TROUBLESHOOTING LBI-38988

Rev. B 29

TROUBLESHOOTING

The hardware used in the GETC is extremely reliable,

making component failure the unlikely cause of most

problems. The most common causes of problems are

programming errors and interface connections.

Use the following guidelines when troubleshooting a

GETC on site:

1. Verify the operation of front panel LEDs. This

can be done by performing the Operational

Checkout and verifying the LED indications.

GETCs using 349A9607 Group 4 software may

also indicate the specific cause of the failure, refer

to Failure Mode.

2. Verify that all cables are properly connected and

secure.

3. Verify the GETC’s personality is properly

programmed for the specific application. Refer to

TQ-3357, PC Programmer and SRN1060 (SRN

1024 if using 19A705595G8 software).

4. Verify the Turbo Board is properly configured if

applicable. Refer to LBI-38822 and SRN 1062.

5. If you suspect that the GETC has failed, replace

the it with a known good unit properly configured

for this application. Recheck all software and

personality parameters and checkout the GETC’s

operation. If the GETC functions properly, repair

or replace the malfunctioning GETC according to

the instructions in LBI-38894.

FAILURE MODE

With the introduction of 349A9607 Group 4 software,

the GETC is able to indicate a specific failure via the front

panel LEDs. Prior to group 4 software, a failure is

indicated by incorrect LEDs, but the GETC did not indicate

the root cause. The failure modes listed in Table 14

describe the LED displays and their corresponding failure

mode interpretation.

In all 3 failure modes, the channel is completely taken

out of service. This allows the System Manager in Fully

Trunked systems to display a channel failure. In Trunked

Failsoft, the channel is removed from service to avoid using

the bad channel.

CHANNEL ACTIVITY LOGGER

Another diagnostic feature introduced with the

349A9607 Group 4 software is the Channel Activity

Logger. This feature allows the GETC to supply

information about what it sees from its inputs: the RF

receiver, phone line receiver, station interface I/O.

Additionally, the GETC can supply internal event

information about what the GETC is doing. For example,

if the GETC tries to train its Rockwell modem, it will print

a message “MODEM TRAINING STARTED,” and when

the modem becomes trained, it will print “MODEM

TRAINING COMPLETED.” In General, the information

supplied by the Channel Activity Logger is EDACS specific

and in some cases may need technical assistance for

interpretation. For detailed instructions on using the

Channel Activity Logger, refer to SRN1060 and PC

Programmer TQ-3357 V4.03 (or later).

IN CASE OF DIFFICULTY

If you are unable to resolve a problem to your

satisfaction, then contact the Ericsson Technical Assistance

Center (TAC) at 1-800-528-7711 (outside USA, 804-528-

7711).

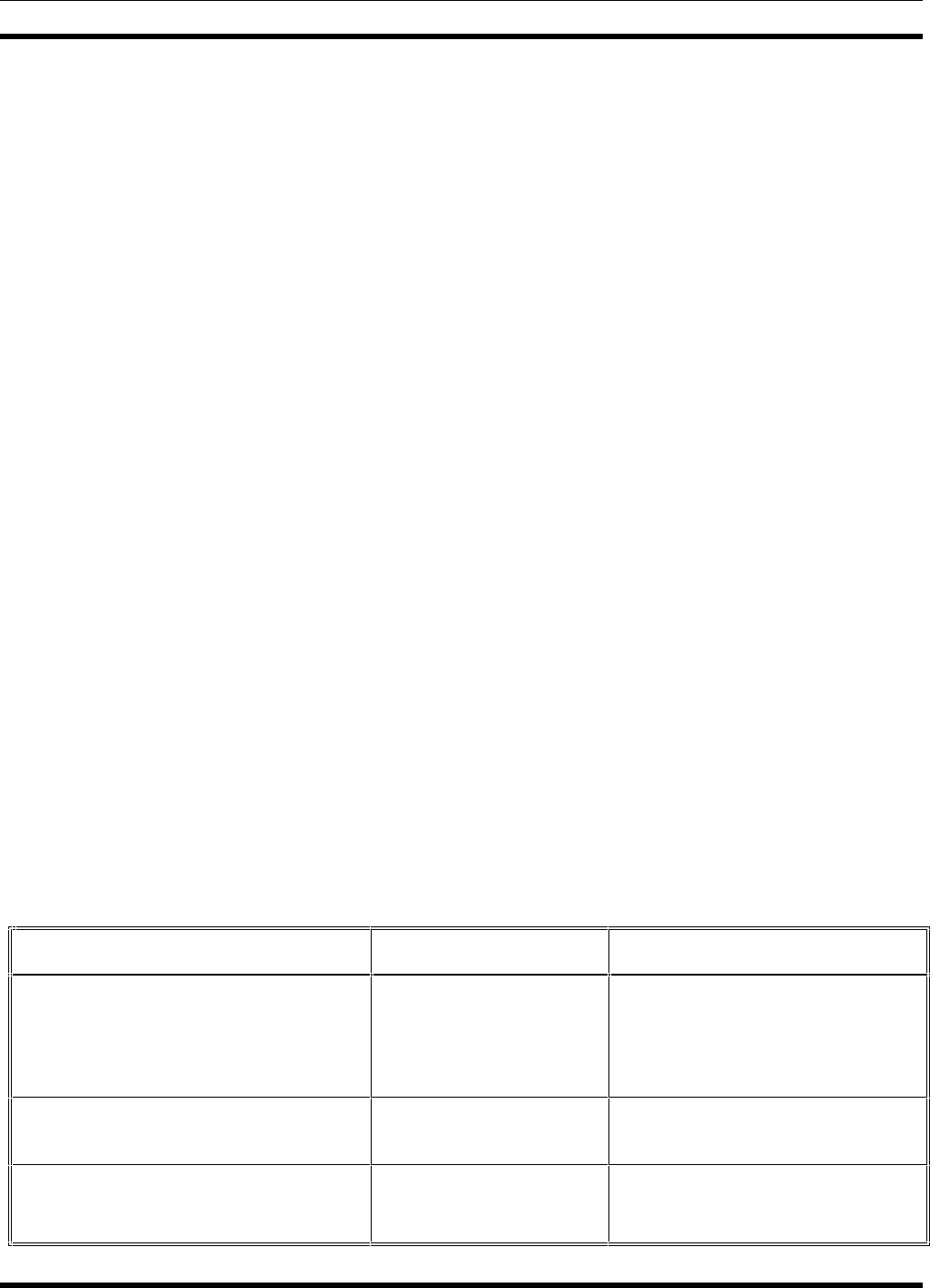

Table 14 - Failure Modes

LED DISPLAY FAILURE MODE POSSIBLE FAILURE CAUSE

LED 7 (only ) - Flashing

Flashing rate = 1 second

Quick synthesizer reload after every 5 flashes

of LED 7 (quick flash of LEDs 3, 4, and 5)

GETC is unable to cause a

synthesizer lock.

Bad synthesizer, Bad 10V Station Power

Supply, incorrect operation of MASTER

III Station Module, J26 Incorrect.

LED 6 (only) - Flashing

Flashing rate = 1 second

GETC has detected a PA Low

Power Alarm condition.

Bad PA, incorrect adjustment of R141,

uncalibrated Power Sensor.

LED 6 & 7 (only) - Flashing simultaneously

Flashing rate = 1 second

GETC has detected failure of

Turbo Board.

Turbo Board switches not in operational

position (toward rear of GETC), wrong

turbo software, bad turbo card.