by disconnecting

the multi-plug from the fuel cut-out device

control unit.

14 Connect a test lamp to contact 4 (positive

battery terminal). The lamp should come on,

when the engine is idling or the accelerator

released. If it does not, renew the throttle

valve plate switch.

15 Connect a tachometer to the brown/white

cable contact in the L connector and record

the engine speed with the engine running. If

no reading is obtained, renew the Digiplex

ignition control unit which must be faulty.

34 Check control (warning

module) system

2

1 This is fitted into the instrument panel of

certain models to provide a means of

checking the operation of many electrical

circuits and other systems in the interest of

safety. Sensors are used where appropriate.

2 The following components are not

monitored by the system, but have separate

warning lamps:

Handbrake “on”

Choke in use

Low engine oil pressure

Battery charge indicator

3 The multi-functional electronic device

automatically checks the following functions

whether the engine is running or not:

Coolant level

Disc pad wear

Door closure

Engine oil level

Front parking lamps

Rear foglamps

Stop lamps

4 The check information is stored by the

system monitor until the engine is started

when the display panel then indicates the

situation by means of the LEDs (light emitter

diodes) and the general lamp.

5 If all functions are in order, the green panel

lamp will come on when the ignition key is

turned and will go out after two to three

seconds.

6 If some functions are not in order, then the

red panel lamp will come on also the

appropriate LED.

Sensors - checking

7 If a fault signal occurs which is

subsequently found to be incorrect, first

check the wiring connections between the

9•12 Electrical system

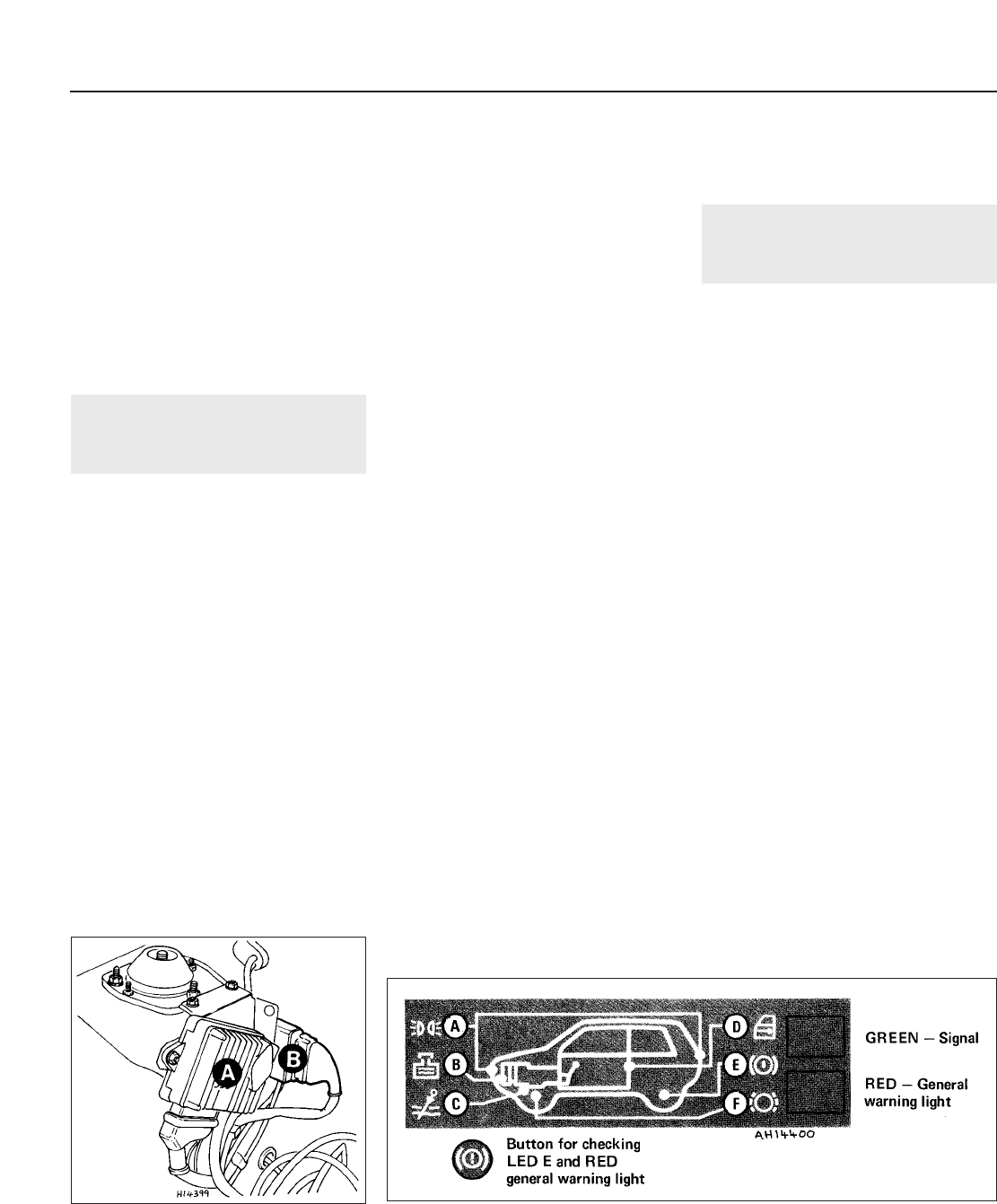

Fig. 9.15 Check system control panel (Sec 34)

A Parking lamps

B Coolant level

C Engine oil level

D Door closure

E Brake fluid level

F Disc pad wear

Fig. 9.14 Location of control units (Sec 33)

A Digiplex ignition system control unit

B Fuel cut-out valve control unit